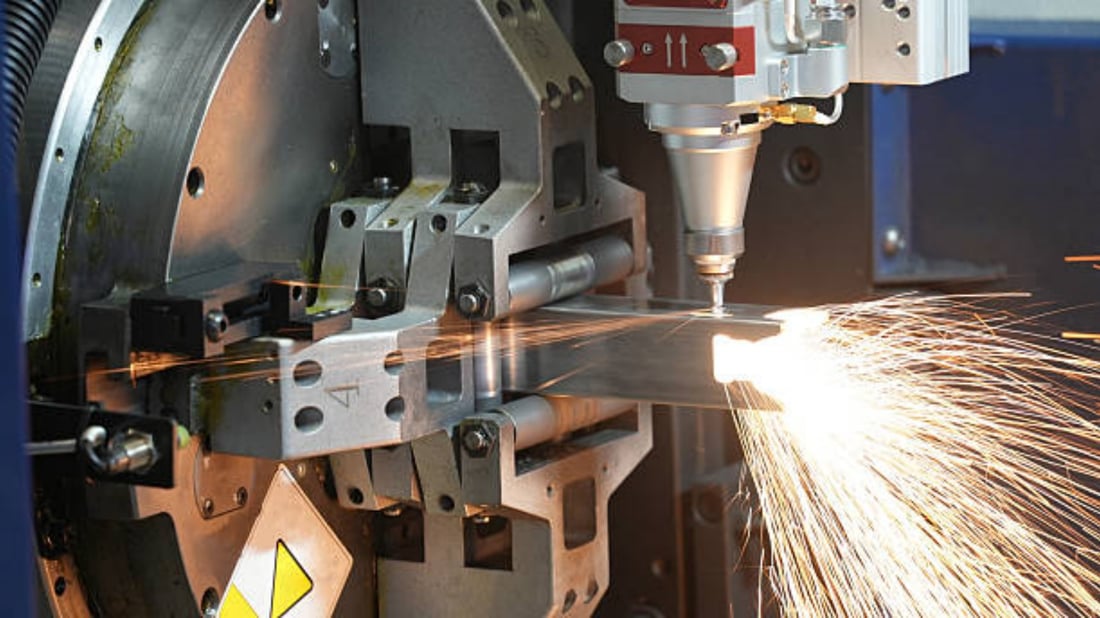

Understanding the Basics of Pipe Laser Cutting

Pipe laser cutting is a highly precise method of cutting cylindrical metal pipes using focused laser beams. Unlike traditional cutting methods, it provides superior accuracy, minimal heat-affected zones, and clean edges. Familiarizing oneself with the fundamental principles of laser technology and pipe geometry is crucial to achieving optimal results. Understanding aspects such as laser types, wavelengths, and beam quality significantly impacts cutting performance.

Choosing the Right Laser for Pipe Cutting

Selecting the appropriate laser power and type is essential when working with different pipe materials and diameters. Fiber lasers are widely favored for their high efficiency and ability to cut reflective metals, while CO2 lasers remain effective for thicker, non-metallic pipes. Matching the laser specifications to pipe thickness and type ensures clean and efficient cuts, reducing wastage and rework.

Optimizing Pipe Positioning and Fixturing

Proper pipe alignment in the laser cutting machine is critical for accuracy. Using specialized pipe clamping and rotary fixtures allows smooth 360-degree rotation and prevents deformation during cutting. Consistent positioning guarantees uniform cuts along the entire pipe length. Employing automated pipe feeders can enhance production speed and repeatability.

Adjusting Laser Parameters for Different Materials

Material type strongly influences laser settings such as power, speed, and focal position. For instance, stainless steel pipes typically require higher laser power and slower cutting speeds than aluminum pipes. Adjusting parameters based on the pipe’s reflectivity, thickness, and thermal conductivity results in better edge quality, reduced dross, and minimal post-processing.

Maintaining Optimal Focus Distance and Beam Quality

Ensuring the laser beam maintains the correct focal distance to the pipe surface is vital for achieving precise cuts. Misalignment can cause kerf widening, poor edge finish, and incomplete cuts. Regular calibration of the focusing optics and monitoring beam quality provide consistent cutting performance and help extend machine life.

Utilizing Assist Gases Effectively

Assist gases such as oxygen, nitrogen, or air play a key role in the laser cutting process by clearing molten material and influencing cut quality. Oxygen is often used for ferrous metals to enhance cutting speed through exothermic reactions, while nitrogen prevents oxidation in stainless steel and aluminum. Selecting the right gas type and pressure, tailored to pipe material, improves edge smoothness and prevents contamination.

Ensuring Safety During Pipe Laser Cutting

Laser cutting pipes involves high-powered beams and potentially hazardous fumes. Proper personal protective equipment (PPE) including laser safety glasses, gloves, and ventilation systems are mandatory to protect operators. Additionally, maintaining machine guards and following strict safety protocols minimize risks associated with laser reflections and material handling.

Reducing Thermal Distortion and Warping

Heat generated during laser cutting can cause deformation in thin-walled pipes. Implementing strategies such as using optimized cutting speeds, multiple passes, or pre-cooling can mitigate thermal distortion. Additionally, material selection and pipe design with appropriate wall thickness minimize warping, ensuring dimensional accuracy in the final product.

Post-Processing Techniques for Pipe Laser Cuts

Though laser cutting produces clean edges, certain applications may require post-processing to enhance surface finish or meet tight tolerances. Techniques like deburring, grinding, or polishing remove residual dross and improve aesthetics. Implementing automated post-processing systems can increase efficiency, especially in high-volume production environments.

Maintaining and Troubleshooting Laser Cutting Equipment

Regular maintenance of the laser cutting system, including cleaning lenses, inspecting mirrors, and checking alignment, is fundamental for consistent performance. Troubleshooting common issues such as inconsistent cuts, excessive dross, or beam instability helps avoid costly downtime. Keeping a maintenance log and following manufacturer guidelines prolongs equipment life and ensures reliable pipe laser cutting operations.