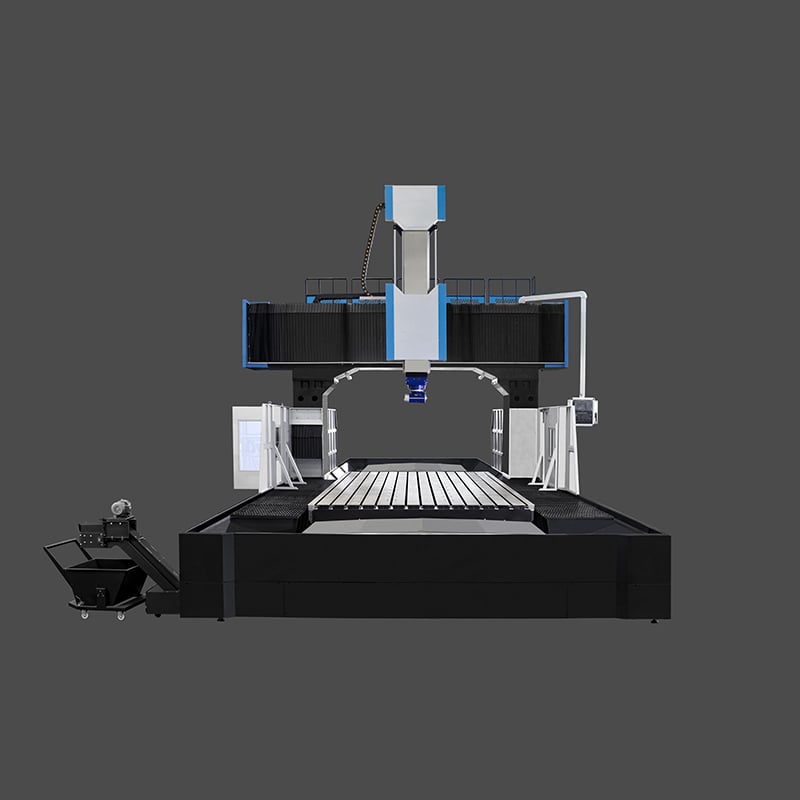

Introducing our Double Column Vertical Machining Center VMC-1160, designed specifically for the needs of the manufacturing industry. With its exceptional product features, including a sturdy double column structure and vertical design, this machine offers unparalleled stability and precision. Perfect for a wide range of applications, it effortlessly handles large-scale machining tasks with ease. Equipped with advanced functions and cutting-edge technology, our VMC-1160 guarantees optimal performance and delivers remarkable results. Gain a competitive edge with this exceptional machine that offers superior accuracy, efficiency, and reliability.

| Item Model | Unit | VMC-6540L | VMC-850L | VMC-855L | VMC-1160L |

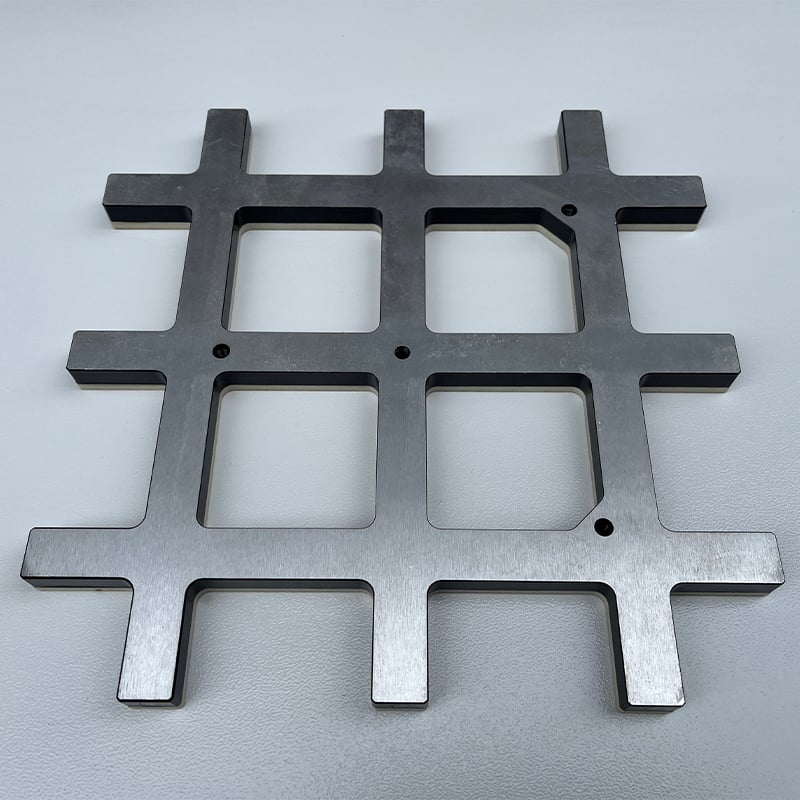

| Worktable | mm | 800×400 | 1000×500 | 1000×500 | 1200×600 |

| Travel for X/Y/Z axes | mm | 650/400/500 | 800/500/500 | 800/550/550 | 1100/600/600 |

| Distance from Spindle nose to table surface | mm | 100-600 | 100-600 | 150-700 | 120-720 |

| Distance from spindle center to column guide surface | mm | 460 | 570 | 570 | 645 |

| Maximum Load of table | kg | 350 | 500 | 600 | 1000 |

| T-slot (number x width) | mm | 3-14-100 | 5-18-90 | 5-18-90 | 5-18-100 |

| Positioning Accuracy | mm | 0.01/300 | 0.01 | 0.01/300 | 0.012/300 |

| Repeatability | mm | 0.008 | 0.008 | 0.008 | 0.008/300 |

| Max. Spindle speed | rpm | 8000or10000 | 8000or10000 | 8000or10000 | 8000or10000 |

| Spindle specifications (model/installation diameter) | BT40/120 | BT40/140 | BT40/150 | BT40/150 | |

| Ball screw, rolling guide | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | |

| Screw specifications (XYZ) | 3216/3216/3216 | 4016/4016/4016 | 4016/4016/4016 | 4012/4012/4012 | |

| Roller guide (XYZ) | mm | 30/30/30 | 35/35/35 | 35/45/45 | 45/45/45 |

| Spindel Cooling System | Air conditioner | ||||

| Lubrication System | Automatic lubrication (58# rail oil) | ||||

| Cutting Oil System | Ring spray, compressed air | ||||

| Vertical disc magazine(ATC) | pcs | 16T | 24T | 24T | 24T |

| Max.Tool (diameter/length/weight) | 90/300/8kg | 78/300/8kg | 78/300/8kg | 78/300/8kg | |

| Tool exchanging manner | Pneumatic | ||||

| Tool change time | sec | 1.8 | 1.8 | 1.8 | 1.8 |

| CNC | SYNTEC 22MA | FANUC 0i MF Pius(5) | FANUC 0i MF Pius(5) | FANUC 0i MF Pius(5) | |

| Spindle Power | Kw | 5.5/7.5 | βiI 8/12000(7.5/11) | βiI 8/12000(7.5/11) | βiI 12/10000(11/15) |

| Servo motor(XYZ) | Nm | AM11×2+AM18B | βiSc 12/3000×2+βiS 22B/3000 | βiSc 12/3000×2+βiS 22B/3000 | βiS 22/3000×2+βiS 30B/2000 |

| Air pressure | Kg/Cm² | 6 | 6 | 6 | 6 |

| Air source flow | m³/min | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 |

| Machine Power | KVA | 15 | 20 | 20 | 30 |

| Dimensions (width×depth×height) | mm | 2320×1800×2200 | 2300×1800×2300 | 2700×2400×2700 | 3150×2450×2750 |

| Machine weight | kg | 3800 | 5000 | 5500 | 6500 |