Introduction

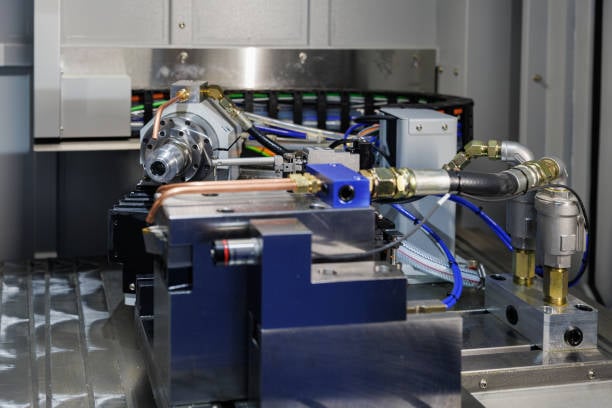

A small cnc tube bender is a machine used in manufacturing processes that requires precision bending of metal tubes. With the help of a computer numerical control (CNC) system, it can bend tubes to exact specifications with minimal human intervention.

Benefits of Using a Small CNC Tube Bender

When it comes to tube bending, using a small CNC tube bender provides numerous advantages. Here are some of them:

1. Precise Bending

Small CNC tube benders have a higher accuracy rate than manual benders. This is because a CNC system controls the bending process, ensuring that each bend is precise and consistent.

2. Increased Productivity

Small CNC tube benders are automated, which means that they can work on multiple tubes at the same time. This results in faster production times and a significant increase in productivity.

3. Cost-effective

Small CNC tube benders offer higher productivity rates while also reducing costs associated with manual benders, such as labor costs and scrap material costs. This results in cost savings for the manufacturer in the long run.

4. Versatility

A small CNC tube bender can work with a wide variety of metal tubes of different thicknesses, shapes, and materials. This versatility ensures that it can be used for different applications, from automotive to aerospace industries.

5. Consistency

Using a small CNC tube bender ensures that each bend is consistent, regardless of the operator. This is because the machine follows exact specifications provided by the CNC system, leading to higher-quality products and satisfied customers.

6. Reduced Waste

Since small CNC tube benders offer precision bending, there is less waste material. Precision cuts mean that less material is used, which can reduce the cost of the raw material, and there is less scrap material to dispose of.

7. Better Safety Measures

Small CNC tube benders are safer to operate since they do not require manual intervention. The CNC system controls the bending process, reducing the risk of operator error and accidents in the workplace.

8. Greater Flexibility

A small CNC tube bender can be programmed to bend tubes into complex shapes and angles, allowing for greater flexibility in design and production. This makes the machine ideal for custom orders and one-off productions.

9. Reduced Set-up Time

Small CNC tube benders require minimal set-up time since they are automated and do not require manual adjustments. This reduces downtime and increases productivity rates.

10. Easy Maintenance

Small CNC tube benders are low-maintenance machines that require minimal upkeep. Regular maintenance checks and cleaning will help ensure that the machine functions at an optimal level and has a long lifespan.

Conclusion

A small CNC tube bender is a valuable investment for manufacturers who require precision tube bending. The machine offers numerous advantages, including higher productivity, precision bending, cost savings, and greater flexibility. By using a small CNC tube bender, manufacturers can ensure consistent, high-quality products while reducing costs and waste material.