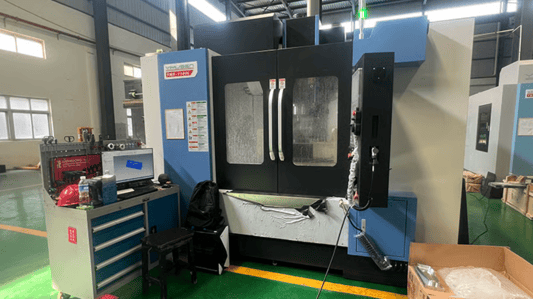

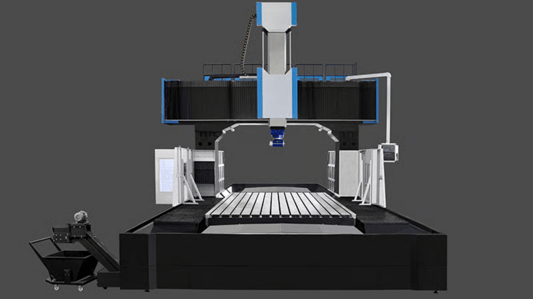

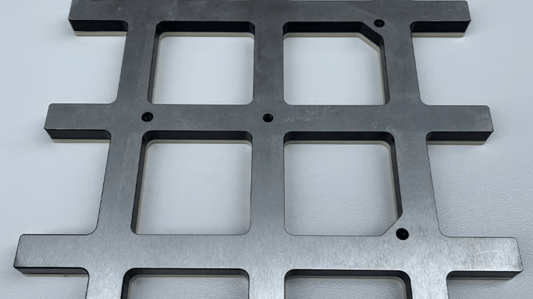

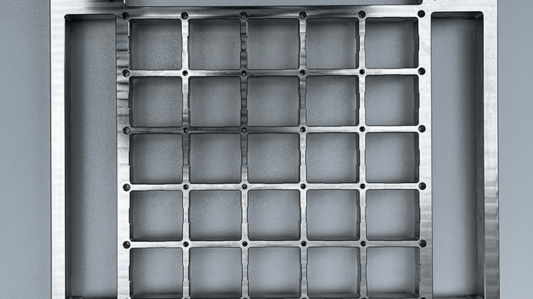

Introduction to the Double column vertical machining center VMC-1160 The Double Column Vertical Machining Center VMC-1160 represents a significant advancement in precision machining technology. Designed for heavy-duty and high-precision manufacturing tasks, this machine tool excels in the production of large, complex components. Its dual-column structure offers enhanced stability and rigidity, making it an ideal choice for industries demanding top-tier machining accuracy and efficiency. Structural Advantages of the Double Column Design The standout feature of the Double Column Vertical Machining Center VMC-1160 is its double column architecture, providing superior support and minimizing vibrations during operation. This design ensures consistent cutting performance and extends tool life, thereby improving overall machining productivity. Unlike conventional single-column machines, the VMC-1160’s rigid frame enhances dimensional accuracy, especially for large workpieces. High Precision and Accuracy Capabilities Equipped with advanced control systems and precision ball screws, the Double Column Vertical Machining Center VMC-1160 delivers exceptional machining accuracy. The machine achieves tight tolerances, essential for aerospace, automotive, and mold-making industries. Its stability reduces thermal displacement and repetition errors, guaranteeing reliable results throughout long production runs. Spindle Performance and Versatility The Double Column Vertical Machining Center VMC-1160 features a powerful spindle designed to handle a wide range of cutting conditions. Offering high-speed rotation and robust torque, the spindle caters to various materials including hardened steel, aluminum, and composites. This versatility allows manufacturers to implement multiple machining processes such as milling, drilling, and tapping within a single setup. User-Friendly CNC Control Interface Modern CNC control systems integrated into the VMC-1160 facilitate ease of programming and operation. The user-friendly interface supports complex machining cycles with minimal input, reducing setup time and operator fatigue. Furthermore, remote diagnostics and real-time monitoring capabilities contribute to enhanced machine management and reduced downtime. Optimized Workspace and Tool Capacity The Double Column Vertical Machining Center VMC-1160 boasts a spacious worktable and a high-capacity tool magazine. This enables the handling of larger components and complex tool changes without interrupting production. The ample workspace coupled with automatic tool changers increases machining efficiency and supports multi-dimensional workpieces with ease. Applications Across Key Industries Industries such as aerospace, automotive, heavy machinery, and die/mold manufacturing benefit immensely from the Double Column Vertical Machining Center VMC-1160. Its ability to machine large parts with precision suits the fabrication of engine blocks, turbine components, and customized molds. The machine’s adaptability to specific industry requirements makes it a valuable asset for diverse manufacturing tasks. Maintenance and Durability Considerations Designed for longevity, the VMC-1160 incorporates high-quality components that reduce wear and mechanical failures. The machine’s maintenance protocols are streamlined through predictive diagnostics and modular parts replacement. These features minimize operational interruptions and safeguard investment by ensuring prolonged service life. Energy Efficiency and Environmental Impact In response to growing demands for sustainable manufacturing, the Double Column Vertical Machining Center VMC-1160 integrates energy-efficient motors and systems. Optimized power consumption and reduced waste contribute to lower operating costs and a smaller environmental footprint, aligning with modern green manufacturing standards. Future Trends and Technology Integration Advanced iterations of the Double Column Vertical Machining Center VMC-1160 increasingly incorporate Industry 4.0 technologies such as IoT connectivity, AI-driven process optimization, and adaptive control. These innovations promise further enhancements in machine intelligence, productivity, and predictive maintenance, keeping the VMC-1160 competitive in the evolving manufacturing landscape. Quote Inquirycontact us