Introduction

When it comes to precision and efficiency in metalworking, the CNC aluminium milling machine stands out as a vital tool in various industries. This advanced piece of equipment utilizes computer numerical control (CNC) technology to automate the milling process, resulting in faster production and higher accuracy. In this article, we will explore the numerous benefits of using a CNC aluminium milling machine, from its ability to handle complex designs to its cost-effectiveness and versatility.

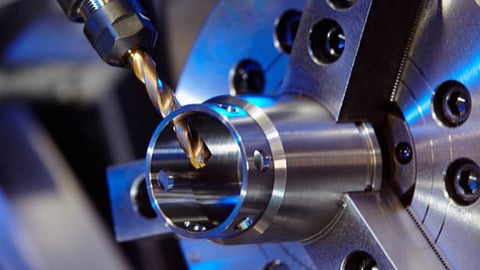

1. Enhanced Precision and Accuracy of Using a CNC Aluminium Milling Machine

One of the primary advantages of using a CNC aluminium milling machine is its ability to produce highly precise and accurate results. By utilizing computer programming and automation, these machines can consistently achieve tight tolerances and intricate designs that may be challenging to replicate manually. With the ability to make precise cuts, holes, and shapes, CNC aluminium milling machines ensure that every workpiece meets the required specifications with minimal errors.

2. Increased Efficiency and Productivity of Using a CNC Aluminium Milling Machine

The automation provided by CNC aluminium milling machines significantly enhances efficiency and productivity. Traditional milling methods often require manual adjustments and frequent operator intervention, leading to longer processing times. However, with a CNC machine, once the program is set and the workpiece is secured, the machine can operate continuously without constant supervision. This frees up operators to focus on other tasks, leading to increased productivity and reduced downtime.

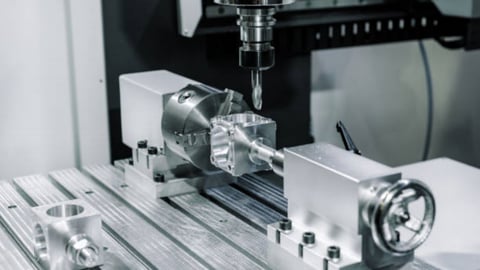

3. Handling Complex Designs with Ease

CNC aluminium milling machines excel at handling complex designs that may be challenging to achieve using traditional methods. The ability to program intricate tool paths and execute them accurately allows for the creation of highly detailed components and parts. With the right software and skilled operators, these machines can produce intricate shapes, contours, and patterns that meet even the most demanding design requirements.

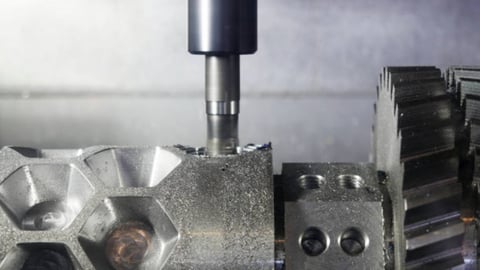

4. Versatility in Material Compatibility of Using a CNC Aluminium Milling Machine

Another significant advantage of CNC aluminium milling machines is their versatility in working with various materials. While specifically designed for aluminium milling, these machines can also work with other metals, such as steel, brass, and copper. This flexibility allows manufacturers to use the same machine for different projects and materials, eliminating the need for multiple specialized machines and reducing costs.

5. Cost-Effectiveness of Using a CNC Aluminium Milling Machine

Although the initial investment in a CNC aluminium milling machine may be higher than traditional milling equipment, the long-term cost-effectiveness is undeniable. These machines offer higher production rates, reduced labor costs, and decreased material waste. Additionally, the precision and accuracy provided by CNC machines minimize the likelihood of errors that could result in expensive rework or scrapped parts. Overall, the cost savings realized through increased efficiency and reduced waste make CNC aluminium milling machines a wise investment.

6. Improved Safety of Using a CNC Aluminium Milling Machine

CNC aluminium milling machines prioritize the safety of operators and workers. The automation provided by these machines significantly reduces the risk of accidents and injuries associated with manual milling. Operators are not required to be in close proximity to the cutting tool, minimizing the potential for accidents caused by human error. Additionally, modern CNC machines are equipped with safety features, such as emergency stop buttons and protective enclosures, ensuring a safe working environment.

7. Greater Consistency and Reproducibility of Using a CNC Aluminium Milling Machine

Consistency and reproducibility are critical factors in manufacturing. CNC aluminium milling machines offer exceptional consistency, ensuring that each workpiece produced is identical in quality and specifications. Whether producing a single prototype or a large batch of components, CNC machines can replicate the programmed design precisely, eliminating variations caused by human factors. This level of consistency is essential for industries that require uniformity and reliability in their products.

8. Faster Prototyping and Time-to-Market of Using a CNC Aluminium Milling Machine

In today's fast-paced market, reducing the time it takes to bring a product to market is crucial. CNC aluminium milling machines expedite the prototyping process by quickly transforming digital designs into physical prototypes. This rapid prototyping capability allows manufacturers to iterate and improve their designs more efficiently, reducing development cycles and accelerating time-to-market. By streamlining the design and production process, CNC machines contribute to increased competitiveness and agility in the industry.

9. Improved Surface Finish and Aesthetics

CNC aluminium milling machines can achieve superior surface finishes compared to traditional milling methods. The precision cutting and smooth tool movements result in workpieces with excellent surface quality, reducing the need for additional finishing processes. This not only saves time but also enhances the aesthetics of the final product. The ability to achieve high-quality surface finishes is particularly advantageous for industries that require visually appealing components, such as automotive, aerospace, and consumer electronics.

10. Environmental Friendliness of Using a CNC Aluminium Milling Machine

CNC aluminium milling machines contribute to a greener and more sustainable manufacturing environment. These machines operate with high efficiency, minimizing energy consumption and reducing the carbon footprint of the production process. Additionally, the accuracy and precision of CNC machines lead to decreased material waste, optimizing material usage and reducing the overall environmental impact. By adopting CNC aluminium milling machines, manufacturers can align their operations with eco-friendly practices while maintaining high-quality production standards.