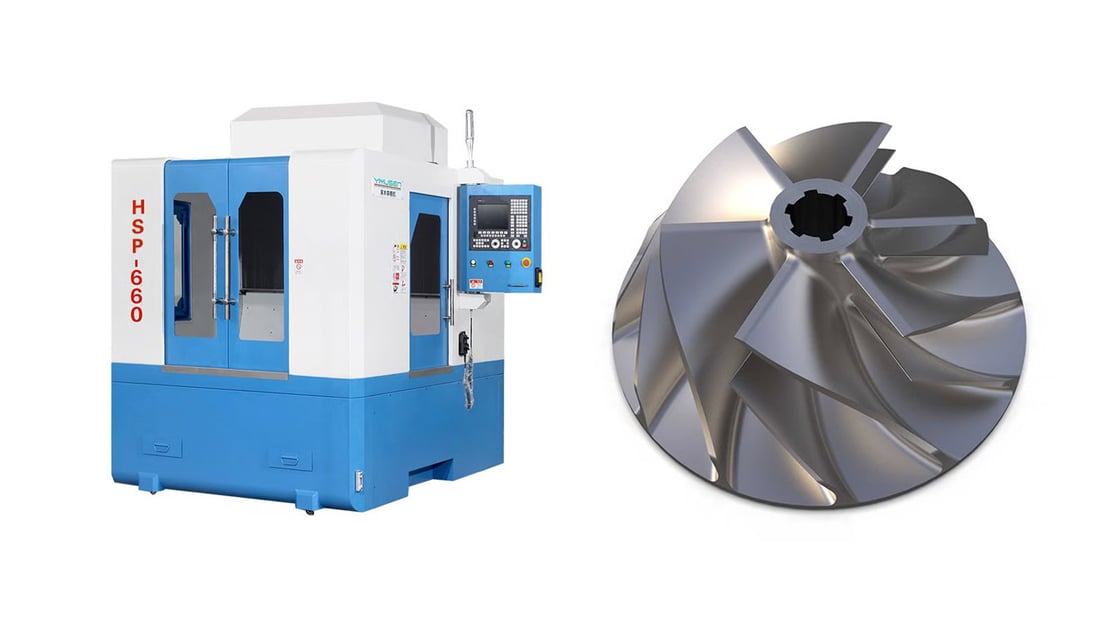

A Horizontal Machining Center (HMC) is a machine tool used for machining various materials. It has a horizontal spindle orientation, which allows for smoother and more efficient machining compared to vertical machining centers.

Advantages of Using a Horizontal Machining Center

One of the key advantages of using a Horizontal Machining Center is its ability to handle heavy workpieces with ease. The horizontal spindle orientation also allows for better chip evacuation, improved tool life, and higher accuracy in machining operations.

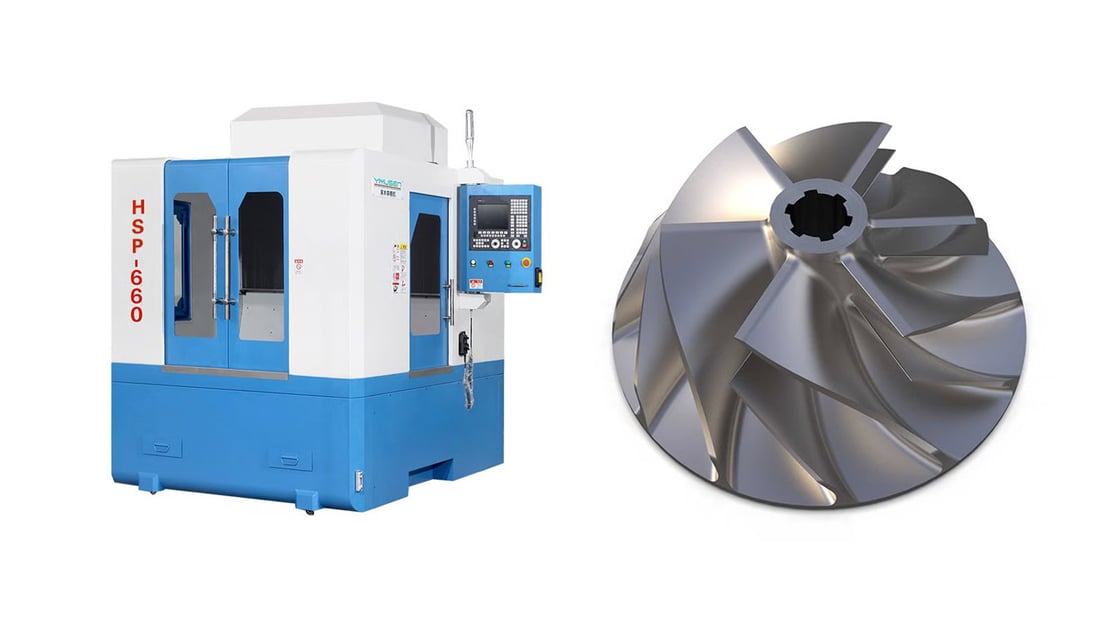

Applications of Horizontal Machining Centers

Horizontal Machining Centers are widely used in industries such as automotive, aerospace, and defense for machining complex components. They are ideal for milling, drilling, tapping, and boring operations on large workpieces.

Features of a Horizontal Machining Center

A typical Horizontal Machining Center is equipped with a pallet changer, tool magazine, coolant system, and a control panel for programming machining operations. Some HMCs also come with advanced features such as high-speed spindles and automatic tool changers.

Types of Horizontal Machining Centers

There are different types of Horizontal Machining Centers available, such as 4-axis HMCs, 5-axis HMCs, and palletized HMCs. Each type is designed for specific machining tasks and offers unique capabilities for increased productivity.

Factors to Consider When Choosing a Horizontal Machining Center

When selecting a Horizontal Machining Center for your machining needs, consider factors such as spindle speed, tool capacity, workpiece size, automation options, and control system. It is important to choose an HMC that can meet the demands of your production requirements.

Advancements in Horizontal Machining Center Technology

With advancements in technology, modern Horizontal Machining Centers are equipped with features such as CNC control, adaptive machining, real-time monitoring, and predictive maintenance. These features enhance precision, speed, and overall efficiency in machining operations.

Comparing Horizontal Machining Centers with Vertical Machining Centers

While Vertical Machining Centers are suitable for certain applications, Horizontal Machining Centers offer distinct advantages in terms of chip evacuation, tool life, and spindle rigidity. HMCs are preferred for heavy-duty machining tasks and large workpieces.

Training and Skills Required for Operating a Horizontal Machining Center

Operating a Horizontal Machining Center requires proper training and skills in programming, tooling, setup, and maintenance. Operators must understand the machine's capabilities and safety protocols to ensure smooth and efficient machining operations.

Future Trends in Horizontal Machining Centers

As technology continues to evolve, the future of Horizontal Machining Centers is moving towards increased automation, integration with smart manufacturing systems, and enhanced connectivity. These developments aim to improve productivity, reduce downtime, and optimize machining processes.

Quote Inquiry

contact us