Increased Efficiency in Small Workspace

small vertical machining centers are designed to maximize efficiency in a limited workspace. These compact machines are ideal for small workshops or factories where space is a premium. With their vertical design, these machining centers can fit into tight spaces without compromising on performance.

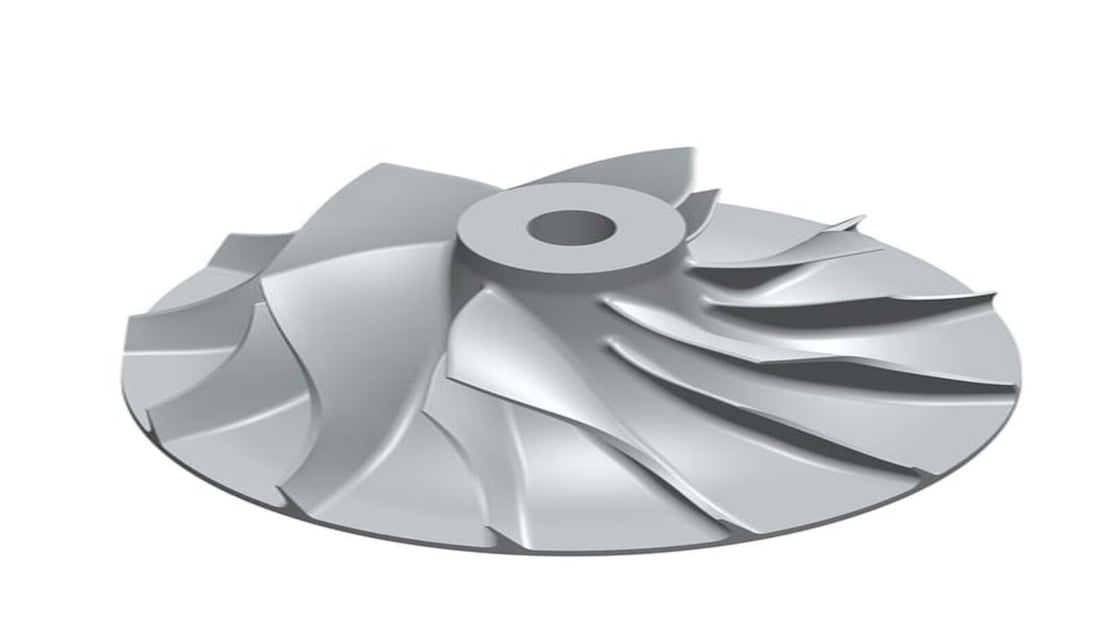

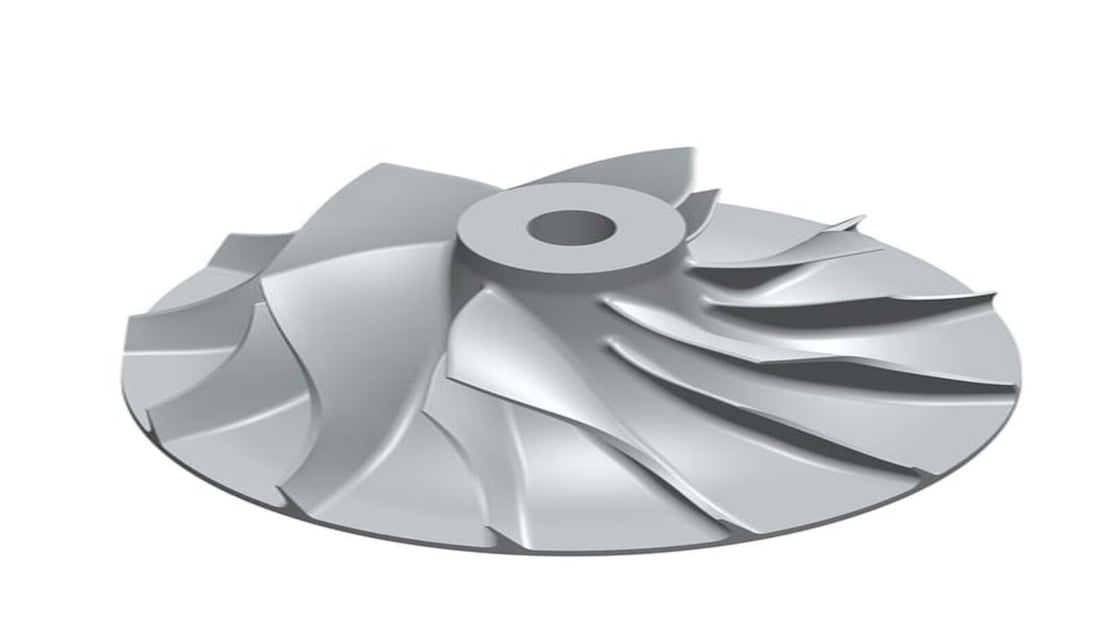

Precision Machining Capabilities

Small vertical machining centers offer high precision machining capabilities, allowing for intricate and detailed work to be done with ease. These machines are equipped with advanced technologies and features that ensure accuracy and consistency in every operation.

Cost-Effective Solution for Small Businesses

For small businesses looking to invest in machining technology, a small vertical machining center is a cost-effective solution. These machines are affordable compared to larger, more complex machining centers, making them an attractive option for businesses with budget constraints.

Versatility in Machining Options

Despite their compact size, small vertical machining centers offer a wide range of machining options. From drilling and milling to tapping and boring, these machines can handle various machining operations with precision and efficiency. This versatility makes them suitable for a diverse range of applications.

Enhanced Productivity and Workflow

By investing in a small vertical machining center, businesses can enhance productivity and workflow. These machines are designed to streamline the machining process, reducing downtime and increasing output. With faster cycle times and improved efficiency, businesses can achieve higher productivity levels.

Space-Saving Design for Optimal Use of Space

Small vertical machining centers are specifically designed to optimize space utilization. Their vertical configuration allows for a smaller footprint, leaving more floor space available for other equipment or operations. This space-saving design is especially beneficial for small workshops or factories with limited space.

Easy Integration with Automation Systems

Small vertical machining centers can be easily integrated with automation systems, allowing for unmanned operations and increased productivity. By connecting these machines to a robotic arm or conveyor system, businesses can streamline their workflow and reduce manual labor requirements.

High-Speed Machining for Quick Turnaround

Small vertical machining centers are capable of high-speed machining, enabling quick turnaround times for production runs. With faster spindle speeds and rapid tool changes, these machines can efficiently produce parts and components in a fraction of the time compared to manual machining processes.

Improved Tool Life and Durability

Thanks to their advanced technologies and precision engineering, small vertical machining centers offer improved tool life and durability. These machines are built to withstand heavy-duty machining operations, ensuring long-term reliability and performance. With proper maintenance, the tools and components of these machines can last for a long time.

Enhanced Quality Control and Consistency

Small vertical machining centers provide enhanced quality control and consistency in machining operations. With their precise measurements and cutting-edge features, these machines can produce parts and components with tight tolerances and minimal variation. This level of quality assurance is essential for businesses operating in industries where accuracy is paramount.

Quote Inquiry

Contact us