Introduction

Computer Numerical Control (CNC) laser cutting machines have come a long way in recent years. These machines are versatile and can be used to cut a variety of materials. In this article, we'll explore what CNC laser cutting machines are and how they work.

What is a CNC laser cutting machine??

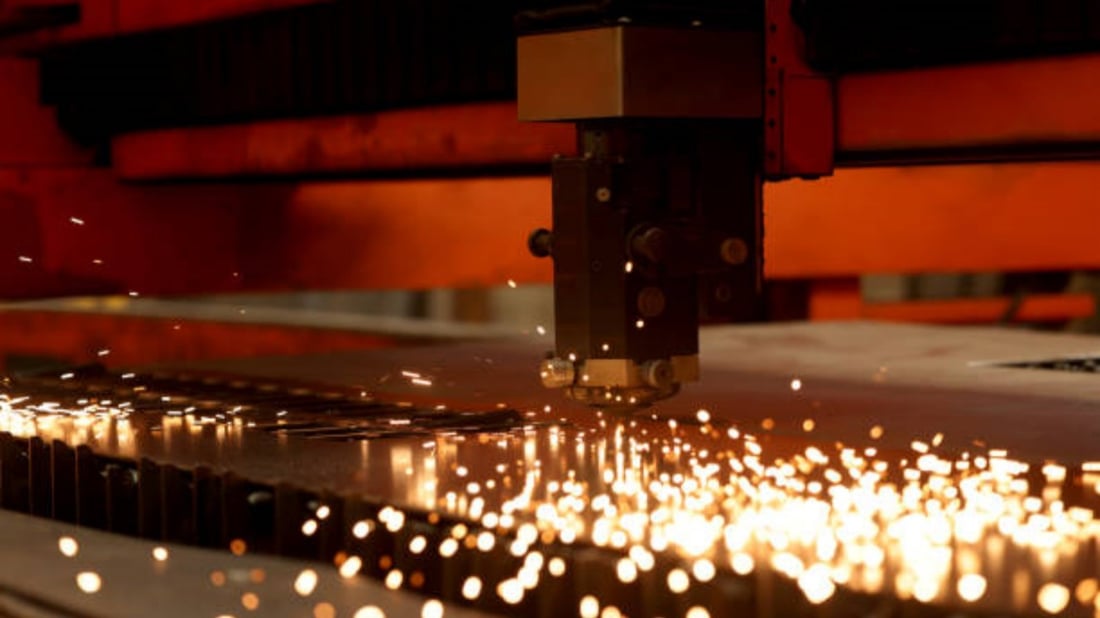

A CNC laser cutting machine is a device that uses laser technology to cut, engrave, or etch a wide range of materials such as metal, wood, acrylic, and plastic. The machine is operated using a computer program, which controls the laser beam's position and movement, allowing for precise cuts with a high degree of accuracy.

How Does a CNC Laser Cutting Machine Work?

A CNC laser cutting machine works by directing a laser beam onto the material being cut. The laser beam melts, vaporizes, or burns the material, creating a cut or an engraving. The machine is guided by computer software to ensure accuracy and precision.

Advantages of CNC Laser Cutting Machines

CNC laser cutting machines have several advantages over traditional cutting methods. They offer higher precision, versatility, and automation. CNC laser cutting machines can cut complex designs and shapes quickly and accurately. They also offer faster turnaround times and higher production rates.

Types of CNC Laser Cutting Machines

There are two main types of CNC laser cutting machines: CO2 lasers and fiber lasers. CO2 lasers are used for cutting non-metals such as paper, wood, and plastics. Fiber lasers are used for cutting metals such as steel and aluminum. Each type of laser has its advantages, and the choice depends on the material being cut.

Applications of CNC Laser Cutting Machines

CNC laser cutting machines are used in a variety of industries such as automotive, aerospace, electronics, and signage. They are used for cutting, engraving, and marking materials such as metal, plastic, rubber, and wood. CNC laser cutting machines are used to produce parts for machines, architectural models, and promotional material among other things.

Maintenance of CNC Laser Cutting Machines

Like any other machine, CNC laser cutting machines require maintenance. The machine should be inspected regularly for any wear and tear on its parts. The laser tube and optics should be checked and cleaned periodically to ensure proper functioning.

Choosing a CNC Laser Cutting Machine

When choosing a CNC laser cutting machine, the first consideration is the type of material to be cut. Then, take into account the size of the machine, precision, power, and speed of the laser. Also, consider the machine's maintenance costs and customer support services offered by the manufacturer.

Cost of CNC Laser Cutting Machines

The cost of a CNC laser cutting machine depends on its size, features, and capabilities. The price can range from a few thousand to hundreds of thousands of dollars. It is essential to determine the required functions and capacity of the machine before making a purchase decision.

Conclusion

CNC laser cutting machines are powerful and versatile tools utilized in a variety of industries. They offer great precision, automation, and versatility in cutting a variety of materials with speed and accuracy. Understanding the types, applications, and maintenance required is essential to make an informed decision when purchasing a CNC laser cutting machine.