Introduction

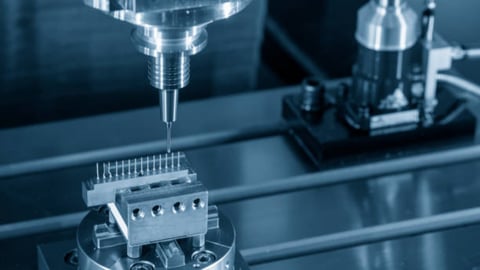

When it comes to precision machining, CNC milling machines are a crucial tool in various industries. In particular, the use of CNC milling machines for aluminum has become increasingly popular due to the many advantages they offer. This article explores the benefits of utilizing CNC milling machines for aluminum, highlighting how they improve efficiency, accuracy, and overall productivity.

1. Enhanced Precision of CNC Milling Machines for Aluminum

One of the main advantages of using CNC milling machines for aluminum is the enhanced precision they provide. These machines are equipped with advanced computer numerical control systems that allow for precise and accurate movements. This level of precision ensures that every cut, hole, and surface finish is produced with consistent accuracy, meeting the highest quality standards.

2. Increased Efficiency of CNC Milling Machines for Aluminum

CNC milling machines for aluminum offer increased efficiency compared to traditional manual milling methods. With the ability to program and automate the machining process, these machines can work continuously, reducing downtime and increasing productivity. This automation also eliminates the need for manual intervention, allowing operators to focus on other critical tasks, further improving overall efficiency.

3. Versatility in Design

Aluminum is a popular choice in many industries due to its lightweight and corrosion-resistant properties. CNC milling machines offer versatility in designing aluminum parts, allowing for complex shapes and intricate details. With the ability to create 3D models and simulate machining processes, these machines enable engineers to optimize designs and achieve the desired outcome with precision.

4. Faster Turnaround Time of CNC Milling Machines for Aluminum

With CNC milling machines for aluminum, the turnaround time is significantly reduced compared to traditional milling methods. The automation and precision of these machines enable faster cutting speeds and quicker production cycles. This is especially beneficial for industries that require a high volume of aluminum parts, as it allows for faster delivery and response to customer demands.

5. Cost-Effective Solution of CNC Milling Machines for Aluminum

While CNC milling machines for aluminum may have a higher upfront cost, they offer a cost-effective solution in the long run. These machines require minimal maintenance and can operate continuously for extended periods without compromising quality. Additionally, the precision and efficiency of CNC milling machines reduce material waste, further contributing to cost savings.

6. Improved Safety of CNC Milling Machines for Aluminum

Utilizing CNC milling machines for aluminum enhances workplace safety compared to manual milling methods. These machines are equipped with safety features such as automatic tool changers, coolant systems, and enclosures that protect operators from potential hazards. The automation of the machining process also reduces the risk of human error, minimizing the likelihood of accidents.

7. Consistency and Reproducibility

Consistency and reproducibility are crucial in manufacturing processes, particularly when producing aluminum parts. CNC milling machines ensure that each piece is manufactured to the same specifications, eliminating variations that can affect product performance. This consistency is especially important in industries such as aerospace and automotive, where precision and reliability are paramount.

8. Enhanced Surface Finish

CNC milling machines for aluminum are capable of achieving a superior surface finish compared to manual milling methods. With precise control over cutting speeds, feeds, and tool paths, these machines can produce smooth and even surfaces. This is particularly beneficial for industries that require aesthetically pleasing aluminum parts or components that require minimal friction.

9. Reduced Operator Skill Requirements

Operating CNC milling machines for aluminum requires less skill compared to manual milling methods. The automation of the machining process eliminates the need for extensive training and experience in manual milling techniques. This allows companies to quickly train operators and reduce the reliance on highly skilled individuals, ultimately saving time and resources.

10. Integration with CAD/CAM Software

CNC milling machines for aluminum seamlessly integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows for efficient programming and simulation of machining processes. Engineers can create detailed 3D models, generate tool paths, and simulate cutting operations before the actual machining process begins. This streamlines the entire production workflow and enables quick adjustments and optimizations.