An Introduction to Milling Process in CNC Machines

The milling process is a crucial step in modern manufacturing, allowing for the creation of complex and precise parts. In this article, we will explore the milling process in CNC machines, discussing its various aspects and applications.

Understanding CNC Machines

CNC stands for Computer Numerical Control. CNC machines are advanced tools that use computer programs to control their movements and operations. These machines are widely used in various industries, including automotive, aerospace, and electronics, due to their ability to produce intricate parts with high precision.

What is Milling?

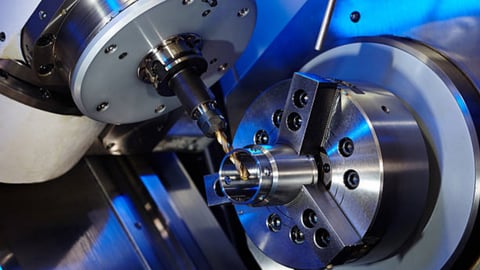

Milling is a subtractive manufacturing process that involves removing material from a workpiece using rotary cutters. The milling process can be performed on a variety of materials, including metal, plastic, and wood. It is commonly used to create complex shapes, slots, holes, and other features.

Types of Milling Machines

There are several types of milling machines, each designed for specific applications. Some common types include:

- Vertical milling machines: These machines have a vertical spindle and are commonly used for face milling, end milling, and drilling operations.

- Horizontal milling machines: These machines have a horizontal spindle and are suitable for heavy-duty milling operations.

- Bed type milling machines: These machines have a fixed bed and are known for their stability and rigidity.

- Bridgeport milling machines: These machines are versatile and widely used in small to medium-sized workshops.

The CNC Milling Process

The CNC milling process involves several steps, including:

- Designing the part: The first step in the milling process is to design the part using CAD (Computer-Aided Design) software. This software allows engineers to create a virtual model of the part, specifying its dimensions and features.

- Programming the machine: Once the part is designed, the next step is to program the CNC machine. This involves creating a sequence of instructions that the machine will follow to produce the desired part.

- Setting up the machine: Before starting the milling process, the machine needs to be properly set up. This includes installing the appropriate tools, securing the workpiece, and adjusting the machine settings.

- Executing the milling process: Once everything is set up, the CNC machine starts the milling process. The machine moves the cutting tool along various axes, removing material from the workpiece to create the desired shape and features.

- Monitoring and quality control: Throughout the milling process, operators monitor the machine's performance and ensure the quality of the produced parts. They may make adjustments to the machine settings or tools if necessary.

- Finishing and post-processing: After the milling process is complete, the parts may undergo additional finishing and post-processing steps, such as deburring, polishing, or coating, to achieve the desired surface finish and functionality.

Advantages of CNC Milling

The CNC milling process offers several advantages over traditional manual milling:

- Precision: CNC machines can achieve high levels of precision, ensuring the accuracy of the produced parts.

- Efficiency: CNC machines can operate continuously, allowing for faster production rates and increased efficiency.

- Capability for complex shapes: CNC machines can create intricate and complex shapes that would be challenging or impossible to achieve manually.

- Repeatability: CNC machines can repeat the same milling process multiple times, ensuring consistent results.

- Automation: CNC machines can be fully automated, reducing the need for manual intervention and increasing productivity.

Applications of CNC Milling

CNC milling is used in a wide range of industries and applications:

- Automotive: CNC milling is used to manufacture various automotive components, such as engine parts, transmission components, and brake system parts.

- Aerospace: CNC milling is crucial in the aerospace industry for producing complex parts with tight tolerances, such as turbine blades and aircraft structural components.

- Electronics: CNC milling is used for manufacturing printed circuit boards (PCBs), electronic enclosures, and other electronic components.

- Medical: CNC milling is utilized in the medical field for producing medical implants, prosthetics, and surgical instruments.

- Furniture and woodworking: CNC milling is employed to create intricate designs and shapes in furniture and woodworking applications.

Conclusion

The milling process in CNC machines is a versatile and precise method for manufacturing complex parts. With the ability to produce intricate shapes and achieve high levels of precision, CNC milling has revolutionized modern manufacturing across various industries. Whether in automotive, aerospace, electronics, or other fields, CNC milling plays a crucial role in creating the components and products that power our world.