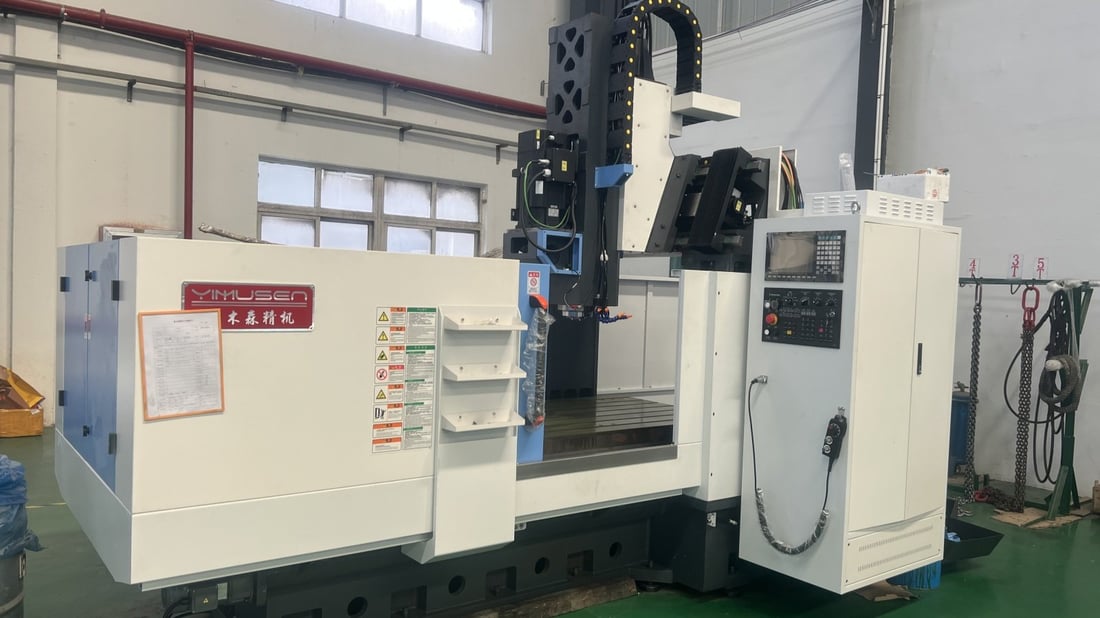

Introduction: Exploring the L1013 horizontal spindle machining centre

The L1013 Horizontal Spindle Machining Centre is a cutting-edge tool revolutionizing the manufacturing industry. Combining precision, efficiency, and versatility, this machine has become a game-changer for many businesses. In this article, we will delve into the various aspects of the L1013 Horizontal Spindle Machining Centre, exploring its features, benefits, and applications. Whether you are a seasoned professional or a curious beginner, join us on this informative journey to uncover the potential of this remarkable machining centre.

Enhancing Precision: Understanding the L1013's Spindle Capability

The L1013 Horizontal Spindle Machining Centre boasts an exceptional spindle capability, making it a top choice for precision-focused industries. With its horizontal setup, this machine ensures optimal stability during high-speed operations. The rigid structure minimizes vibrations, resulting in precise and accurate cuts. The L1013's spindle also offers a wide range of rotational speeds, allowing operators to tailor their machining process according to specific requirements. This capability, combined with advanced control systems, guarantees consistently high-quality output, meeting the most demanding industry standards.

Boosting Efficiency: Exploring the L1013's Rapid Tool Changer

Efficiency is a crucial factor in any manufacturing environment, and the L1013 Horizontal Spindle Machining Centre delivers on this front. Equipped with a rapid tool changer, this machine enables seamless transitions between different tools during the machining process. The automated tool change significantly reduces downtime, maximizing productivity and minimizing human errors. This feature is particularly valuable for complex projects that involve multiple tooling operations, as the L1013 streamlines the workflow, saving time and resources.

Enhanced Flexibility: Unleashing the L1013's Multi-Axis Capability

The L1013 Horizontal Spindle Machining Centre offers exceptional flexibility through its multi-axis capability. With its advanced design, this machine allows for simultaneous machining on multiple sides of a workpiece, eliminating the need for additional setups. This versatility is invaluable for intricate and complex components, as it reduces production time and enhances overall efficiency. The L1013's multi-axis capability empowers manufacturers to tackle a broader range of projects, opening doors to new opportunities and expanding their capabilities.

Unmatched Versatility: Utilizing the L1013 for Various Industries

The L1013 Horizontal Spindle Machining Centre finds its place in numerous industries, thanks to its unmatched versatility. In the automotive sector, it excels in producing engine components with tight tolerances. For aerospace manufacturers, the L1013 enables the machining of complex airframe parts with precision. Additionally, the machine's flexibility makes it a preferred choice for the medical industry, where it can create intricate surgical instruments. From electronics to mold-making, the L1013 proves its adaptability across multiple sectors, making it a valuable asset for any manufacturing facility.

Optimizing Workflow: Harnessing the L1013's Advanced Control Systems

To ensure optimal performance and productivity, the L1013 Horizontal Spindle Machining Centre incorporates advanced control systems. These systems provide operators with intuitive interfaces and real-time monitoring, allowing for efficient workflow management. With features like tool life management and predictive maintenance, the L1013 minimizes unexpected downtime and reduces maintenance costs. The integration of smart technologies optimizes the machining process, empowering manufacturers to achieve higher output and meet strict deadlines consistently.

Streamlining Production: Implementing Automation with the L1013

Automation has become a key driver in modern manufacturing, and the L1013 Horizontal Spindle Machining Centre embraces this trend. The machine seamlessly integrates with robotics and automation systems, enabling unmanned operations. By eliminating the need for manual intervention, the L1013 enhances safety, reduces labor costs, and increases overall productivity. With its user-friendly interface and compatibility with various automation solutions, this machining centre offers a seamless transition towards a more efficient and competitive manufacturing environment.

Unveiling Precision: Showcasing L1013's Quality Assurance Features

Quality assurance is paramount in any manufacturing process, and the L1013 Horizontal Spindle Machining Centre ensures exceptional results through its innovative features. The machine incorporates cutting-edge measurement systems, enabling real-time monitoring and feedback. This capability allows operators to identify deviations and make necessary adjustments promptly. Additionally, the L1013's automatic tool and workpiece measurement systems ensure consistent quality throughout the production cycle. With its focus on precision and quality assurance, the L1013 safeguards the reputation and trust of manufacturers in various industries.

Investment Worth Making: Analyzing the Cost-Benefit of the L1013

The L1013 Horizontal Spindle Machining Centre represents a significant investment for any manufacturing facility. However, when evaluating the cost-benefit ratio, its advantages become apparent. The machine's precision, efficiency, and versatility contribute to increased productivity, reduced downtime, and improved product quality. These factors, coupled with its compatibility with automation systems, translate into long-term cost savings. By streamlining production, expanding capabilities, and ensuring reliable performance, the L1013 proves to be a worthy investment for manufacturers striving for excellence and competitiveness.

Conclusion: The L1013 Horizontal Spindle Machining Centre Unleashes Potential

The L1013 Horizontal Spindle Machining Centre has revolutionized the manufacturing industry with its precision, efficiency, and versatility. From enhancing precision through its spindle capability to streamlining production via automation, this machine unlocks new possibilities for manufacturers across various sectors. With its advanced control systems, multi-axis capability, and focus on quality assurance, the L1013 empowers businesses to navigate the ever-evolving market demands. Investing in the L1013 Horizontal Spindle Machining Centre is a strategic move towards staying competitive, delivering high-quality products, and achieving operational excellence.