High-speed milling is a cutting-edge technology that allows for faster machining processes, resulting in increased efficiency and productivity. By using specialized tools and techniques, high-speed milling operations can achieve higher feed rates and spindle speeds, leading to reduced cycle times and overall cost savings.

Precision and Accuracy in High-Speed Milling

One of the key advantages of high-speed milling is the ability to achieve superior precision and accuracy in the finished parts. With the capability to make more passes in less time, high-speed milling machines can produce complex components with tight tolerances and excellent surface finishes, making them ideal for industries such as aerospace and automotive.

Enhanced Tool Life and Reduced Wear

High-speed milling tools are designed to withstand the rigors of high-speed machining, resulting in longer tool life and reduced wear compared to conventional milling techniques. This means that operators can produce more parts with fewer tool changes, leading to increased uptime and lower maintenance costs.

Versatility and Flexibility of High-Speed Milling

High-speed milling machines are highly versatile and can be used to process a wide range of materials, from aluminum and steel to composites and plastics. This flexibility allows manufacturers to adapt to changing market demands and produce a variety of components with the same machine, saving time and resources.

Improved Chip Evacuation and Heat Dissipation

The high feed rates and spindle speeds used in high-speed milling result in better chip evacuation and heat dissipation, which helps prevent chip buildup and thermal damage to the workpiece. This is especially important when working with heat-sensitive materials or when producing intricate parts with fine details.

Cost-Effective Production with High-Speed Milling

While high-speed milling machines may require a higher initial investment, the long-term cost savings and production benefits outweigh the upfront costs. By reducing cycle times, minimizing tool wear, and optimizing machining processes, manufacturers can achieve higher throughput and profitability with high-speed milling.

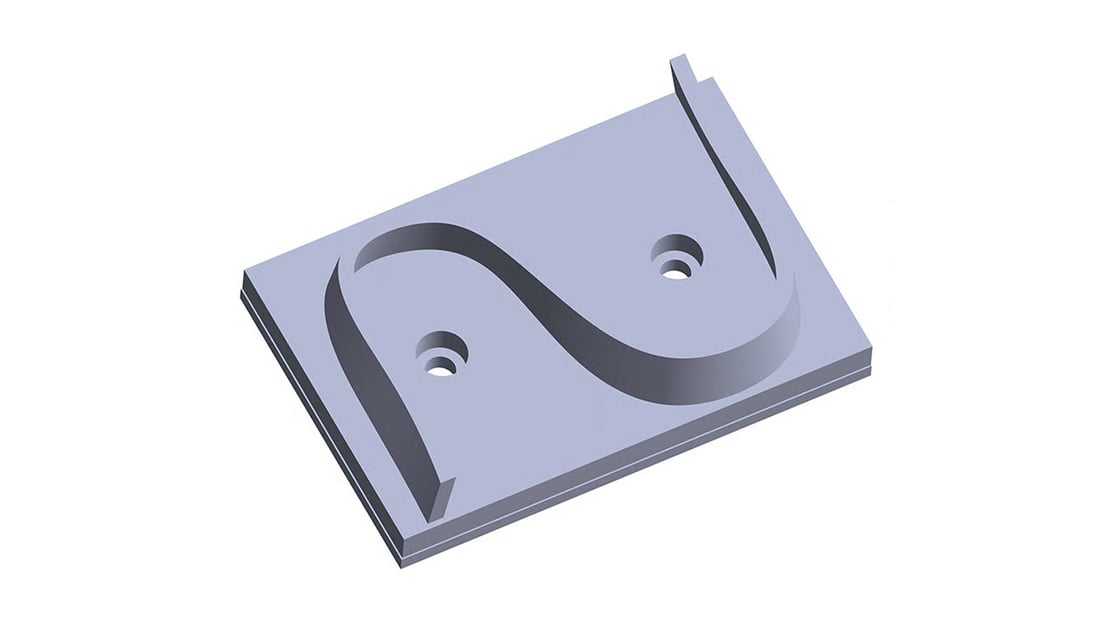

Complex Geometry and 3D Machining Capabilities

High-speed milling techniques excel at handling complex geometry and 3D machining tasks that require precise and intricate features. With advanced software controls and multi-axis machining capabilities, high-speed milling machines can produce complex parts with ease, making them essential tools for modern manufacturing.

Environmental Benefits of High-Speed Milling

High-speed milling processes generate less heat and produce less waste compared to traditional milling methods, making them more environmentally friendly. By reducing energy consumption, material waste, and cutting fluid usage, high-speed milling contributes to sustainable and eco-friendly manufacturing practices.

High-Speed Milling in the Digital Era

As technology continues to advance, high-speed milling machines are becoming more integrated with digital systems and automation tools, enabling seamless communication and real-time data exchange. This digitalization of high-speed milling operations leads to improved efficiency, quality control, and overall productivity.

Future Trends and Innovations in High-Speed Milling

The future of high-speed milling holds exciting possibilities, with ongoing research and development focusing on faster speeds, improved tooling materials, and advanced machining strategies. By staying at the forefront of innovation, manufacturers can harness the full potential of high-speed milling for enhanced competitiveness and performance.

Quote Inquiry

contact us