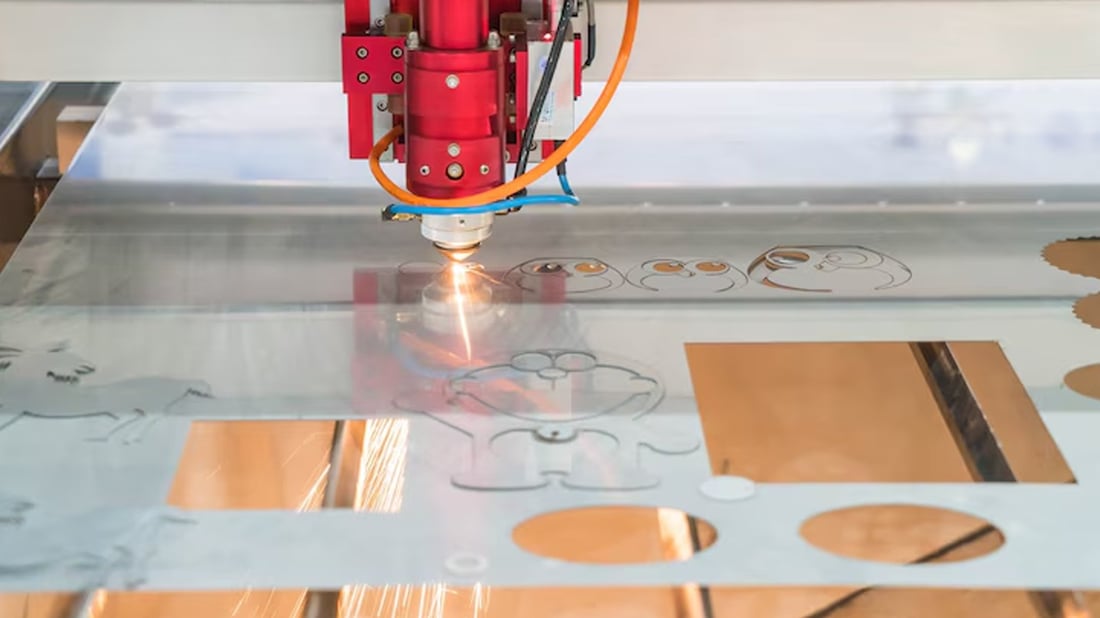

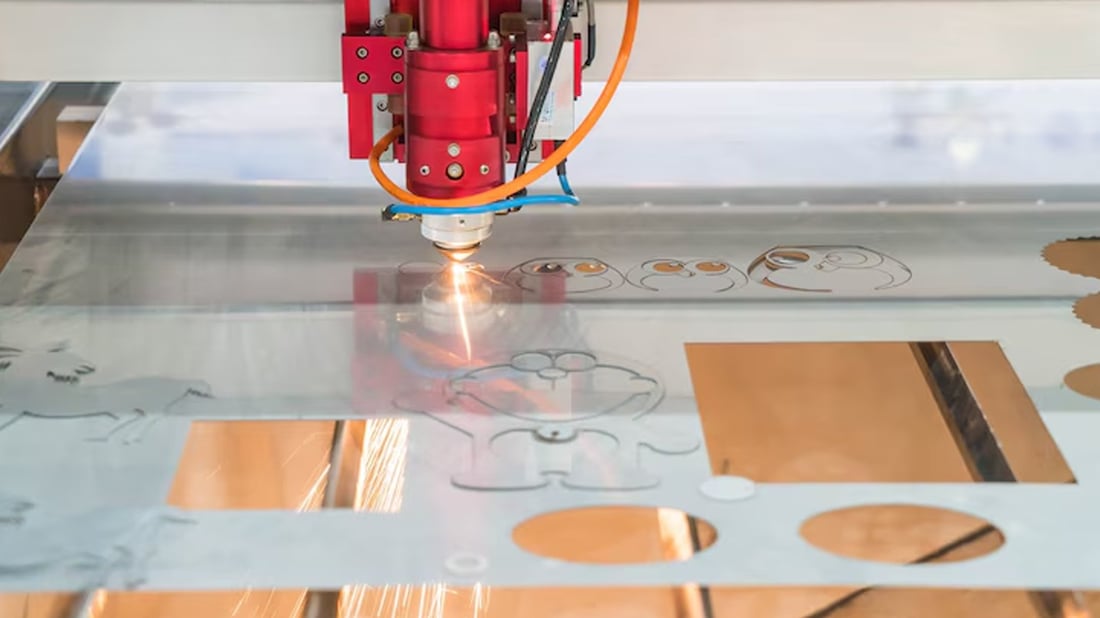

Tube fiber laser cutting machines are advanced tools used in the manufacturing industry to precisely cut through a variety of materials. These machines utilize a high-powered laser beam to slice through tubes and pipes with high accuracy and speed.

Benefits of Using a Tube Fiber Laser Cutting Machine

One of the main advantages of using a tube fiber laser cutting machine is its superior cutting quality. The laser beam creates clean and precise cuts, resulting in high-quality finished products. Additionally, these machines are highly efficient and can significantly reduce production time.

Applications of Tube Fiber Laser Cutting Machines

Tube fiber laser cutting machines are commonly used in industries such as automotive, aerospace, and construction. They are suitable for cutting a wide range of materials, including steel, aluminum, and copper. These machines are versatile and can be used for various applications, such as cutting tubes for exhaust systems or structural components.

How Does a Tube Fiber Laser Cutting Machine Work?

Tube fiber laser cutting machines work by directing a focused laser beam onto the surface of the material to be cut. The high energy density of the laser beam melts or vaporizes the material, creating a clean and precise cut. These machines are equipped with advanced software that controls the cutting process and allows for customization of cutting parameters.

Key Features to Consider When Choosing a Tube Fiber Laser Cutting Machine

When selecting a tube fiber laser cutting machine, it is essential to consider factors such as laser power, cutting speed, and precision. Higher laser power allows for cutting through thicker materials, while faster cutting speeds improve efficiency. Precision is crucial for achieving accurate cuts and minimizing material waste.

Types of Tube Fiber Laser Cutting Machines

There are several types of tube fiber laser cutting machines available on the market, including standalone machines and automated systems. Standalone machines are suitable for small-scale production or prototyping, while automated systems are designed for high-volume manufacturing. The choice of machine depends on the specific needs of the production environment.

Maintenance and Care for Tube Fiber Laser Cutting Machines

To ensure optimal performance and longevity of a tube fiber laser cutting machine, regular maintenance is essential. This includes cleaning the machine regularly, checking and replacing worn parts, and calibrating the laser system. Proper care and maintenance can extend the lifespan of the machine and prevent costly repairs.

Advancements in Tube Fiber Laser Cutting Technology

Recent advancements in tube fiber laser cutting technology have led to the development of more efficient and precise machines. New features such as automatic material detection, real-time monitoring, and remote operation capabilities have improved the overall performance and usability of these machines. Manufacturers are constantly innovating to meet the evolving needs of the industry.

Factors Influencing the Cost of a Tube Fiber Laser Cutting Machine

The cost of a tube fiber laser cutting machine can vary depending on several factors, including laser power, cutting capacity, and additional features. Higher-powered machines with advanced capabilities are typically more expensive than basic models. It is essential to carefully assess the specific requirements of the production process to determine the most cost-effective option.

Conclusion

Tube fiber laser cutting machines are essential tools in the manufacturing industry, offering high precision, efficiency, and versatility. By understanding the key features, applications, and advancements in this technology, manufacturers can make informed decisions when choosing a machine for their production needs.

Quote Inquiry

contact us