Introduction

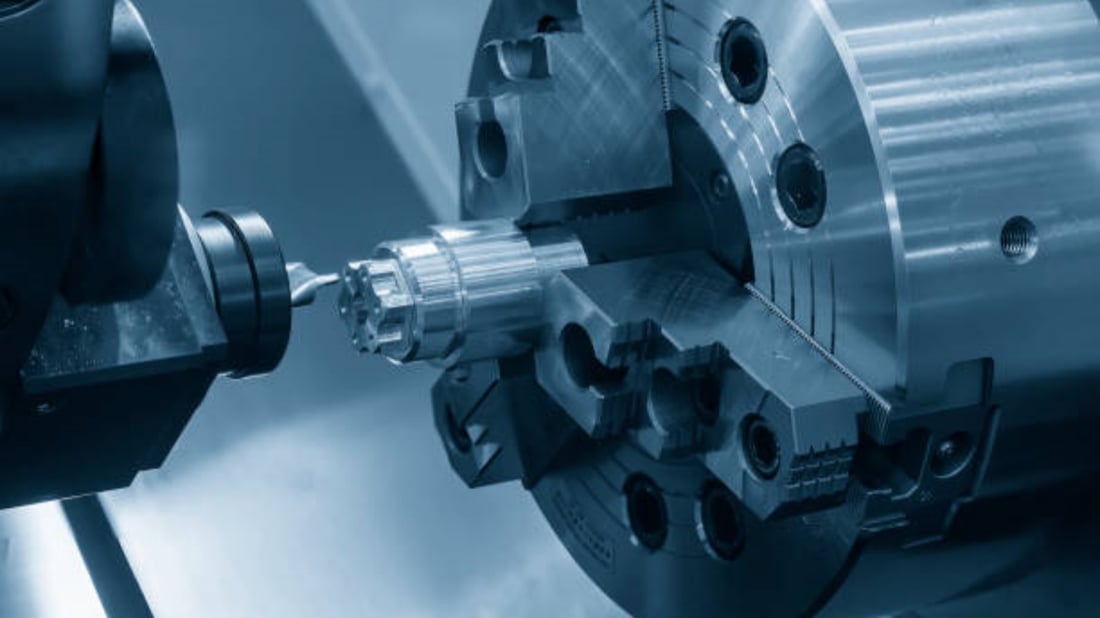

A large CNC milling machine is a powerful tool that can streamline and enhance production in a variety of industries. With its ability to handle large-scale projects, this machine offers numerous benefits that can improve efficiency and precision. In this article, we will explore the advantages of using a large CNC milling machine and how it can contribute to the success of your business.

Increased Capacity and Versatility of Using a Large CNC Milling Machine

One of the primary advantages of a large CNC milling machine is its increased capacity. With a larger working area, this machine can accommodate larger workpieces, allowing for the production of larger and more complex parts. Additionally, its versatility enables the milling of various materials, such as metals, plastics, and composites. This flexibility opens up a wide range of possibilities for manufacturers in different industries.

Improved Precision and Accuracy of Using a Large CNC Milling Machine

Large CNC milling machines are renowned for their exceptional precision and accuracy. Equipped with advanced computer-controlled systems, these machines can execute complex milling operations with high levels of accuracy, ensuring consistent and precise results. This level of precision is particularly beneficial for industries that require tight tolerances and intricate designs.

Enhanced Productivity and Efficiency

By automating the milling process, large CNC milling machines greatly enhance productivity and efficiency. These machines can operate continuously for extended periods, requiring minimal human intervention. This automation reduces the risk of errors and allows operators to focus on other tasks, leading to increased productivity and faster turnaround times.

Cost Savings of Using a Large CNC Milling Machine

Although large CNC milling machines may require a significant investment upfront, they can ultimately result in long-term cost savings. With their high level of precision, these machines minimize material waste and reduce the need for manual rework. Additionally, their automation capabilities reduce labor costs and minimize the risk of human error, further contributing to cost savings over time.

Improved Safety of Using a Large CNC Milling Machine

Large CNC milling machines are designed with safety in mind. They are equipped with various safety features, such as emergency stops, protective enclosures, and automatic tool changers, to ensure the well-being of operators. By minimizing the risk of accidents and injuries, these machines create a safer working environment for employees.

Shortened Lead Times of Using a Large CNC Milling Machine

With their ability to handle large-scale projects and automate the milling process, large CNC milling machines can significantly shorten lead times. Manufacturers can efficiently produce a higher volume of parts within a shorter timeframe, allowing them to meet tight deadlines and satisfy customer demands promptly. This increased efficiency can give businesses a competitive edge in their respective industries.

Consistent Quality of Using a Large CNC Milling Machine

Large CNC milling machines offer consistent quality in every part they produce. With their precise and repeatable movements, these machines ensure that each workpiece meets the required specifications. By eliminating variations and inconsistencies, businesses can deliver high-quality products consistently, enhancing customer satisfaction and loyalty.

Flexibility in Design Iterations of Using a Large CNC Milling Machine

Large CNC milling machines enable businesses to iterate designs more easily. With their ability to handle complex and intricate designs, these machines allow manufacturers to experiment and make design modifications without significant time and cost implications. This flexibility facilitates innovation and encourages continuous improvement in product development.

Conclusion

A large CNC milling machine offers numerous benefits for businesses in various industries. From increased capacity and versatility to improved precision and efficiency, these machines have the potential to revolutionize production processes. By investing in a large CNC milling machine, businesses can enhance their capabilities, reduce costs, and stay ahead of the competition.