The Significance of Thermal Stability

Precision engineering refers to the process of designing and producing high-precision components with tight tolerances. One crucial factor that must be considered in precision engineering is thermal stability. Thermal stability relates to the ability of a material or component to withstand changes in temperature without deforming or losing its dimensional accuracy.

Effects of Temperature on Precision Components

Temperature fluctuations can have a significant impact on the performance of precision components. Changes in temperature can cause materials to expand or contract, leading to dimensional changes that may affect the functionality of the component. It is essential to ensure that precision components maintain their structural integrity and dimensional stability under varying thermal conditions.

Material Selection for Thermal Stability

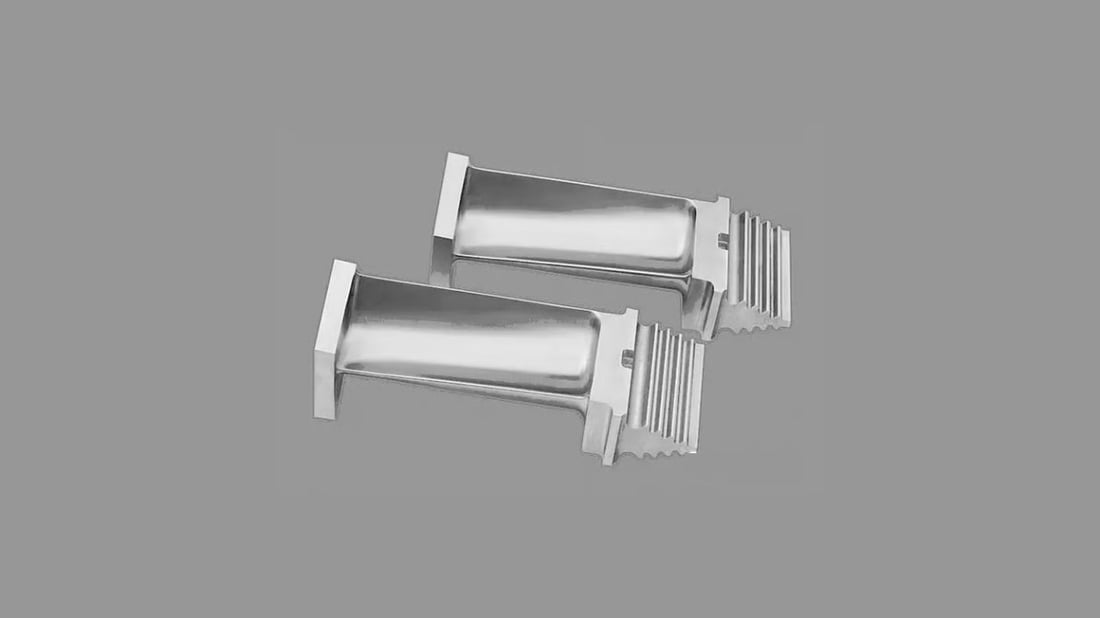

When designing precision components, the choice of materials plays a critical role in determining thermal stability. Certain materials have better thermal conductivity and coefficient of expansion, making them more suitable for applications where thermal stability is crucial. Materials like stainless steel, titanium, and ceramics are commonly used in precision engineering due to their excellent thermal stability characteristics.

Design Considerations for Thermal Stability

In addition to material selection, the design of precision components also influences thermal stability. Factors such as geometry, surface finish, and heat dissipation capabilities must be taken into account during the design process to ensure optimal thermal stability. Designing components with proper thermal management features can help minimize the effects of temperature fluctuations.

Testing and Validation of Thermal Stability

To ensure that precision components meet thermal stability requirements, thorough testing and validation protocols must be implemented. Thermal cycling tests, thermal shock tests, and finite element analysis (FEA) simulations are some of the techniques used to evaluate the thermal stability of precision components. These tests help identify any potential weaknesses in the design and manufacturing process.

Benefits of Maintaining Thermal Stability

Maintaining

Thermal Stability in Precision Engineering offers several benefits, including enhanced performance, extended operational lifespan, and improved reliability. Components that exhibit good thermal stability are better equipped to withstand harsh operating conditions and temperature variations, resulting in more robust and durable products.

Challenges in Achieving Thermal Stability

Despite the importance of thermal stability in precision engineering, there are several challenges associated with achieving and maintaining it. Factors such as material selection, design complexity, manufacturing processes, and environmental conditions can all impact the thermal stability of precision components. Overcoming these challenges requires a comprehensive understanding of the underlying principles and careful attention to detail.

Applications of Thermal Stability in Precision Engineering

Thermal stability is a critical consideration in various industries that rely on precision engineering, including aerospace, automotive, medical, and electronics. In aerospace applications, for example, components must maintain their dimensional accuracy and structural integrity under extreme temperature fluctuations experienced during flight. Similarly, in medical devices, thermal stability is essential for ensuring consistent and reliable performance.

Future Trends in Thermal Stability Technology

As technology advances and the demand for high-precision components continues to grow, the focus on thermal stability in precision engineering is expected to increase. Innovative materials, advanced manufacturing techniques, and sophisticated thermal management solutions are likely to emerge to address the evolving requirements of thermal stability. The integration of smart sensors and predictive maintenance strategies could also play a significant role in optimizing thermal stability in precision engineering.

Conclusion

In conclusion, thermal stability is a fundamental aspect of precision engineering that influences the quality, reliability, and performance of precision components. By carefully considering material selection, design factors, testing protocols, and application-specific requirements, engineers can ensure that precision components exhibit optimal thermal stability. As technology evolves and industries demand higher levels of precision, the importance of thermal stability in precision engineering will only continue to grow.

Quote Inquiry

contact us