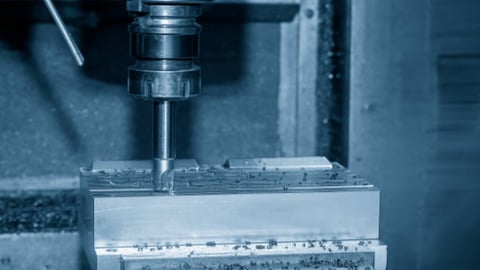

The Basics of CNC Milling

CNC milling is a widely used machining process that involves removing material from a workpiece using rotary cutters. It is a highly precise method that allows for the creation of complex shapes and designs. This article will provide an in-depth exploration of the various types of CNC milling, highlighting their features, applications, and advantages.

1. Vertical CNC Milling

Vertical CNC milling machines have a vertically oriented spindle, hence the name. This type of milling machine is commonly used for tasks that require cutting and drilling operations, such as creating slots and holes. Vertical mills are known for their versatility and ease of use, making them a popular choice for both beginners and professionals.

2. Horizontal CNC Milling

Horizontal CNC milling machines have a horizontally oriented spindle. They are primarily used for cutting large and heavy workpieces. Horizontal mills are capable of performing a variety of operations, including face milling, end milling, and plunge milling. They are often used in industries such as aerospace, automotive, and oil and gas.

3. 3-axis CNC Milling

3-axis CNC milling machines are the most common type of milling machines. They have three axes of motion: X, Y, and Z. These machines are capable of performing simple to complex milling operations on a workpiece. 3-axis milling is widely used in industries such as electronics, medical, and prototyping.

4. 4-axis CNC Milling

4-axis CNC milling machines have an additional rotary axis, usually referred to as the A-axis. This axis allows for the rotation of the workpiece, enabling the machine to create more intricate and complex shapes. 4-axis milling is commonly used in the production of molds, aerospace components, and jewelry.

5. 5-axis CNC Milling

5-axis CNC milling machines have two additional rotary axes, known as the A-axis and the B-axis. This type of milling machine offers the highest level of precision and flexibility. It allows for the simultaneous machining of multiple sides of a workpiece, reducing setup time and increasing productivity. 5-axis milling is extensively used in industries such as aerospace, automotive, and medical.

6. CNC Milling with Live Tooling

CNC milling machines with live tooling capabilities have additional tool stations that can hold rotating cutting tools. This enables the machine to perform milling, drilling, and tapping operations in a single setup. Live tooling is commonly used in industries that require complex and precise machining, such as the production of medical implants and aerospace components.

7. CNC Milling with High-Speed Spindles

CNC milling machines with high-speed spindles are designed to operate at significantly faster speeds than conventional milling machines. These machines are capable of achieving high material removal rates, resulting in shorter machining times. High-speed milling is often used in industries that require the production of small and intricate parts, such as electronics and micro-machining.

8. CNC Milling with Gantry Mills

Gantry mills, also known as bridge mills, are large CNC milling machines with a bridge-like structure. They are primarily used for machining large and heavy workpieces that require high precision. Gantry mills are commonly used in industries such as aerospace, automotive, and marine.

9. CNC Milling with Multitasking Machines

Multitasking machines combine the capabilities of CNC milling and turning in a single machine. These machines can perform both milling and turning operations, eliminating the need for multiple setups and reducing production time. Multitasking machines are commonly used in industries that require the production of complex and high-precision parts, such as the aerospace and automotive industries.

10. CNC Milling with Swiss-Type Machines

Swiss-type machines, also known as Swiss lathes, are specialized CNC machines that are primarily used for small and precise parts. These machines use a sliding headstock and guide bushing to support and guide the workpiece, resulting in excellent precision. Swiss-type machines are commonly used in industries such as medical, watchmaking, and electronics.