Introduction

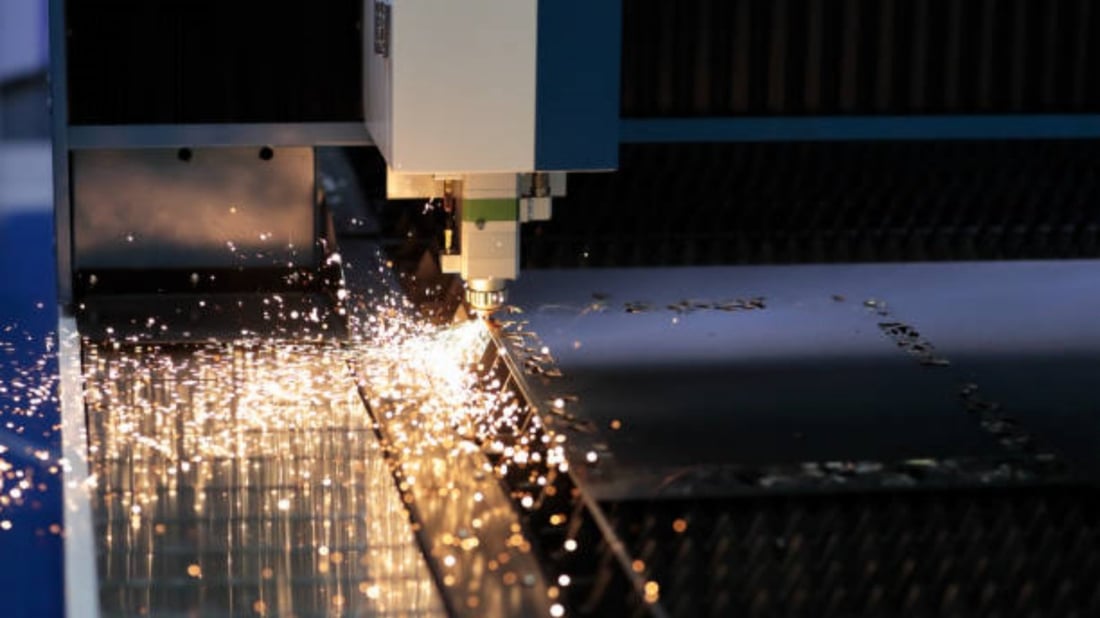

When it comes to cutting fabrics, precision and efficiency are of utmost importance. Traditional methods may not always provide the desired results, which is why many industries are turning to cnc fabric laser cutting machines. These advanced machines utilize laser technology to cut fabrics with remarkable accuracy and speed. In this article, we will explore the various advantages of using a CNC fabric laser cutting machine.

1. Enhanced Precision

One of the primary reasons why industries opt for CNC fabric laser cutting machines is their ability to deliver unparalleled precision. These machines utilize a high-powered laser beam that can cut through fabrics with incredible accuracy. Unlike other cutting methods, a CNC fabric laser cutting machine ensures clean and precise cuts, ensuring minimal waste and superior finished products.

2. Increased Efficiency of Using a CNC Fabric Laser Cutting Machine

Efficiency is a crucial factor in any manufacturing process, and CNC fabric laser cutting machines excel in this aspect. These machines work at high speeds, allowing for rapid cutting and increased productivity. With the ability to cut through multiple layers of fabric at once, a CNC fabric laser cutting machine can significantly reduce production time, helping businesses meet their deadlines more efficiently.

3. Versatility

A CNC fabric laser cutting machine is a versatile tool that can handle a wide range of fabrics. Whether you're working with delicate materials like silk and chiffon or denser fabrics like denim and leather, these machines can adapt to the specific requirements of each material. This versatility makes CNC fabric laser cutting machines suitable for various industries, including fashion, automotive, and upholstery.

4. Minimized Material Waste

Traditional cutting methods often result in significant material waste due to imprecise cuts and inefficiency. However, CNC fabric laser cutting machines can minimize material waste by accurately cutting along predetermined patterns. By optimizing the layout and reducing the gaps between pattern pieces, these machines ensure maximum utilization of the fabric, reducing overall production costs.

5. Complex Design Capabilities

With a CNC fabric laser cutting machine, complex and intricate designs can be easily achieved. The machine's computer numerical control (CNC) system allows for precise control over the cutting process, enabling the creation of intricate patterns and shapes. This feature is especially beneficial for industries that require detailed designs, such as apparel manufacturing and textile art.

6. Reduced Labor Costs of Using a CNC Fabric Laser Cutting Machine

By automating the cutting process, CNC fabric laser cutting machines can significantly reduce labor costs. These machines require minimal human intervention, as the cutting process is controlled by a computer program. This automation not only saves time but also eliminates the need for manual cutting, resulting in cost savings for businesses in the long run.

7. Improved Safety

Traditional fabric cutting methods often involve the use of sharp blades and manual handling, posing a risk of injuries. In contrast, CNC fabric laser cutting machines offer a safer alternative. These machines are equipped with safety features such as enclosed cutting areas and automatic shut-off mechanisms, minimizing the risk of accidents and ensuring a safer working environment.

8. Easy Replication

Reproducing designs accurately can be a challenging task when using traditional cutting methods. However, CNC fabric laser cutting machines simplify the replication process. Once a design is programmed into the machine, it can be easily replicated multiple times with consistent precision. This feature is particularly beneficial for industries that require mass production of identical fabric pieces.

9. Minimal Maintenance

CNC fabric laser cutting machines are designed to be low-maintenance, reducing downtime and increasing operational efficiency. Regular cleaning and periodic servicing are typically the only maintenance requirements for these machines. This allows businesses to focus on their production processes without worrying about frequent breakdowns or costly repairs.

10. Cost-Effective in the Long Run

Though CNC fabric laser cutting machines may require a significant upfront investment, they prove to be cost-effective in the long run. By improving efficiency, minimizing material waste, and reducing labor costs, these machines offer a high return on investment. The long-term benefits, including increased productivity and superior product quality, make CNC fabric laser cutting machines a worthwhile investment for businesses in the textile industry.