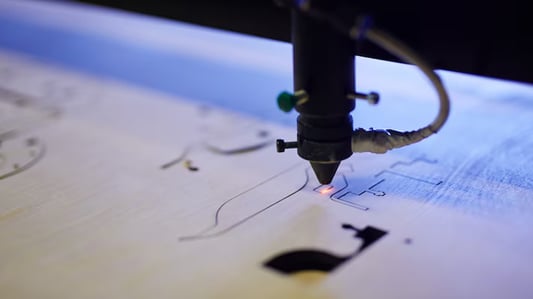

Introduction to small CNC machining centre Small CNC machining centres are compact and versatile machines that are used for precision manufacturing. These machines are perfect for small to medium-sized businesses that require high-quality, repetitive tasks such as drilling, milling, and cutting. Small CNC machining centres are known for their efficiency, accuracy, and reliability, making them an essential tool for any modern workshop or manufacturing facility.Precision Cutting and MillingOne of the main advantages of using a small CNC machining centre is its ability to perform precision cutting and milling tasks with high accuracy. These machines are equipped with advanced software and control systems that allow the operator to program and execute complex machining operations with ease. This results in better quality products and faster production times.Cost-Effective SolutionSmall CNC machining centres are a cost-effective solution for businesses looking to improve their manufacturing processes. These machines require minimal manual labor, which helps reduce labor costs and increase productivity. Additionally, the precision and accuracy of small CNC machining centres result in less waste material, ultimately saving the business money in the long run.Space-Saving DesignSmall CNC machining centres are designed to be compact and space-saving, making them ideal for workshops with limited space. These machines can easily fit into small spaces without compromising on performance or functionality. This makes them perfect for small businesses or hobbyists who have limited space but still require high-quality machining capabilities.Versatility in Machining OperationsDespite their small size, CNC machining centres are incredibly versatile machines that can perform a wide range of machining operations. From drilling and milling to cutting and engraving, these machines can handle various tasks with precision and accuracy. This versatility makes small CNC machining centres a valuable asset for businesses in various industries.Increased Productivity and EfficiencySmall CNC machining centres are known for their ability to increase productivity and efficiency in manufacturing processes. These machines can run continuously without the need for constant supervision, allowing businesses to maximize their production output. The automation capabilities of small CNC machining centres also help reduce the risk of errors and delays in production.Customization and PersonalizationSmall CNC machining centres allow businesses to easily customize and personalize their products according to customer requirements. These machines can quickly adapt to design changes and produce unique, one-of-a-kind products with high precision and accuracy. This level of customization helps businesses stand out in the market and attract more customers.Quality Control and ConsistencyWith small CNC machining centres, businesses can ensure consistent quality control in their manufacturing processes. These machines are capable of producing identical parts with minimal variation, ensuring that each product meets the required specifications. This level of consistency helps businesses maintain high-quality standards and build a strong reputation in the industry.Improved Safety and Reduced RisksSmall CNC machining centres are equipped with advanced safety features that help reduce the risk of accidents and injuries in the workplace. These machines have protective enclosures, emergency stop buttons, and safety sensors that ensure safe operation at all times. By investing in a small CNC machining centre, businesses can create a safer working environment for their employees.Future-Proof InvestmentInvesting in a small CNC machining centre is a future-proof decision for businesses looking to stay competitive in the market. These machines are built to last and can adapt to changing industry trends and technologies. By incorporating a small CNC machining centre into their operations, businesses can enhance their manufacturing capabilities and position themselves for long-term success.Quote Inquirycontact us