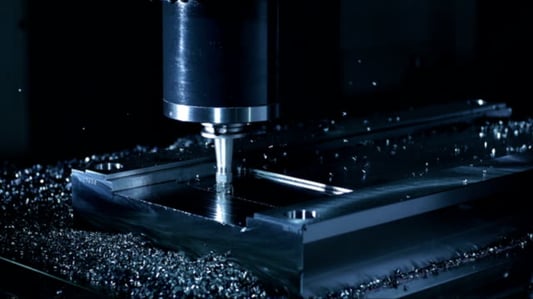

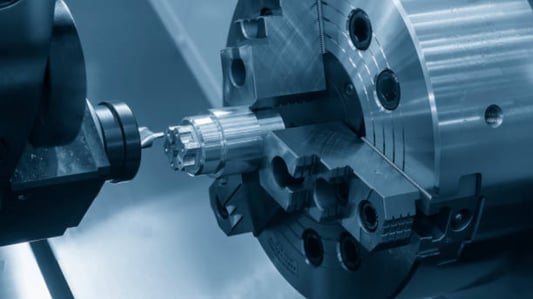

IntroductionIndustrial CNC milling machines have revolutionized the manufacturing industry by providing precise and efficient milling operations. These advanced machines are capable of producing complex parts and components with high accuracy and speed. In this article, we will explore the various aspects of industrial CNC milling machines and their importance in modern manufacturing.The Basics of Industrial CNC Milling MachinesIndustrial CNC milling machines are computer-controlled machines that use rotating cutting tools to remove material from a workpiece. The workpiece is securely held on a table, and the cutting tools, known as milling cutters, move along multiple axes to shape the material. The machines can perform a wide range of operations, including drilling, cutting, and shaping, making them essential in various industries such as automotive, aerospace, and electronics.The Advantages of Industrial CNC Milling MachinesIndustrial CNC milling machines offer numerous advantages over traditional manual milling methods. Firstly, they provide unmatched precision and accuracy, ensuring consistent and high-quality results. The machines can execute complex geometries with ease, enabling the production of intricate parts that were previously impossible to manufacture. Moreover, CNC milling machines are highly efficient, reducing production time and costs.Applications of Industrial CNC Milling MachinesIndustrial CNC milling machines find applications in a wide range of industries. In the automotive industry, these machines are used to manufacture engine components, chassis parts, and prototypes. In the aerospace sector, CNC milling machines are employed to create precise and lightweight parts for aircraft and spacecraft. Additionally, industries such as electronics, medical, and mold-making heavily rely on CNC milling machines for their production needs.Types of Industrial CNC Milling MachinesThere are various types of industrial CNC milling machines available, each designed for specific purposes. Vertical milling machines are the most common type, where the spindle axis is vertically oriented. Horizontal milling machines have a horizontally oriented spindle and are suitable for heavy-duty cutting. Other types include gantry mills, which provide large work areas, and 5-axis milling machines, which offer enhanced flexibility and precision.Factors to Consider when Choosing an Industrial CNC Milling MachineWhen selecting an industrial CNC milling machine, several factors need to be considered. The machine's size and capacity should match the desired workpiece dimensions. The spindle speed and power determine the cutting capabilities, while the number of axes affects the machine's versatility. Additionally, factors such as automation features, software compatibility, and after-sales support should also be taken into account.Maintenance and Safety ConsiderationsMaintaining an industrial CNC milling machine is crucial for its optimal performance and longevity. Regular cleaning, lubrication, and inspection of the machine's components are essential. Additionally, following proper safety protocols is crucial to prevent accidents. Operators should receive training on machine operation, use protective equipment, and adhere to safety guidelines to ensure a safe working environment.The Future of Industrial CNC Milling MachinesThe future of industrial CNC milling machines looks promising. Advancements in technology, such as the integration of artificial intelligence and machine learning, are expected to further enhance the capabilities of these machines. Improved automation and connectivity features will streamline production processes, resulting in increased efficiency and productivity. As industries continue to evolve, industrial CNC milling machines will remain a vital tool for manufacturing.ConclusionIndustrial CNC milling machines have revolutionized manufacturing by offering precise, efficient, and versatile milling capabilities. These machines find applications in various industries and provide numerous advantages over traditional milling methods. As technology advances, the future of industrial CNC milling machines looks promising, with further improvements in precision, automation, and connectivity. Investing in a high-quality industrial CNC milling machine can significantly enhance a company's manufacturing capabilities and competitiveness.Quote InquiryContact us!