The Importance of Milling Machines in the Manufacturing Industry

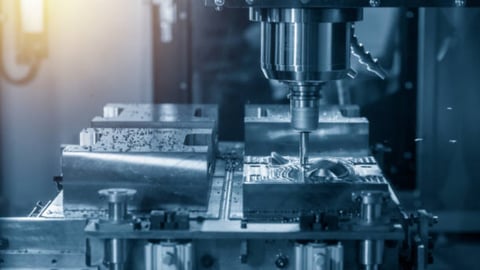

Milling machines are essential tools in the manufacturing industry, used for shaping and cutting various materials. They play a crucial role in precision machining, enabling the creation of intricate components and parts. There are different types of milling machines available, each with its own unique features and applications. In this article, we will explore the three basic types of milling machines and their uses.

1. Vertical Milling Machine: Versatile and Efficient

The vertical milling machine is one of the most common types of milling machines found in workshops and factories. As the name suggests, the spindle axis is vertically oriented. This machine is known for its versatility and efficiency in handling both simple and complex milling operations.

Vertical milling machines are equipped with a cutting tool that rotates about a vertical axis, allowing it to remove material from the workpiece. They are commonly used for tasks such as face milling, end milling, and drilling holes in various materials. These machines are especially useful for creating slots, grooves, and irregular surfaces.

2. Horizontal Milling Machine: Ideal for Heavy-Duty Cutting

Unlike vertical milling machines, horizontal milling machines have a horizontally oriented spindle axis. This type of machine is designed for heavy-duty cutting and is often used in industrial settings where high precision and productivity are required.

Horizontal milling machines are known for their stability and rigidity, making them suitable for machining large and heavy workpieces. They are commonly used in the automotive, aerospace, and shipbuilding industries. With their ability to perform various operations such as contour milling, gear cutting, and slotting, horizontal milling machines are essential for producing complex components.

3. Universal Milling Machine: The Swiss Army Knife of Milling

The universal milling machine is a versatile tool that combines the features of both vertical and horizontal milling machines. It allows for the flexibility to perform a wide range of milling operations, making it the Swiss army knife of milling machines.

With a swiveling table and a movable spindle, universal milling machines can be adjusted to different angles, enabling the creation of complex shapes and contours. These machines are widely used in industries such as tool and die making, prototype manufacturing, and general machining.

Conclusion

Millions of products we use daily rely on the precision and accuracy achieved through milling machines. Understanding the different types of milling machines - vertical, horizontal, and universal - is essential for selecting the right machine for specific applications. Whether you need to create simple parts or complex components, there is a milling machine designed to meet your needs.