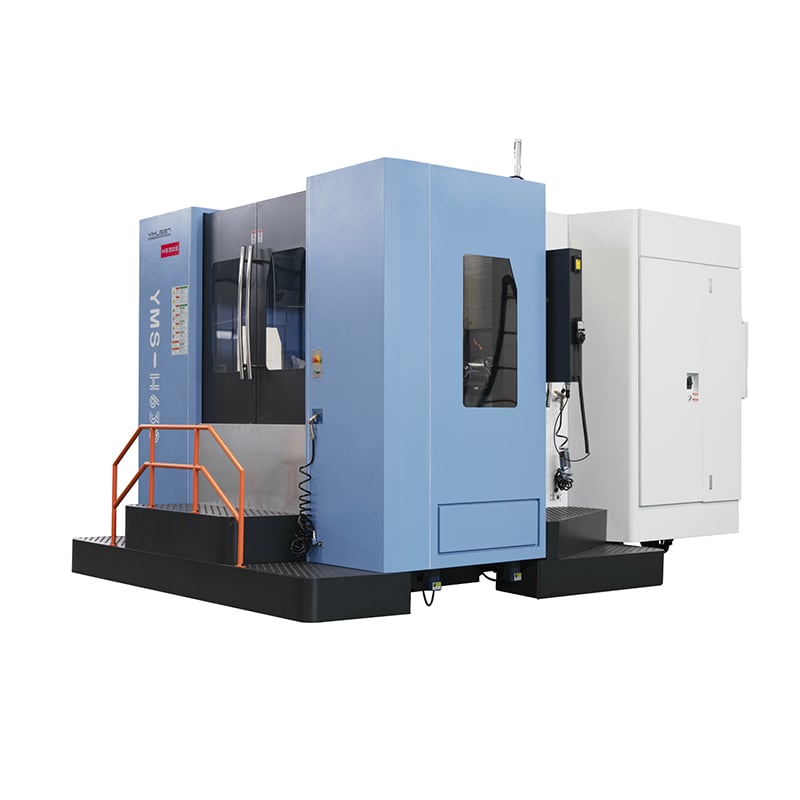

Introducing the YMSH63S 4 axis horizontal machining center, designed specifically for the manufacturing of CNC machinery. This state-of-the-art machine offers impeccable precision and efficiency, thanks to its 4-axis capability. It enables users to effortlessly perform complex machining tasks with utmost accuracy. Whether it's milling, drilling, or tapping, this machining center excels in every operation. With its robust construction and advanced technology, it guarantees superior performance and durability. Stay ahead of the competition with the YMSH63S and experience unmatched productivity and cost-effectiveness.

| 机型项目 Machine Type | 单位Unit | YMSH50S | YMSH63S | YMSH80S | YMSH100S |

| 工作台Worktable | |||||

| 工作台尺寸Worktable | mm | 500×500 | 630×630 | 800×800 | 1000×1000 |

| 工作台最大负重Maximun Load of table | kg | 800 | 1200 | 2000 | 3000 |

| 工作台T型槽T-slot (number x width) | mm | 5-18-100 | 5-18-125 | 5-22-160 | 7-22-125 |

| 定位精度Positioning Accuracy | sec | 10 | 10 | 10 | 10 |

| 重复定位精度Repeatability | sec | 2 | 2 | 2 | 2 |

| 加工范围Processing range | |||||

| X/Y/Z轴行程Travel for X/Y/Z axes | mm | 700/600/580 | 1000/770/900 | 1300/1000/1000 | 1600/1100/1100 |

| 主轴端面至工作台中心距离Distance form Spindle nose to table surface | mm | 225-1125 | 175-1075 | 200-1200 | 200-1200 |

| 主轴中心线至工作台面距离Distance from spindle center to table surface | mm | 110-880 | 110-880 | 150-1150 | 150-1150 |

| 主轴Spindle | |||||

| 主轴规格Spindle specifications | BT50 | BT50 | BT50 | BT50 | |

| 主轴最高转速Max. Spindle speed | rpm | 6000 | 6000 | 6000 | 6000 |

| 主轴电机功率Spindle Mootor Power | Kw | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 |

| 驱动进给Drive feed | |||||

| 快速进给速度(X/Y/Z)Fast feed speed | m/min | 24/20/24 | 24/20/24 | 24/20/20 | 24/20/20 |

| 快速进给速度(B)Fast feed speed(B) | r/min | 10 | 10 | 10 | 10 |

| 刀库Tool magazine | |||||

| 圆盘式刀库Vertical disc magazine(ATC) | pcs | 24T | 24T | 24T | 24T |

| 平均换刀时间Tool change time | sec | 4.01 | 4.01 | 4.01 | 4.01 |

| 最大刀具重量Max.Tool weight | kg | 18 | 18 | 18 | 18 |

| 最大刀具直径(满刀)Max.Tool dia(fully loaded) | mm | 112 | 112 | 112 | 112 |

| 最大刀具直径(临空刀)Max.Tool dia(no adjacent) | mm | 200 | 200 | 200 | 200 |

| 最大刀具长度Max.Tool length | mm | 300 | 300 | 300 | 300 |

| 刀具交换方式Tool exchanging manner | Pneumatic/random | ||||

| 精度Precision | |||||

| 定位精度(X/Y/Z)Positioning Accuracy | mm | 0.01 | 0.01 | 0.012 | 0.012 |

| 重复定位精度(X/Y/Z)Repeatability | mm | 0.006 | 0.006 | 0.008 | 0.008 |

| 气源Air supply | |||||

| 空气压力Air pressure | Kg/Cm² | 6-8 | 6-8 | 6-8 | 6-8 |

| 气源流量Air source flow | m³/min | 280 | 280 | 280 | 280 |

| 其它Other | |||||

| 机械重量Machine weight | kg | 12500 | 13000 | 18000 | 18500 |

| 电力消耗Machine Power | KVA | 35 | 35 | 45 | 45 |

| 外形尺寸Dimensions (width×depth×height) | mm | 4720×3430×3350 | 4720×3430×3350 | 5210×4125×3700 | 5210×4125×3700 |

| 滚珠丝杠,滚动导轨Ball screw, rolling guide | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | Taiwan HIWIN/PMI | |

| 丝杠规格(XYZ)Screw specifications (XYZ) | 3216/3216/3216 | 4016/4016/4016 | 4016/4016/4016 | 4012/4012/4012 | |

| 滚柱导轨(XYZ)Roller guide (XYZ) | mm | 55/55/55 | 55/55/55 | 55/55/55 | 55/55/55 |

| 主轴冷却系统Spindel Cooling System | Air conditioner | ||||

| 润滑系统Lubrication System | Automatic lubrication (68# rail oil) | ||||

| 切削冷却系统Cutting Oil System | Ring spray, compressed air | ||||

| 控制器系统CNC | FANUC 0i MF Pius(5) | FANUC 0i MF Pius(5) | FANUC 0i MF Pius(5) | FANUC 0i MF Pius(5) | |