CO2 laser cutting is a technology that uses a high-powered laser to cut through materials. The laser beam is generated by exciting a mixture of gases that include carbon dioxide, nitrogen, and helium. This process produces a highly focused beam of infrared light that is incredibly powerful and precise.

Benefits of CO2 Laser Cutting

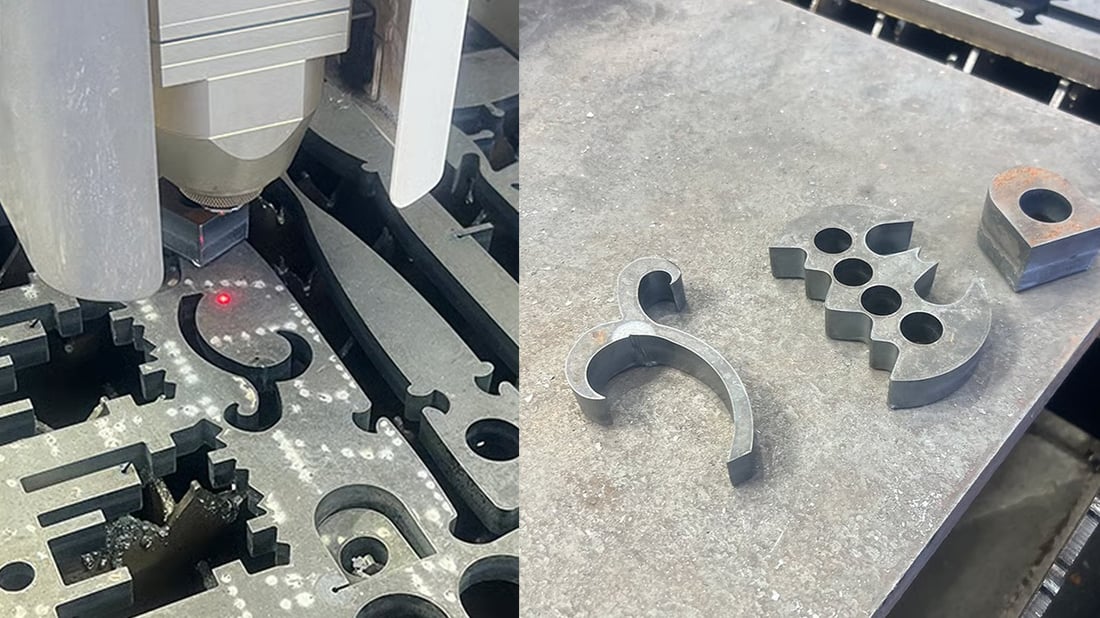

There are numerous benefits to using CO2 laser cutting. This method is extremely precise, allowing for intricate designs and precise cuts. It is also a fast process, making it ideal for high-volume production. Additionally, CO2 laser cutting produces clean cuts without the need for additional finishing processes.

Materials Suitable for CO2 Laser Cutting

CO2 laser cutting is versatile and can be used on a wide range of materials. Some common materials that are suitable for CO2 laser cutting include acrylic, wood, plastic, fabric, and paper. It is important to note that different materials may require adjustments to the laser settings for optimal results.

Applications of CO2 Laser Cutting

CO2 laser cutting is widely used in various industries for cutting, engraving, and marking. It is commonly used in the manufacturing industry for cutting components such as gaskets, seals, and panels. Additionally, CO2 laser cutting is used in the signage industry for creating intricate designs on materials such as acrylic and metal.

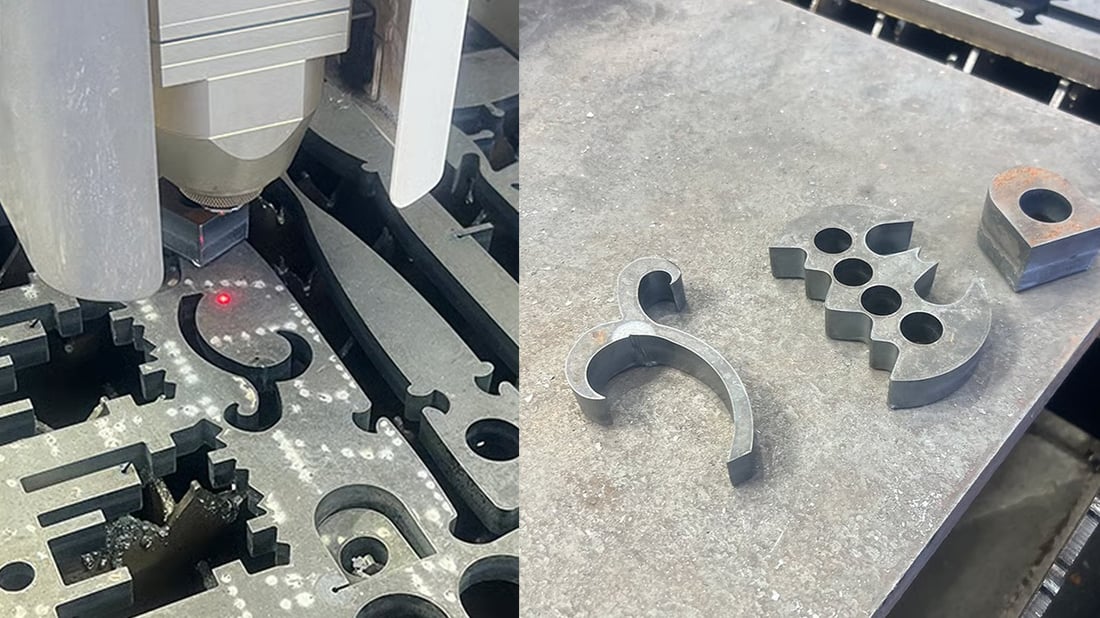

CO2 Laser Cutting Process

The CO2 laser cutting process involves focusing a high-powered laser beam onto the material to be cut. The laser beam melts, burns, or vaporizes the material, creating a clean and precise cut. The process is controlled by a computer system that directs the laser beam according to the desired design.

Advancements in CO2 Laser Cutting Technology

Over the years, there have been significant advancements in CO2 laser cutting technology. These advancements have led to increased cutting speeds, improved precision, and enhanced efficiency. Additionally, new features such as automatic material detection and real-time monitoring have revolutionized the CO2 laser cutting process.

Considerations for CO2 Laser Cutting Machines

When choosing a CO2 laser cutting machine, there are several factors to consider. These include the power of the laser, the size of the cutting bed, the speed of cutting, and the compatibility with different materials. It is important to select a machine that meets the specific requirements of your cutting projects.

CO2 Laser Cutting vs. Other Cutting Methods

CO2 laser cutting offers several advantages over traditional cutting methods such as plasma cutting and water jet cutting. It produces cleaner cuts with minimal heat-affected zones, resulting in less distortion of the material. Additionally, CO2 laser cutting is more environmentally friendly as it does not produce harmful byproducts.

Future Trends in CO2 Laser Cutting

The future of CO2 laser cutting looks promising with ongoing advancements in technology. New developments such as increased automation, improved laser beam quality, and integration with 3D printing are expected to further enhance the capabilities of CO2 laser cutting machines. These trends will continue to drive innovation in the industry.

Choosing the Right CO2 Laser Cutting Service

When outsourcing CO2 laser cutting services, it is important to choose a reputable and experienced provider. Look for a company that offers a wide range of cutting capabilities, utilizes state-of-the-art equipment, and has a track record of delivering high-quality results. By selecting the right service, you can achieve your cutting requirements with precision and efficiency.

Quote Inquiry

contact us