Enhanced Productivity

compact horizontal machining centers are designed to maximize efficiency and productivity in the manufacturing process. By having a smaller footprint, these machines can have quicker tool changes and faster cycle times compared to larger machines.

Precision Machining

The compact size of horizontal machining centers allows for more precise and accurate machining. This is especially important in industries that require high precision components, such as aerospace and medical devices.

Cost-Effective Solution

Investing in a compact horizontal machining center can be a cost-effective solution for businesses looking to improve their manufacturing processes. The smaller size means less energy consumption and reduced maintenance costs.

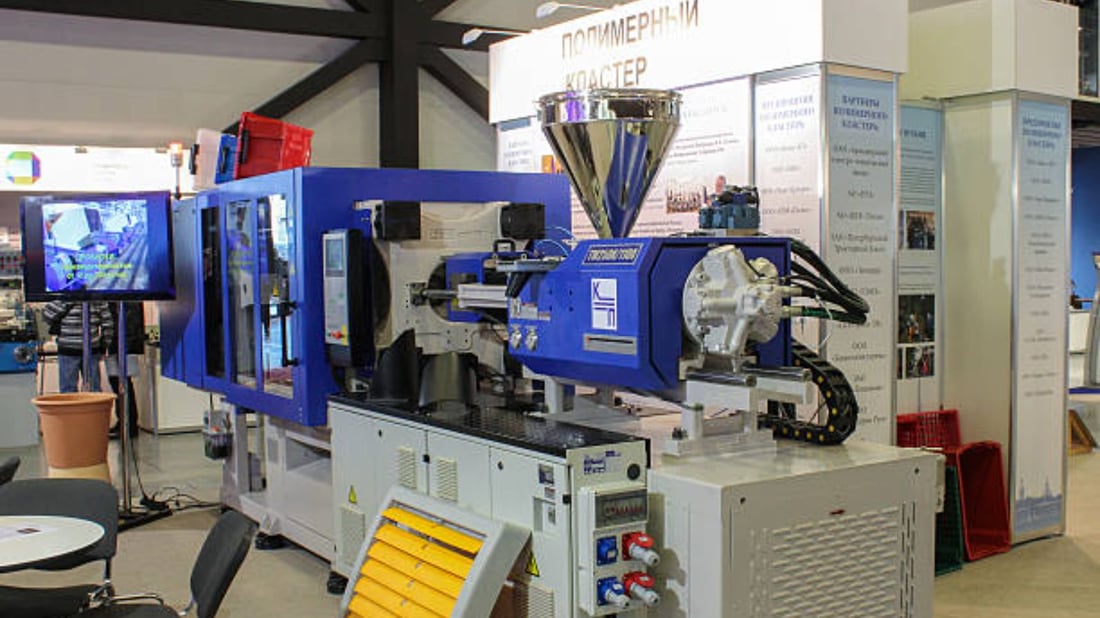

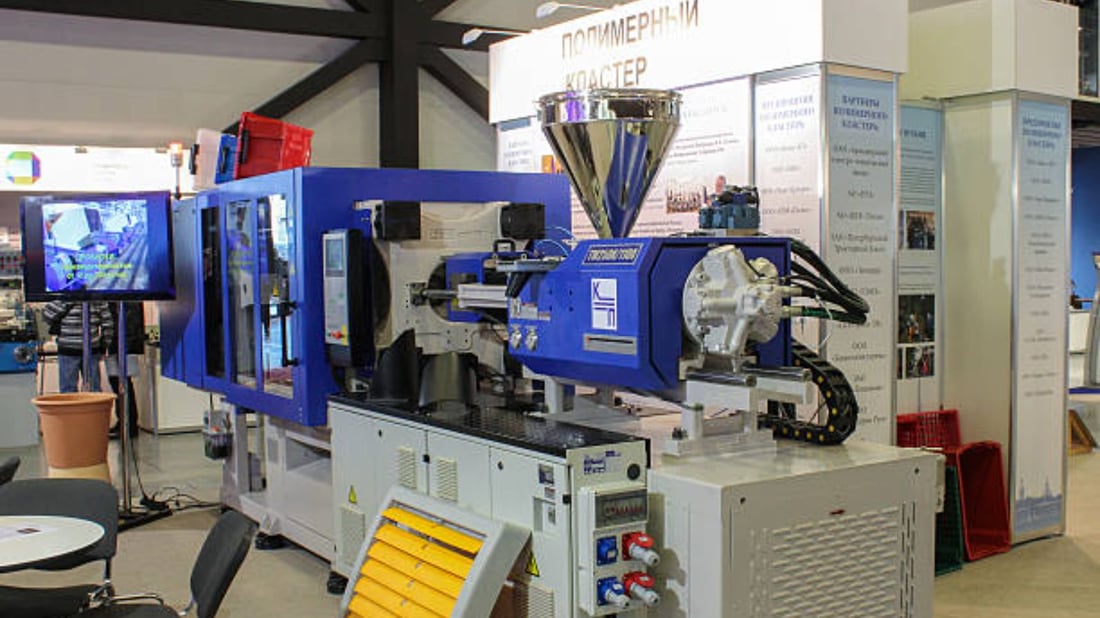

Space-Saving Design

One of the biggest advantages of a compact horizontal machining center is its space-saving design. These machines can fit into smaller workspaces, making them ideal for smaller manufacturing facilities or workshops.

Versatile Machining Capabilities

Despite their compact size, horizontal machining centers are capable of a wide range of machining operations. They can handle various materials and complex part geometries, making them versatile machines for different industries.

Improved Operator Safety

Compact horizontal machining centers are designed with operator safety in mind. Features such as automatic tool changers and coolant systems help to reduce the risk of accidents in the workplace.

Efficient Chip Handling

The design of compact horizontal machining centers also includes efficient chip handling systems. This ensures that chips are safely and effectively removed from the work area, reducing the risk of damage to the machine or workpiece.

High-Speed Machining

With advancements in technology, compact horizontal machining centers are now capable of high-speed machining. This means faster cutting speeds and reduced cycle times, leading to increased productivity.

Automation Integration

Many compact horizontal machining centers can be easily integrated with automation systems. This allows for unmanned operation, increasing productivity and efficiency in the manufacturing process.

Energy Efficiency

Compact horizontal machining centers are designed to be energy-efficient, with features such as energy-saving motors and automatic power-off functions. This helps reduce energy costs and minimize the environmental impact of manufacturing operations.

Quote Inquiry

Contact us!