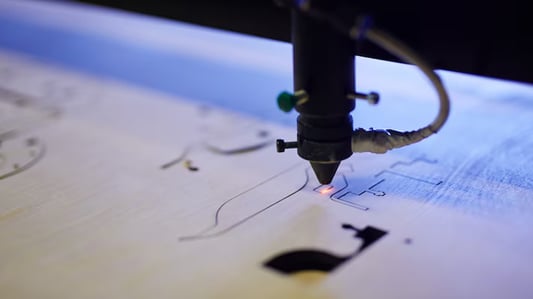

What is a cnc laser pipe cutter?A CNC laser pipe cutter is a specialized machine used for cutting pipes with precision and accuracy. It uses a laser beam to cut through the material, making it ideal for a wide range of industries such as automotive, aerospace, and construction.How Does a CNC Laser Pipe Cutter Work?CNC laser pipe cutters work by using a computer-controlled system to guide the laser beam along the pipe's surface. The laser beam heats up the material, causing it to melt and then vaporize, creating a clean and precise cut.The Benefits of Using a CNC Laser Pipe Cutter There are numerous benefits to using a CNC laser pipe cutter, including increased efficiency, cost-effectiveness, and the ability to produce complex and intricate designs. These machines are also highly reliable and require minimal maintenance.Applications of CNC Laser Pipe CuttersCNC laser pipe cutters are commonly used in industries such as metal fabrication, automotive manufacturing, and shipbuilding. They can be used to cut various types of pipes, including stainless steel, aluminum, and copper, making them versatile tools for a wide range of applications.Choosing the Right CNC Laser Pipe CutterWhen selecting a CNC laser pipe cutter, it's important to consider factors such as the maximum pipe diameter it can handle, the power of the laser beam, and the level of automation and precision required for your specific application. Technology Advances in CNC Laser Pipe CuttersRecent advancements in CNC laser pipe cutters have led to improved cutting speeds, better precision, and increased flexibility in terms of the types of materials that can be cut. These technological advances have made these machines even more efficient and versatile.Cost Considerations for CNC Laser Pipe CuttersThe cost of a CNC laser pipe cutter can vary depending on factors such as the machine's capabilities, brand, and size. It's important to weigh the initial investment against the potential long-term benefits and savings in production costs.Training and Support for CNC Laser Pipe Cutter OperatorsOperators of CNC laser pipe cutters require specialized training to ensure safe and efficient operation of the machines. Many manufacturers offer training programs and ongoing technical support to help operators maximize the performance of their CNC laser pipe cutters.Maintenance and Servicing of CNC Laser Pipe CuttersProper maintenance and servicing of CNC laser pipe cutters are essential to ensure optimal performance and longevity of the machines. Regular cleaning, calibration, and inspections are necessary to prevent downtime and maintain cutting quality.The Future of CNC Laser Pipe Cutting TechnologyAs technology continues to advance, the future of CNC laser pipe cutting looks promising. With ongoing innovations in automation, integration with CAD/CAM software, and improved material handling capabilities, CNC laser pipe cutters will continue to play a vital role in the manufacturing industry.Quote Inquirycontact us