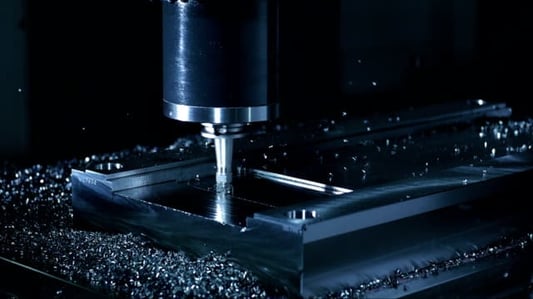

The Ultimate Guide to cnc engraver cutter: Everything You Need to KnowAn Introduction to CNC Engraver CutterCNC engraver cutter is a revolutionary technology that has transformed the world of engraving and cutting. This advanced machine utilizes computer numerical control (CNC) to accurately and precisely engrave or cut various materials such as wood, metal, plastic, and more. In this comprehensive guide, we will delve into the various aspects of CNC engraver cutter and its applications in different industries.The Working Principles of CNC Engraver CutterAt its core, a CNC engraver cutter consists of a cutting tool, a workpiece, and a computer-controlled system. The cutting tool, which can be a rotating bit or a laser, is guided by the computer-controlled system to move in different directions and depths, creating intricate designs or cutting through the material. The computer-controlled system interprets the design file and translates it into precise movements for the cutting tool.The Benefits of Using CNC Engraver CutterCNC engraver cutter offers numerous advantages over traditional engraving and cutting methods. Firstly, it provides exceptional precision and accuracy, ensuring consistent results with every project. Secondly, it allows for intricate and complex designs that would be challenging to achieve manually. Additionally, CNC engraver cutter reduces the risk of human error and increases productivity.Applications of CNC Engraver CutterCNC engraver cutter finds applications in a wide range of industries. In the woodworking industry, it is used for creating intricate designs and patterns on furniture, doors, and cabinetry. In the metalworking industry, it is utilized for engraving serial numbers, logos, or designs on metal parts. The signage industry benefits from CNC engraver cutter for producing high-quality signs and lettering. Furthermore, it has applications in the jewelry industry, where it can engrave detailed designs on precious metals.Choosing the Right CNC Engraver CutterWhen selecting a CNC engraver cutter, there are several factors to consider. Firstly, the size and dimensions of the machine should align with your specific needs and available workspace. Secondly, the power and speed of the machine will determine its efficiency and the types of materials it can handle. Thirdly, the software compatibility is crucial as it affects the ease of use and the range of design options. Lastly, consider the reputation and customer reviews of the manufacturer to ensure the reliability and durability of the machine.Maintenance and Care for CNC Engraver CutterProper maintenance and care are essential to keep your CNC engraver cutter in optimal condition. Regularly clean the machine to remove any debris or dust that may affect its performance. Lubricate the moving components to reduce friction and ensure smooth operation. Additionally, follow the manufacturer's guidelines for routine maintenance tasks and inspections.Troubleshooting Common IssuesWhile CNC engraver cutters are highly reliable, occasional issues may arise. One common problem is improper depth or uneven cuts, which can be caused by incorrect tool settings or a misaligned workpiece. To resolve this, double-check the tool settings and ensure the workpiece is properly secured. Another common issue is a dull cutting tool, resulting in poor engraving or cutting quality. Regularly inspect and replace the cutting tools as needed to maintain optimal performance.Best Practices for Safe OperationOperating a CNC engraver cutter requires caution and adherence to safety guidelines. Always wear appropriate protective gear, such as safety glasses and gloves, to protect yourself from potential hazards. Familiarize yourself with the emergency stop button and other safety features of the machine. Additionally, ensure that the work area is well-ventilated, especially when using laser-based CNC engraver cutters.Future Trends in CNC Engraver Cutter TechnologyThe field of CNC engraver cutter is constantly evolving, with new advancements and technologies on the horizon. One notable trend is the integration of artificial intelligence (AI) and machine learning algorithms into CNC engraver cutters, enabling automated design suggestions and improved performance. Additionally, the development of faster and more efficient cutting tools will further enhance productivity and precision. As technology continues to advance, CNC engraver cutters will become even more versatile and indispensable in various industries.Quote InquiryContact us!