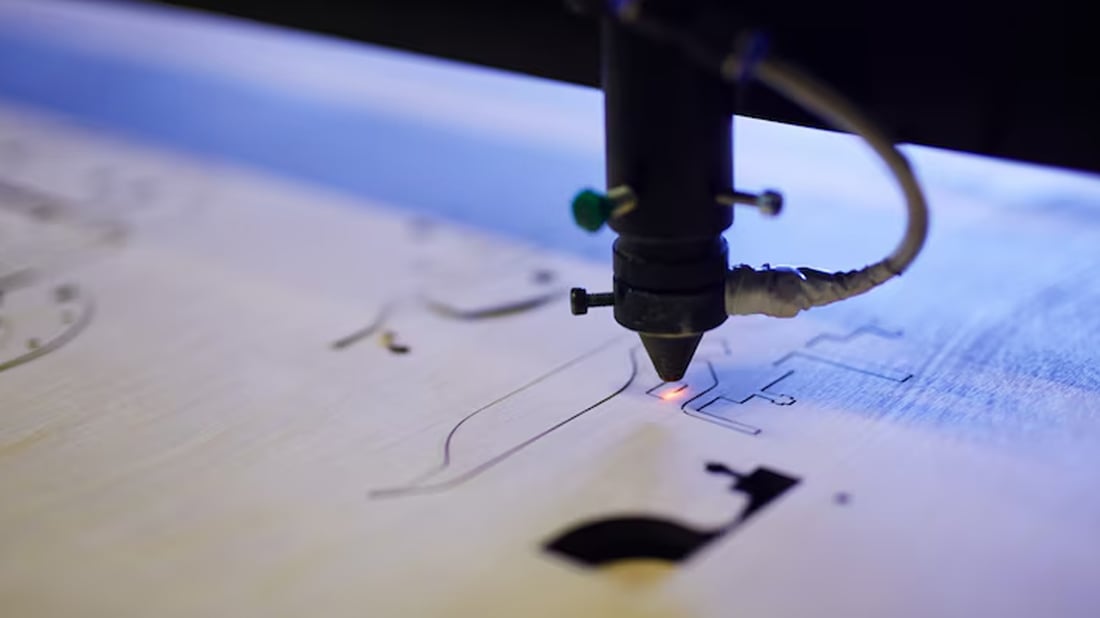

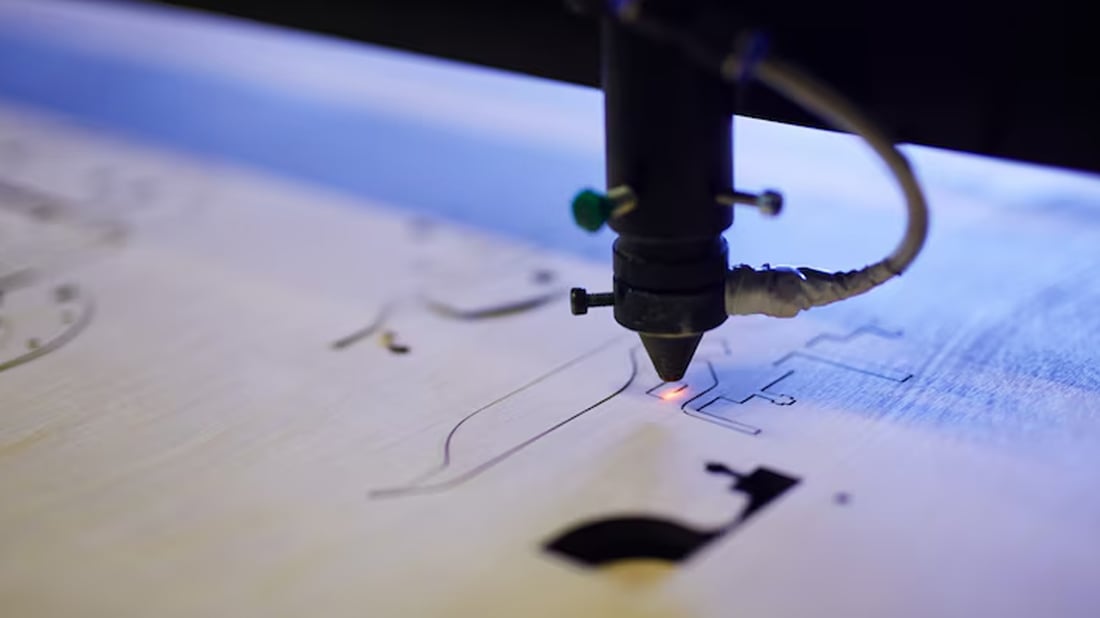

Fiber laser pipe cutting machines are advanced equipment used for precision cutting of various types of pipes and tubes. These machines use a high-powered laser beam to accurately cut through materials such as metal, plastic, and even composite materials. They are widely used in industries like automotive, aerospace, construction, and more for their efficiency and precision in cutting.

Benefits of Using Fiber Laser Pipe Cutting Machines

One of the main advantages of using fiber laser pipe cutting machines is their high cutting speeds and accuracy. These machines can cut through different types of materials with ease, producing clean and precise cuts every time. Additionally, they require minimal maintenance and are known for their energy efficiency, making them a cost-effective solution for industrial cutting operations.

How Fiber Laser Pipe Cutting Machines Work

Fiber laser pipe cutting machines work by focusing a high-powered laser beam onto the surface of the material being cut. The laser beam melts or vaporizes the material, creating a clean and smooth cut. These machines are equipped with computer-controlled systems that allow for precise cutting of materials in various shapes and sizes. The cutting process is fast and efficient, making fiber laser pipe cutting machines ideal for high-volume production.

Applications of Fiber Laser Pipe Cutting Machines

Fiber laser pipe cutting machines have a wide range of applications in various industries. They are commonly used for cutting pipes and tubes for manufacturing components such as exhaust systems, hydraulic systems, and structural components. These machines are also used in the production of furniture, signage, and other metal fabrication applications where precision cutting is essential.

Features to Consider When Choosing a Fiber Laser Pipe Cutting Machine

When selecting a fiber laser pipe cutting machine, it is important to consider various features to ensure you are getting the right equipment for your cutting needs. Some key features to look for include laser power, cutting speed, cutting thickness capacity, software capabilities, and automation options. It is also important to consider the size and shape of the pipes you will be cutting to choose a machine that meets your specific requirements.

Maintenance and Safety Tips for Fiber Laser Pipe Cutting Machines

To ensure optimal performance and longevity of your fiber laser pipe cutting machine, regular maintenance is essential. This includes keeping the machine clean, checking and replacing worn parts, and calibrating the machine as needed. It is also important to follow safety guidelines when operating the machine to prevent accidents and injuries.

Advancements in Fiber Laser Pipe Cutting Technology

In recent years, there have been significant advancements in fiber laser pipe cutting technology, leading to improved cutting speeds, precision, and efficiency. New innovations in software integration, automation, and laser technology have made fiber laser pipe cutting machines more versatile and user-friendly. These advancements have expanded the capabilities of these machines, making them even more essential in modern industrial cutting operations.

Choosing the Right Fiber Laser Pipe Cutting Machine for Your Business

When choosing a fiber laser pipe cutting machine for your business, it is important to consider your specific cutting needs, budget, and production requirements. It is recommended to consult with a reputable supplier or manufacturer to determine the best machine for your application. Investing in a high-quality fiber laser pipe cutting machine can help improve the efficiency and quality of your cutting processes, ultimately leading to increased productivity and profitability.

The Future of Fiber Laser Pipe Cutting Machines

As technology continues to advance, the future of fiber laser pipe cutting machines looks promising. With ongoing innovations in laser technology, automation, and software integration, these machines are expected to become even more efficient, precise, and versatile. The demand for fiber laser pipe cutting machines is likely to increase as industries seek faster and more accurate cutting solutions for their production processes.

Quote Inquiry

contact us