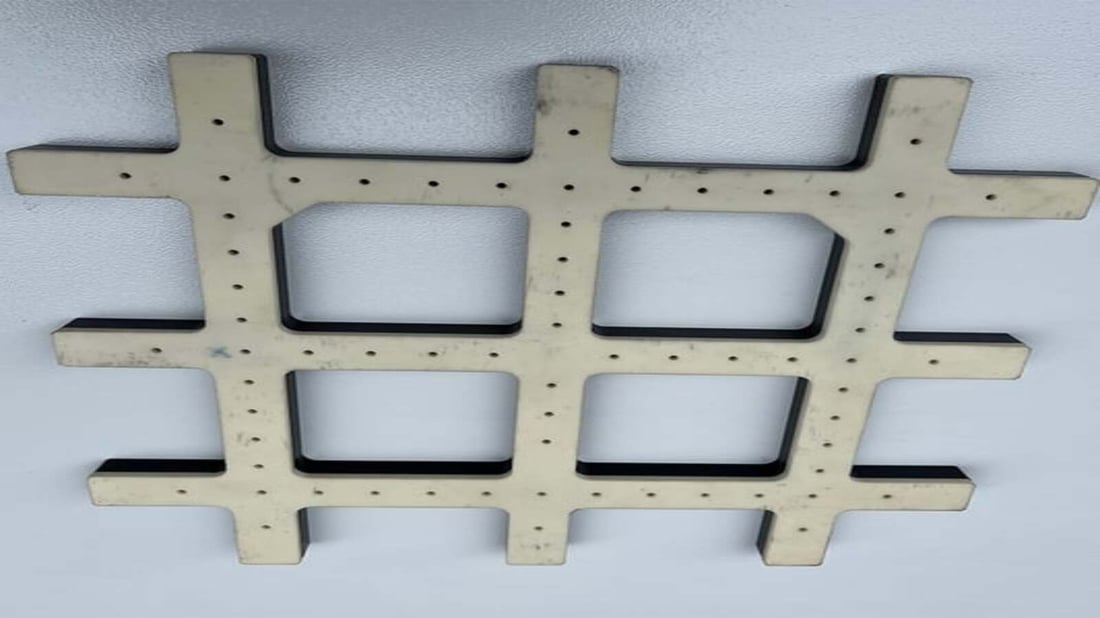

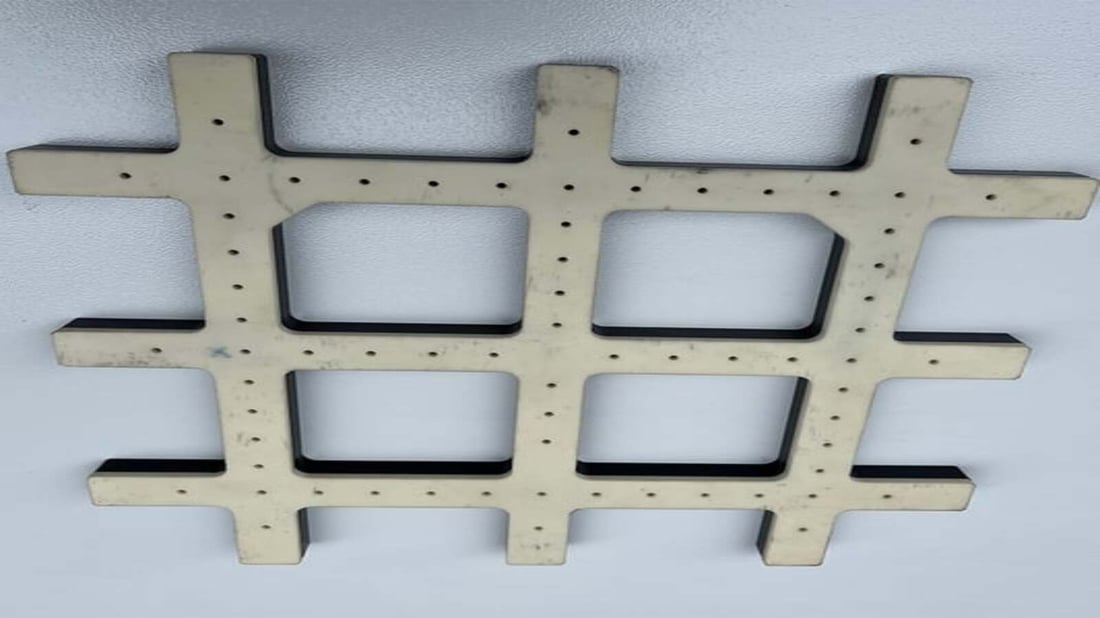

A CNC double column vertical machining center is a type of machine tool equipped with a CNC (Computer Numerical Control) system that is used to automatically control the machining process. This machine is designed for cutting, milling, and shaping various materials such as metal, wood, plastic, and composites. The "double column" design refers to the two columns that support the crossbeam, which provides enhanced stability and precision during heavy-duty machining operations.

Advantages of CNC Double Column Vertical Machining Center

One of the key advantages of a CNC double column vertical machining center is its ability to handle large, heavy workpieces with ease. The double column design contributes to the machine's rigidity, allowing for high cutting speeds and excellent accuracy. Additionally, the vertical orientation of the spindle ensures optimal chip removal and minimizes vibration, resulting in superior surface finishes and extended tool life.

Applications of CNC Double Column Vertical Machining Center

CNC double column vertical machining centers are widely used in various industries such as aerospace, automotive, defense, and mold making. These machines are ideal for producing complex parts and components with tight tolerances. Common applications include machining large molds, dies, engine components, and structural parts for aircraft and vehicles. The versatility and precision of these machines make them indispensable in modern manufacturing processes.

Features of CNC Double Column Vertical Machining Center

The features of a CNC double column vertical machining center may vary depending on the manufacturer and model, but some common features include a powerful spindle motor, multiple-axis control, automatic tool changer, coolant system, and chip conveyor. These machines are equipped with advanced CNC software that enables operators to program complex toolpaths, simulate machining operations, and monitor real-time performance data.

Factors to Consider When Choosing a CNC Double Column Vertical Machining Center

When selecting a CNC double column vertical machining center for your business, it is essential to consider factors such as the machine's size, cutting capacity, spindle speed, tooling options, and control system. The choice of machine will depend on your specific machining requirements, production volume, budget, and available floor space. It is advisable to consult with a reputable machine tool dealer or manufacturer to determine the best fit for your operations.

Advancements in CNC Double Column Vertical Machining Center Technology

In recent years, there have been significant advancements in CNC double column vertical machining center technology, including the integration of IoT (Internet of Things) connectivity, AI (Artificial Intelligence) features, and automation capabilities. These developments have led to increased productivity, efficiency, and flexibility in machining operations. Manufacturers are constantly innovating to meet the evolving demands of the industry and stay competitive in the global market.

Maintenance and Care of CNC Double Column Vertical Machining Center

Proper maintenance and care are essential to ensure the optimal performance and longevity of a CNC double column vertical machining center. Regularly scheduled maintenance, such as cleaning, lubrication, and inspection of critical components, will help prevent breakdowns and prolong the machine's lifespan. It is recommended to follow the manufacturer's guidelines and consult with qualified technicians for any repairs or replacements.

Training and Skill Development for Operating CNC Double Column Vertical Machining Center

Operating a CNC double column vertical machining center requires specialized training and skill development to program the machine, set up workpieces, select cutting tools, and monitor the machining process. Operators need to have a good understanding of CNC programming, machine operation, and safety procedures to operate the machine efficiently and safely. Training programs and courses are available to help individuals acquire the necessary skills and knowledge.

Future Trends in CNC Double Column Vertical Machining Center Industry

The future of CNC double column vertical machining centers is expected to be driven by advancements in automation, AI, robotics, and digitalization. As manufacturing technologies continue to evolve, CNC machines will become more intelligent, interconnected, and autonomous. Industry 4.0 initiatives will further revolutionize the way machining centers are operated, monitored, and optimized for maximum efficiency and productivity.

Conclusion

In conclusion, a CNC double column vertical machining center is a versatile and powerful machine tool that plays a crucial role in modern manufacturing processes. With its superior precision, efficiency, and reliability, this machine is a valuable asset for industries that require high-performance machining solutions. By understanding the key features, applications, and advancements in CNC double column vertical machining center technology, businesses can enhance their productivity, competitiveness, and profitability in today's dynamic market landscape.

Quote Inquiry

Contact us