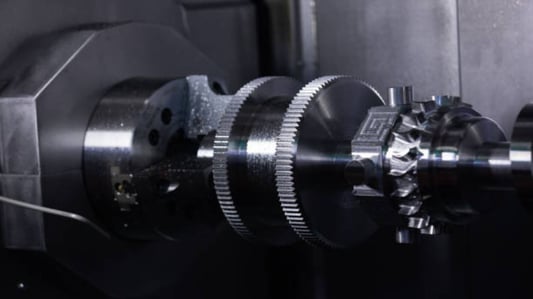

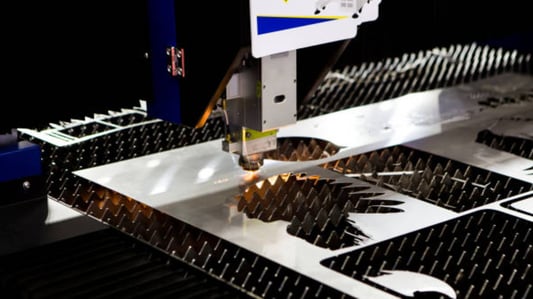

Introductiondouble column cnc milling machines are designed to handle large amounts of machining tasks with precision and speed. These machines are perfect for producing large-sized parts that require high precision. In this article, we'll give you an in-depth look at double column CNC milling machines and how they work.What is a double column CNC milling machine?A double column CNC milling machine is a type of machine that uses multiple milling heads to cut various materials. The machine has a gantry structure with two columns that support the milling heads. These machines are known for their high precision and excellent performance.Functionality of Double Column CNC Milling MachineDouble column CNC milling machines come with a range of features that make them highly functional. Some of these features include the ability to control the depth of the cut, adjust the spindle speed, and control the feed rate. The machine has a high accuracy which is critical for precision machining.Benefits of Double Column CNC Milling MachineOne of the main benefits of the double column CNC milling machine is the ability to produce high-quality parts with very tight tolerances. The machine can produce large parts that are too difficult to produce with other machines. It also allows you to perform multiple cutting operations in real-time.Applications of Double Column CNC Milling MachineDouble column CNC milling machines are used in a wide range of industries including aerospace, automotive, and medical. These machines are excellent for producing various parts such as engine blocks, crankshafts, and turbines. They are ideal for producing large parts that are critical to a project.Features of Double Column CNC Milling MachineDouble column CNC milling machines come with a range of features that make them versatile. These machines can handle a range of materials including alloys, composites, plastics, and wood. They have a high feed rate which increases productivity and saves time.How to Choose the Right Double Column CNC Milling MachineChoosing the right double column CNC milling machine depends on the specific needs of your project. Factors to consider include the size of the materials, the accuracy, and the complexity of the parts. You should also consider the type of materials you'll be working with and the level of precision required.Operation of Double Column CNC Milling MachineOperating a double column CNC milling machine requires specialized training. You need to be familiar with the various controls and functions, as well as safety precautions to take. Always consult the manufacturer's manual for specific instructions on how to operate the machine.Maintenance of Double Column CNC Milling MachineTo keep your double column CNC milling machine in good working order, you need to perform regular maintenance. This includes cleaning and lubricating the machine, checking the electrical connections, and inspecting the cutting edges for damage.ConclusionDouble column CNC milling machines are essential machines for precision machining tasks that require tight tolerances and accuracy. These machines are versatile and can handle a variety of materials, making them an ideal choice for a range of industries. If you're considering investing in one, make sure to choose the right machine for your specific needs, follow all safety protocols, and perform regular maintenance to ensure a long service life.Quote InquiryContact us!