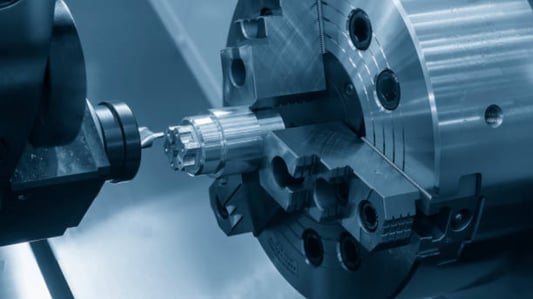

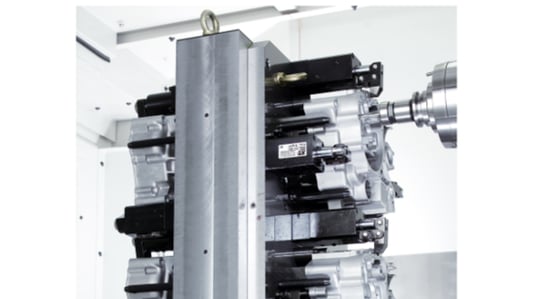

Choosing the Right CNC Milling Manufacturers: A Comprehensive GuideWhen it comes to precision and accuracy in manufacturing, CNC milling plays a crucial role. CNC (Computer Numerical Control) milling is a highly popular manufacturing process that utilizes computerized controls to operate and manipulate machine tools. In this article, we will explore the world of CNC milling manufacturers and provide you with valuable insights to help you make an informed decision when selecting the right manufacturer for your needs.1. Understanding CNC MillingCNC milling is a subtractive manufacturing process that involves the use of computer-controlled machines to remove material from a workpiece. The machine tools used in CNC milling operations can move and rotate on multiple axes to create complex and precise shapes. This technology allows for the production of intricate parts and components with high levels of accuracy and repeatability.2. The Advantages of CNC MillingCNC milling offers several advantages over conventional machining methods. Firstly, it allows for increased automation, reducing the need for manual labor and improving production efficiency. Additionally, CNC milling enables the production of complex geometries that would be difficult or impossible to achieve using traditional methods. The level of precision and accuracy achieved with CNC milling is unparalleled, making it ideal for industries such as aerospace, automotive, and medical.3. Factors to Consider when Choosing CNC Milling ManufacturersWhen selecting a CNC milling manufacturer, there are several crucial factors to consider:Experience and Expertise: Look for manufacturers with a proven track record and extensive experience in CNC milling. Consider their expertise in your specific industry or application.Quality Control: Ensure that the manufacturer has robust quality control processes in place to guarantee the highest level of precision and accuracy in their products.Technological Capabilities: Evaluate the manufacturer's CNC milling machines, tools, and software to ensure they have the latest technology and equipment to meet your requirements.Flexibility and Customization: Determine if the manufacturer can accommodate your specific needs and provide customized solutions if necessary.Cost and Lead Time: Compare prices and lead times among different manufacturers to find the most cost-effective and efficient option for your project.4. Top CNC Milling Manufacturers WorldwideWith numerous CNC milling manufacturers operating globally, it can be challenging to identify the best ones. However, here are some renowned CNC milling manufacturers known for their quality and reliability:Haas Automation: Haas Automation is one of the largest CNC machine tool builders in the world, offering a wide range of CNC milling machines and accessories.DMG Mori: DMG Mori is a global leader in CNC machine tools, providing advanced milling solutions for various industries.Makino: Makino specializes in high-speed CNC milling machines and offers innovative solutions for precision machining.Okuma: Okuma manufactures CNC milling machines known for their robustness and reliability, suitable for various applications.GF Machining Solutions: GF Machining Solutions offers a comprehensive range of CNC milling machines and services, catering to diverse industries.5. The Benefits of Working with CNC Milling ManufacturersCollaborating with CNC milling manufacturers brings numerous benefits to your business:Expertise and Knowledge: CNC milling manufacturers possess extensive expertise and knowledge in their field, ensuring the highest quality and precision in their products.Cost Savings: By outsourcing your CNC milling needs to specialized manufacturers, you can reduce costs associated with machinery, maintenance, and labor.Time Efficiency: CNC milling manufacturers have streamlined processes and advanced machinery that enable faster production and delivery times.Custom Solutions: Manufacturers can offer customized solutions tailored to your specific requirements, ensuring optimal performance and functionality.Quality Assurance: Reputable CNC milling manufacturers have stringent quality control measures in place to ensure the highest quality and accuracy in their products.6. The Future of CNC Milling ManufacturersThe CNC milling industry continues to evolve, driven by technological advancements and increasing demand for precision manufacturing. Some of the upcoming trends in CNC milling include:Automation and Robotics: The integration of automation and robotics into CNC milling processes will enhance efficiency, productivity, and reduce manual labor.Advanced Software and Simulation: The development of sophisticated software and simulation tools will enable even more precise and accurate milling operations.Multi-Axis Machining: CNC milling machines with multiple axes will become more prevalent, allowing for the production of complex and intricate components.Integration of IoT and AI: The Internet of Things (IoT) and Artificial Intelligence (AI) will play a significant role in optimizing CNC milling processes, improving predictive maintenance, and enhancing overall performance.7. ConclusionCNC milling manufacturers play a crucial role in the world of precision manufacturing. By understanding the fundamentals of CNC milling, considering key factors when selecting a manufacturer, and leveraging the benefits they offer, you can ensure the success of your projects. Stay updated with the latest trends and advancements in CNC milling to stay ahead in an ever-evolving industry.Quote InquiryContact us!