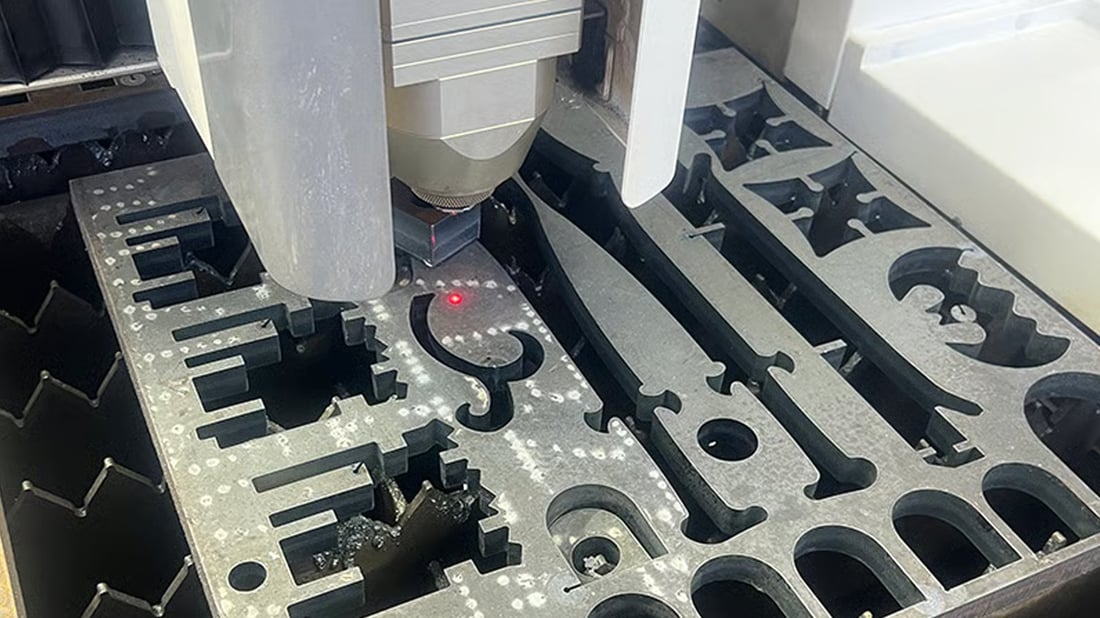

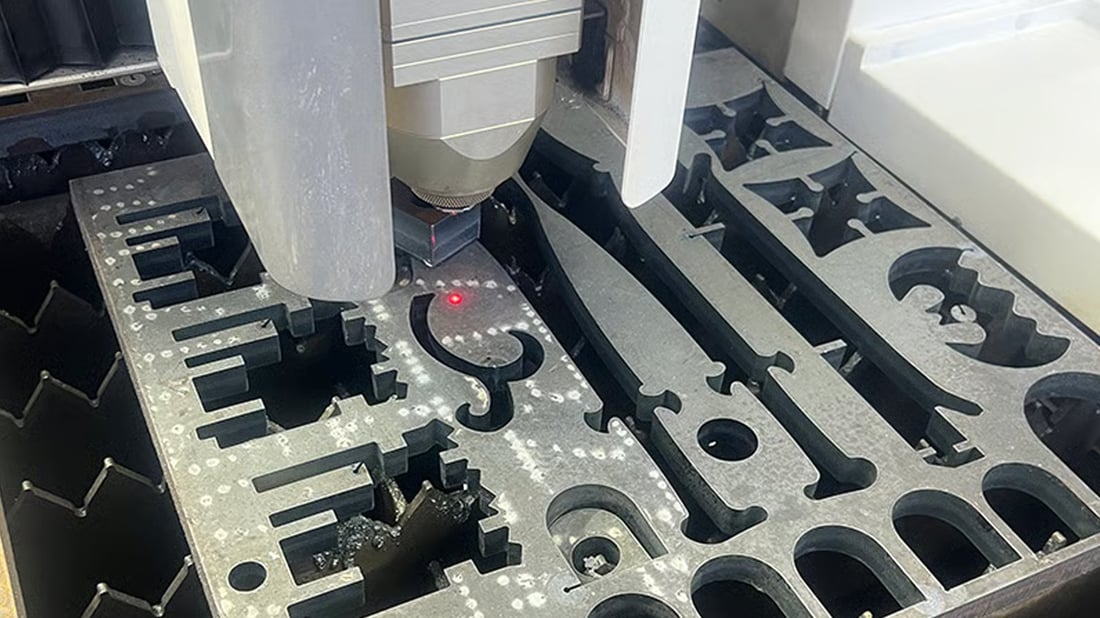

Metal sheet laser cutting is a high-precision method of cutting various types of metals with the help of a laser beam. This process uses a focused and high-powered laser beam to melt, vaporize, or blow away material, leaving a high-quality surface finish. It is widely used in industries such as automotive, aerospace, and manufacturing for its accuracy and efficiency.

The Advantages of Metal Sheet Laser Cutting

One of the main advantages of metal sheet laser cutting is its ability to create intricate and detailed designs with minimal waste. The process is also faster and more precise than traditional cutting methods, making it cost-effective for large-scale production. Additionally, laser cutting produces clean edges without the need for secondary finishing processes.

The Types of Metals Suitable for Laser Cutting

Metal sheet laser cutting can be used on a variety of metals, including stainless steel, aluminum, copper, and brass. Each metal has different properties that affect the cutting process, such as conductivity and reflectivity. It is essential to choose the right type of laser and cutting parameters for the specific metal being used to achieve optimal results.

The Importance of Laser Cutting Parameters

Laser cutting parameters such as power, speed, and focus are crucial in determining the quality and efficiency of the cutting process. The proper selection of these parameters can result in smooth cuts, minimal heat-affected zones, and reduced material waste. Testing and adjusting these parameters are essential to achieve the desired outcome.

The Applications of Metal Sheet Laser Cutting

Metal sheet laser cutting is used in various industries for a wide range of applications, including cutting flat sheets for fabrication, creating prototypes, and producing intricate designs for architectural and decorative purposes. It is also used in automotive manufacturing for cutting components with high precision and consistency.

The Impact of Laser Technology on Metal Fabrication

The advancements in laser technology have revolutionized the metal fabrication industry, making it possible to cut complex shapes and designs with incredible accuracy. Laser cutting has replaced traditional methods such as plasma cutting and mechanical cutting due to its superior precision and efficiency. It has also led to increased automation and productivity in metal fabrication processes.

The Future of Metal Sheet Laser Cutting

With ongoing advancements in laser technology and automation, the future of metal sheet laser cutting looks promising. Innovations such as fiber lasers, robotic arms, and real-time monitoring systems are improving the efficiency and accuracy of the cutting process. As demand for customization and fast turnaround times increases, laser cutting will continue to play a vital role in metal fabrication.

The Environmental Benefits of Laser Cutting

Metal sheet laser cutting is considered a more environmentally friendly process compared to traditional cutting methods because it produces less waste and reduces the need for harmful chemicals. The precision of laser cutting also results in minimal material loss, leading to cost savings and a smaller carbon footprint. Additionally, the energy efficiency of laser cutting equipment contributes to sustainable manufacturing practices.

The Cost Considerations of Metal Sheet Laser Cutting

While metal sheet laser cutting offers many benefits, including high precision and efficiency, there are cost considerations to take into account. Factors such as machine setup, maintenance, and operational costs can impact the overall cost of laser cutting services. It is essential for businesses to evaluate these costs against the quality and speed advantages of laser cutting to make informed decisions.

The Importance of Choosing a Reliable Laser Cutting Service

When outsourcing metal sheet laser cutting services, it is crucial to choose a reliable and experienced provider. Look for a company with state-of-the-art equipment, knowledgeable staff, and a track record of delivering high-quality results. By partnering with a reputable laser cutting service, you can ensure a seamless production process and achieve superior finished products.

Quote Inquiry

contact us