Understanding Pipe Laser Cutting Accuracy

Pipe laser cutting accuracy refers to the precision with which laser technology cuts pipes to specified dimensions and tolerances. It is vital in industries where exactness impacts assembly, performance, and safety. High accuracy minimizes material wastage and ensures components fit perfectly in their intended applications, from construction to automotive sectors.

Factors Influencing Pipe Laser Cutting Accuracy

Several factors affect the accuracy of pipe laser cutting, including the quality of the laser source, machine calibration, pipe material, wall thickness, and operator skill. Environmental conditions such as temperature and vibration also play a role. Understanding these influences is crucial for optimizing the cutting process and maintaining tight tolerances.

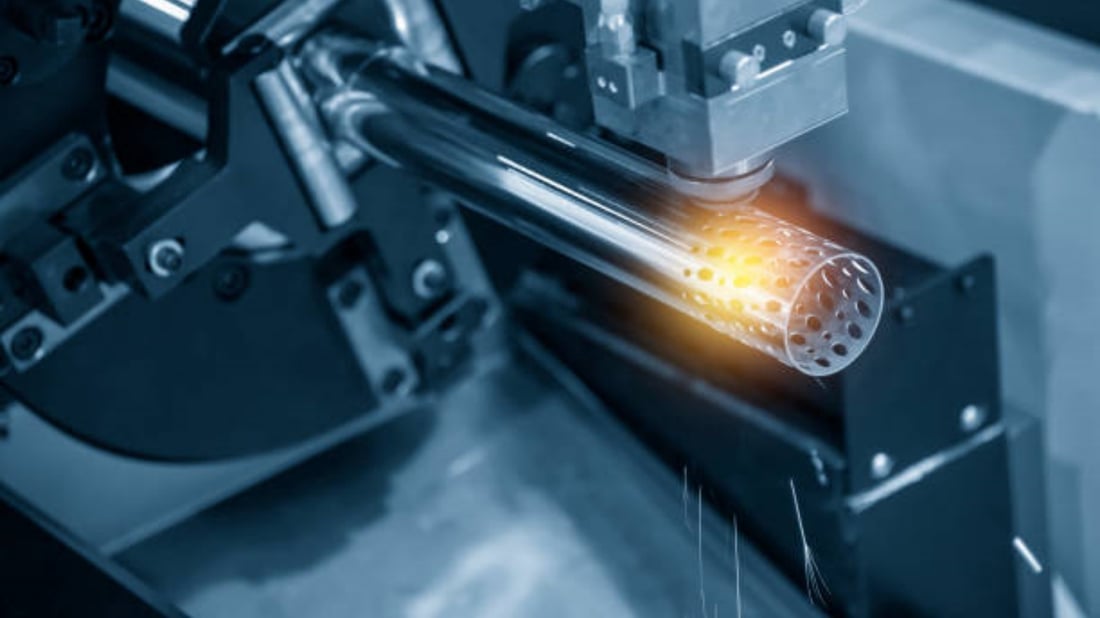

Types of Laser Systems for Pipe Cutting

Different laser systems like CO2 lasers, fiber lasers, and Nd:YAG lasers offer varying degrees of accuracy and efficiency. Fiber lasers typically provide superior accuracy and speed for pipe cutting, especially for thin to medium thickness materials. Selecting the appropriate laser type is fundamental for achieving desired results.

Importance of Machine Calibration in Accuracy

Regular calibration of pipe laser cutting machines is essential to maintain cutting precision. Calibration ensures that the laser aligns correctly with the pipe surface and follows programmed paths accurately. Without routine calibration, deviations can accumulate, negatively impacting product quality.

Material Considerations Affecting Laser Cutting Precision

The material being cut significantly affects laser cutting accuracy. Different metals and alloys respond uniquely to laser energy, with variations in melting points, reflectivity, and thermal conductivity. For instance, stainless steel tends to have better cutting consistency compared to reflective materials like aluminum, which may require adjustments.

Role of Software in Enhancing Accuracy

Advanced CAD/CAM software programs aid in optimizing laser cutting paths and speeds for pipe fabrication. Software tools process design files, simulate cuts, and adjust parameters to improve accuracy and reduce errors. Integration of software with hardware streamlines operations and ensures repeatability.

Impact of Pipe Geometry and Size on Cutting Precision

The diameter, thickness, and curvature of pipes influence laser cutting accuracy. Larger diameters may introduce challenges in maintaining focus and beam stability, while thicker walls demand higher laser power and slower cutting speeds. Customized setups and fixtures are often necessary for intricate geometries.

Common Challenges and Error Sources in Pipe Laser Cutting

Challenges such as thermal distortion, misalignment, and tool wear can compromise pipe laser cutting accuracy. Errors may also arise from improper clamping or movement inconsistencies. Identifying these sources allows operators to implement corrective measures to sustain precision.

Quality Control Measures to Verify Cutting Accuracy

Post-cut inspection techniques, including coordinate measuring machines (CMM), laser scanners, and visual audits, are crucial in verifying pipe laser cutting accuracy. Implementing rigorous quality control protocols ensures that each pipe meets predetermined specifications and helps in continuous process improvement.

Future Trends Improving Pipe Laser Cutting Accuracy

Emerging technologies like AI-driven process control, real-time monitoring sensors, and augmented reality for setup assistance are revolutionizing pipe laser cutting accuracy. These innovations promise higher precision, reduced downtime, and smarter automation, further enhancing industrial applications.