tube fiber lasers are advanced cutting machines that use fiber optic technology to deliver precise and efficient results. These lasers are widely used across various industries for a range of cutting applications thanks to their speed, accuracy, and versatility. In this article, we will explore the key features and benefits of tube fiber lasers to help you understand why they are a valuable investment for your business.

High Precision Cutting

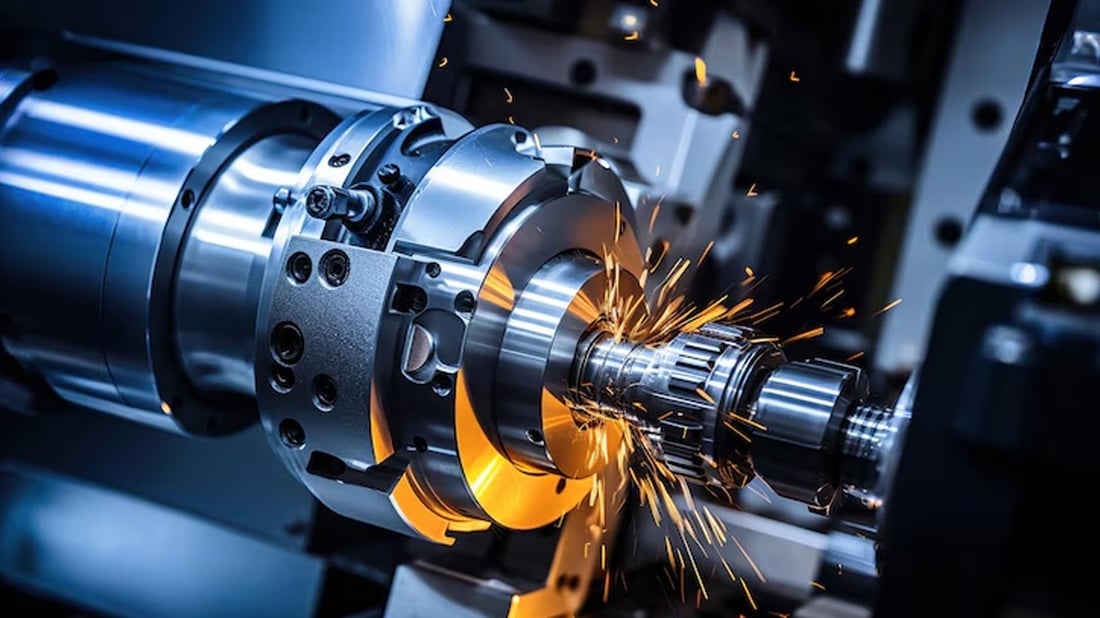

One of the main advantages of tube fiber lasers is their ability to achieve high precision cutting. The focused beam of light generated by the laser can cut through a variety of materials with incredible accuracy, making it ideal for intricate designs and complex shapes. Whether you are working with metal, plastic, or other materials, tube fiber lasers can deliver clean and precise cuts every time.

Increased Productivity

Tube fiber lasers are known for their speed and efficiency, allowing for faster production times and increased productivity. The high cutting speeds and rapid processing capabilities of these lasers mean that you can complete more projects in less time, ultimately leading to higher output and improved profitability for your business.

Cost-Effective Solution

While tube fiber lasers may require a significant initial investment, they offer long-term cost savings due to their efficiency and low maintenance requirements. These lasers have a longer lifespan than traditional cutting machines and consume less energy, helping you reduce operational costs and maximize your ROI in the long run.

Flexible Applications

Tube fiber lasers are highly versatile and can be used for a wide range of cutting applications across different industries. Whether you are in the automotive, aerospace, or electronics sector, these lasers can handle various materials and thicknesses, making them suitable for diverse cutting tasks. From prototyping to mass production, tube fiber lasers can adapt to your specific needs.

Simple Operation

Despite their advanced technology, tube fiber lasers are easy to operate and maintain, making them user-friendly for operators of all skill levels. With intuitive controls and automated features, these machines can streamline the cutting process and minimize the risk of errors, ensuring consistent and reliable results every time.

Environmental Friendly

Tube fiber lasers are environmentally friendly cutting solutions that produce minimal waste and emissions compared to traditional cutting methods. By using a focused beam of light to cut through materials, these lasers eliminate the need for additional tools or chemicals, reducing your carbon footprint and promoting sustainable manufacturing practices.

Enhanced Safety

Safety is a top priority in any manufacturing environment, and tube fiber lasers are designed with several safety features to protect operators and prevent accidents. From automatic shutdown mechanisms to protective enclosures, these lasers are equipped with safeguards that adhere to industry standards and regulations, ensuring a secure working environment for your employees.

Customization Options

Tube fiber lasers offer a high degree of customization options to meet your specific cutting requirements. Whether you need to adjust the cutting speed, focus depth, or beam intensity, these lasers can be tailored to suit different materials and thicknesses, giving you more control over the cutting process and the quality of the final product.

Technical Support

Investing in tube fiber lasers also means gaining access to comprehensive technical support and training from manufacturers and suppliers. Whether you need assistance with machine setup, troubleshooting, or maintenance, expert technicians can provide guidance and resources to help you optimize the performance of your laser system and maximize its potential.

Future Prospects

As technology continues to advance, tube fiber lasers are expected to evolve and improve further, offering new features and capabilities for enhanced cutting performance. By staying informed about the latest developments in laser technology and upgrading your equipment as needed, you can stay ahead of the competition and achieve greater success in your industry.