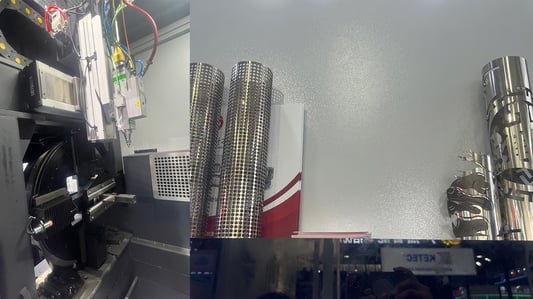

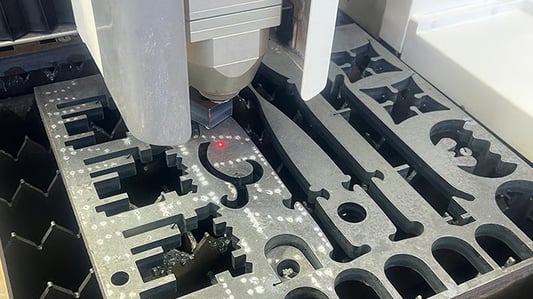

What is Round Pipe Laser Notching? Round pipe laser notching is an advanced metal fabrication technique used to create precise, clean notches in round pipes. Utilizing high-powered laser beams, this process enables the accurate cutting of complex shapes and angles in tubing, which is critical for applications in structural frameworks, automotive parts, and piping systems. The laser’s focused energy vaporizes material without physical contact, reducing deformation and enhancing edge quality compared to traditional mechanical notching.Advantages of Laser Notching Over Traditional Methods Laser notching offers numerous advantages over conventional methods such as milling or mechanical cutting. It provides superior precision with minimal material waste and excellent repeatability. The process is faster and requires less manual intervention, reducing labor costs. Moreover, the laser’s non-contact nature minimizes thermal distortion and mechanical stress on pipes, preserving their structural integrity — a vital factor in industrial applications where pipe strength is critical.Types of Lasers Used in Round Pipe Laser Notching Fiber lasers, CO2 lasers, and Nd:YAG lasers are commonly used for round pipe laser notching. Fiber lasers are increasingly popular due to their high efficiency, low maintenance, and ability to cut reflective metals like stainless steel and aluminum. CO2 lasers excel in cutting thicker materials, while Nd:YAG lasers provide good beam quality for intricate notching tasks. Selecting the right laser depends on pipe material, thickness, and notch complexity.Applications in Structural Steel Fabrication In structural steel fabrication, round pipe laser notching is essential for creating joints and connections with precision. Notches must fit perfectly for seamless welding and assembly of pipe frameworks in buildings, bridges, and industrial supports. The accuracy of laser notching ensures stronger joints, improved safety, and reduced rework, contributing to higher overall project efficiency in construction and manufacturing environments.Impact on the Automotive Industry The automotive industry benefits significantly from round pipe laser notching by enabling lightweight yet strong tubular components. Exhaust systems, roll cages, and chassis pipes often require custom notching to fit together precisely. Laser notching allows for complex designs that optimize vehicle performance and safety without compromising production speed or quality, supporting the demand for innovative automotive engineering.Material Compatibility and Flexibility Round pipe laser notching is compatible with a wide range of metals including carbon steel, stainless steel, aluminum, and alloys. This versatility makes it suitable for diverse industries such as aerospace, marine, and energy. Adjusting laser parameters like power and speed allows customization to different pipe materials and thicknesses, ensuring consistent notch quality regardless of the substrate.Automation and Integration with CNC Systems Modern round pipe laser notching machines are commonly integrated with CNC (Computer Numerical Control) systems, enabling fully automated notching processes. This integration enhances precision, repeatability, and throughput by using pre-programmed notch geometries and sequences. Automation reduces human error and allows seamless production of complex assemblies, making it ideal for high-volume manufacturing lines.Quality Control and Dimensional Accuracy Laser notching ensures exceptional dimensional accuracy, often within microns, which is critical for tight-tolerance assembly work. Automated inspection systems can be combined with laser notching to verify notch dimensions in real time, ensuring each cut meets stringent quality standards. This reliability minimizes downstream issues during fitting and welding phases, improving overall product quality.Environmental and Cost Considerations Round pipe laser notching is an environmentally friendly fabrication method due to its minimal material waste and low energy consumption compared to mechanical cutting tools. Additionally, it reduces the need for secondary finishing processes since laser cuts produce clean edges without burrs. These efficiencies translate into lower operational costs and a smaller carbon footprint for manufacturing facilities.Emerging Trends and Future Developments Advancements in laser technologies, such as increased power outputs and improved beam control, continue to push the capabilities of round pipe laser notching. Integration with Industry 4.0 concepts, including real-time data monitoring and AI-driven process optimization, is revolutionizing production. Future developments promise even greater speed, precision, and versatility, making laser notching an indispensable tool for metal fabrication industries worldwide. Quote Inquirycontact us