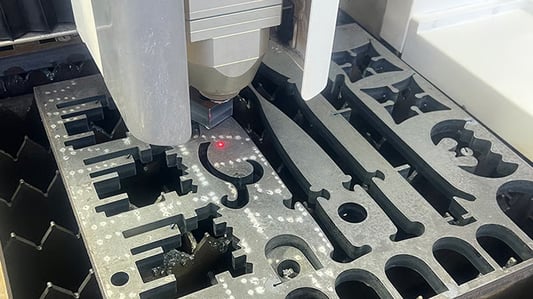

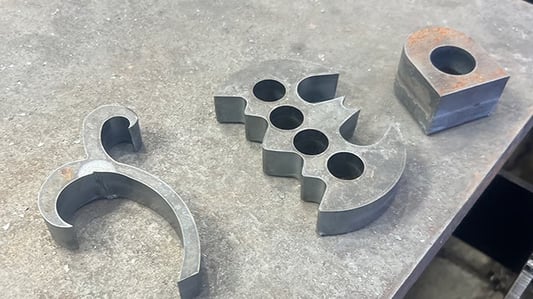

When it comes to precision machining, CNC milling machines are at the forefront of technology and innovation. These machines are instrumental in the manufacturing industry, helping to create intricate and complex parts with incredible accuracy. In this article, we will delve into the world of CNC milling machines, exploring their capabilities, benefits, and applications.What is a CNC Milling Machine?A CNC milling machine is a computer-controlled machine tool that can mill, drill, and cut various materials with precision. The machine operates on predefined computer programs that dictate the cutting movements and tool paths. This automation enables highly accurate and consistent results, making CNC milling machines ideal for prototyping and production runs.Types of CNC Milling MachinesThere are several types of CNC milling machines, each designed for specific purposes and applications. Some common types include vertical milling machines, horizontal milling machines, and gantry mills. Each type has its unique strengths and capabilities, catering to different machining requirements.Advantages of CNC Milling MachinesCNC milling machines offer a myriad of advantages over traditional manual machining methods. Some key benefits of CNC milling machines include increased precision, efficiency, repeatability, and versatility. These machines can also work around the clock with minimal human intervention, maximizing productivity.Applications of CNC Milling MachinesCNC milling machines are used across various industries for a wide range of applications. From aerospace and automotive industries to medical and electronics sectors, CNC milling machines play a crucial role in manufacturing intricate components. These machines are capable of producing complex shapes and designs with ease.Features of CNC Milling MachinesModern CNC milling machines come equipped with advanced features and technologies that enhance precision and performance. Some common features include multi-axis capabilities, high-speed spindles, automatic tool changers, and integrated coolant systems. These features contribute to the efficiency and accuracy of CNC milling operations.Choosing the Right CNC Milling MachineWhen selecting a CNC milling machine for your machining needs, it is essential to consider factors such as the type of materials to be machined, desired precision levels, production volume, and budget. Understanding your specific requirements will help you choose the right machine that meets your needs.Maintenance and Care of CNC Milling MachinesProper maintenance and care are crucial for ensuring the longevity and efficiency of CNC milling machines. Regularly scheduled maintenance tasks such as cleaning, lubrication, and calibration are necessary to keep the machine in optimal condition. Additionally, operators should follow safety protocols to prevent accidents and damage to the machine.Future Trends in CNC Milling MachinesThe field of CNC milling machines is constantly evolving, with new technologies and innovations shaping the future of machining. Future trends in CNC milling machines include the integration of artificial intelligence, automation, and predictive maintenance capabilities. These advancements aim to further enhance precision, efficiency, and productivity in machining operations.ConclusionIn conclusion, CNC milling machines are indispensable tools in the manufacturing industry, offering unparalleled precision, efficiency, and versatility. With their advanced capabilities and innovative features, CNC milling machines continue to push the boundaries of what is possible in precision machining. By understanding the fundamentals of CNC milling machines and staying abreast of the latest trends, manufacturers can harness the full potential of these cutting-edge machines.Quote Inquirycontact us