The Distinction Between CNC Machines and CNC Mills Explained

Introduction:

When it comes to modern manufacturing processes, computer numerical control (CNC) technology has revolutionized the way products are created. CNC machines and CNC mills are two terms that are often used interchangeably, but they are not exactly the same. In this article, we will explore the differences between CNC machines and CNC mills, shedding light on their unique features, functions, and applications.

1. Understanding CNC Machines

CNC machines, short for computer numerical control machines, encompass a wide range of automated devices utilized in various industries. These machines are capable of executing precise tasks based on programmed instructions. They are commonly used for cutting, shaping, drilling, and milling materials such as metal, wood, plastic, and composites. CNC machines are versatile and can be found in sectors like aerospace, automotive, electronics, and more.

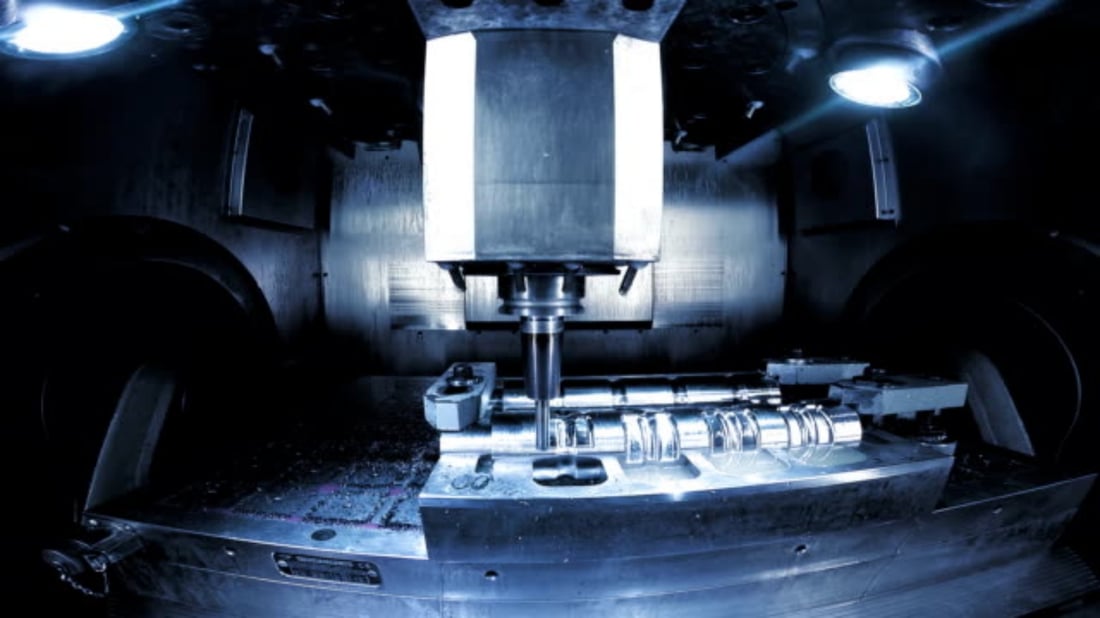

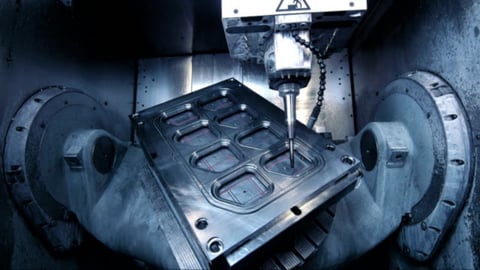

2. The Basics of CNC Mills

CNC mills, on the other hand, are a specific type of CNC machine that focuses primarily on milling operations. Milling is a machining process that involves removing material from a workpiece using rotary cutters. CNC mills are equipped with rotating cutting tools that move along multiple axes to shape and create complex parts. These machines are widely used in the manufacturing of components for industries like automotive, aerospace, and mold-making.

3. Key Differences in Functionality

While CNC machines encompass a broader category, CNC mills are a specialized subset with specific functionalities. CNC machines can include various types such as CNC routers, lathes, plasma cutters, and more. Each type serves a different purpose, while CNC mills focus on milling operations exclusively. Understanding this distinction helps clarify the scope of capabilities for each type of machine.

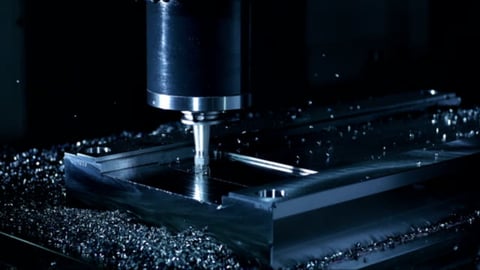

4. Types of Operations of CNC Mills

CNC machines are designed to perform a wide range of operations, including cutting, drilling, shaping, and carving. They can handle materials in different forms, such as sheets, bars, blocks, or even 3D objects. On the other hand, CNC mills are primarily used for milling operations, which involve removing material from a workpiece to create precise shapes, slots, holes, and contours. CNC mills excel at creating complex geometries with high precision.

5. Axis Configuration of CNC Mills

Another key difference lies in the axis configuration of CNC machines and CNC mills. CNC machines can have varying numbers of axes, typically ranging from 3 to 5. The number of axes determines the machine's ability to move and position the cutting tool in different directions. CNC mills, specifically, are commonly equipped with 3 or 4 axes. This axis configuration enables the tools to move along the X, Y, and Z axes, allowing for greater versatility in milling operations.

6. Applications of CNC Machines

Due to their versatility, CNC machines find applications in a wide array of industries. CNC routers are commonly used in woodworking, sign-making, and cabinetry. CNC lathes are used for turning operations in the creation of cylindrical components. CNC plasma cutters are utilized for precise cutting of metal plates, while CNC 3D printers enable the additive manufacturing of intricate designs. The versatility of CNC machines makes them indispensable in modern manufacturing processes.

7. Applications of CNC Mills

CNC mills have specific applications that require precise milling operations. They are extensively used in industries that demand accurate and intricate components, such as automotive, aerospace, and mold-making. CNC mills are capable of manufacturing complex parts with high precision, making them invaluable in the production of prototypes, molds, and tooling. These machines excel at creating unique shapes, contours, and fine details that are difficult to achieve with other manufacturing methods.

8. Automation and Precision of CNC Mills

Both CNC machines and CNC mills offer automation and precision, but CNC mills excel in terms of precision due to their dedicated focus on milling operations. CNC mills utilize advanced software and tooling to achieve high levels of accuracy and repeatability. The ability to precisely control the cutting tools, workpiece positioning, and feed rates allows CNC mills to produce parts with exceptional precision, meeting the stringent requirements of industries where accuracy is paramount.

9. Cost Considerations of CNC Mills

The cost of CNC machines and CNC mills can vary based on various factors, including size, complexity, and specific capabilities. Generally, CNC mills tend to be more expensive compared to other types of CNC machines due to their specialized nature and the precise milling capabilities they offer. However, the investment in CNC mills is often justified by the increased productivity, efficiency, and quality they bring to the manufacturing process.

10. Choosing the Right Technology

When deciding between CNC machines and CNC mills, it is crucial to consider the specific requirements of your manufacturing needs. Consider factors such as the types of operations you need, the materials you will be working with, and the complexity of the parts you aim to produce. Consulting with experts in the field can help you make an informed decision, ensuring that you select the right technology to optimize your manufacturing process.