5-axis CNC machining offers unmatched precision and versatility compared to traditional 3-axis machining. With the ability to move in five different directions simultaneously, this technology can produce complex, intricate parts with ease.

Increased Efficiency with 5-Axis CNC Machining

One of the main benefits of 5-axis CNC machining is the ability to complete a part in a single setup, reducing lead times and increasing productivity. This technology eliminates the need for multiple setups and reduces the risk of errors.

Enhanced Surface Finish and Quality

5-axis CNC machining allows for better access to different angles and surfaces of a part, resulting in a superior surface finish. This technology is ideal for producing high-quality, precision components with tight tolerances.

Cost-Effectiveness of 5-Axis CNC Machining

While 5-axis CNC machining may initially seem more expensive than traditional machining methods, it can actually be more cost-effective in the long run. The increased efficiency and reduced setup times result in lower production costs and higher quality parts.

Complex Geometries Made Easy

With 5-axis CNC machining, complex geometries that would be difficult or impossible to achieve with traditional machining methods can be easily accomplished. This technology is ideal for industries that require intricate and precise parts.

Applications of 5-Axis CNC Machining

5-axis CNC machining is used in a wide range of industries, including aerospace, automotive, medical, and defense. This technology is ideal for producing prototypes, custom components, and low-volume production runs with high precision and accuracy.

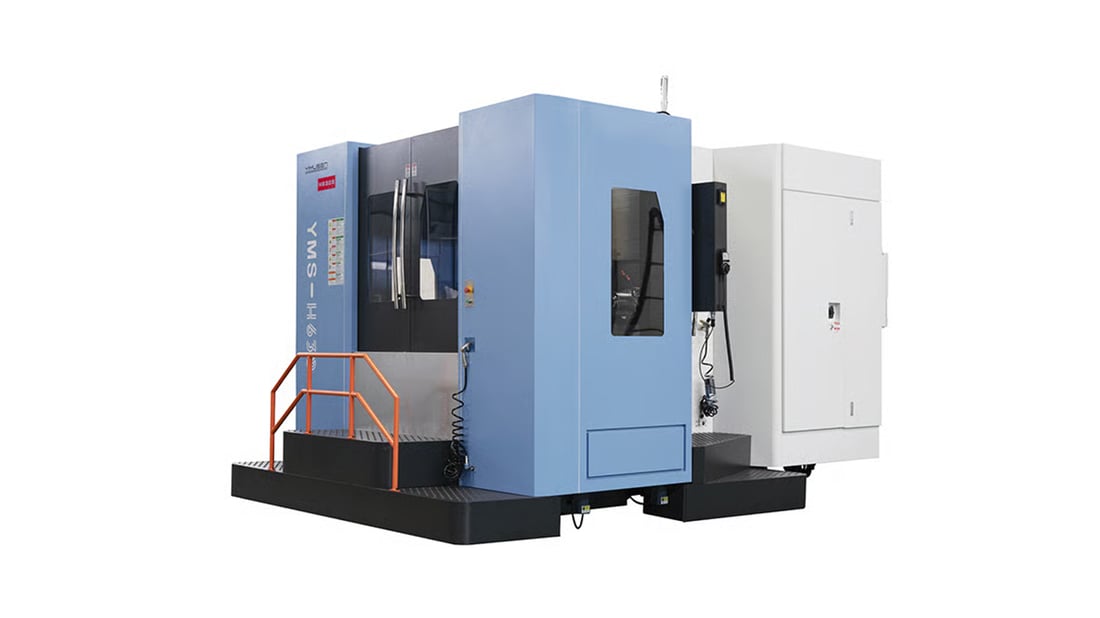

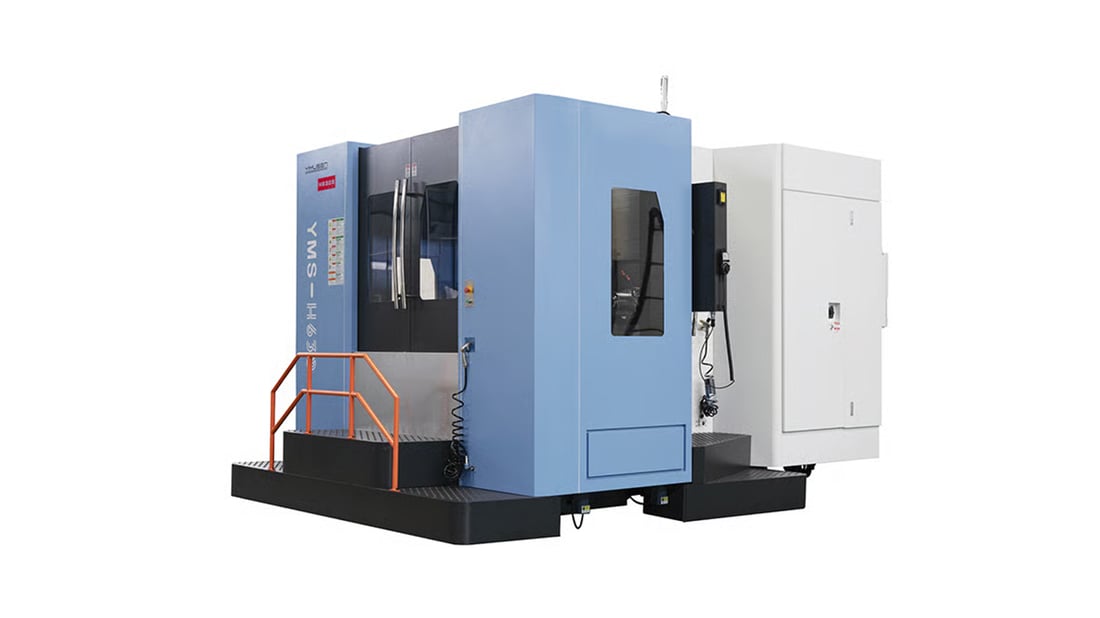

Choosing the Right 5-Axis CNC Machine

When selecting a 5-axis CNC machine, it's important to consider factors such as the size of the parts you will be machining, the materials you will be working with, and your production requirements. It's also essential to choose a machine that offers reliability, accuracy, and efficiency.

Training and Skill Required for 5-Axis CNC Machining

Operating a 5-axis CNC machine requires specialized training and expertise. Machinists must be skilled in programming, tooling, and understanding the complexities of multi-axis machining. Proper training is essential to ensure efficient and accurate production.

Future Trends in 5-Axis CNC Machining

As technology continues to advance, we can expect to see further improvements in 5-axis CNC machining. This includes faster machining speeds, enhanced software capabilities, and the integration of automation and robotics for increased efficiency and productivity.

Conclusion

In conclusion, 5-axis CNC machining is a game-changer for industries that require high precision, complex components. With its numerous advantages, including increased efficiency, superior quality, and cost-effectiveness, this technology is revolutionizing the manufacturing process.

Quote Inquiry

contact us