The Basics of a manual cnc milling machine

Manual CNC milling machines are versatile tools used for precision cutting of complex shapes in a range of materials. These machines are a type of subtractive manufacturing process, where material is removed using rotating cutting tools. With the advancements in technology, the manual CNC milling machine has become a popular choice for companies in various industries, from automotive to aerospace, for producing parts and prototypes with detailed designs and complex geometries.

Structure and Components

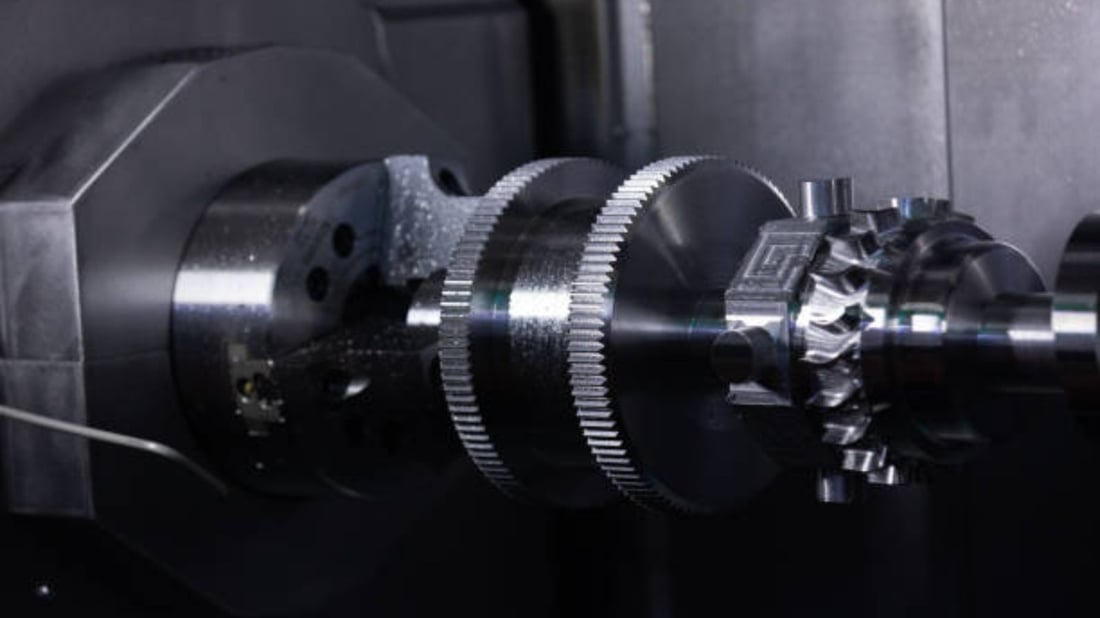

Manual CNC milling machines usually consist of a worktable, a spindle that holds the cutting tool, and various cutting tools, including drills, end mills, and thread mills, among others. The cutting tools rotate and remove material from the workpiece to create the desired shape. The machine is controlled through a computerized numerical control (CNC) system, which allows for precise control of the cutting process.

The Advantages of a Manual CNC Milling Machine

One of the biggest advantages of a manual CNC milling machine is the ability to produce precision parts consistently. The machine operates with high accuracy and can produce parts at a much faster rate than traditional manual machines, reducing lead times and improving productivity. Additionally, the CNC system allows for easy replication of parts and the creation of complex shapes with high accuracy.

Applications of Manual CNC Milling Machines

Manual CNC milling machines are used across various industries, including aerospace, automotive, and medical device manufacturing, among others. These machines can produce parts with high precision and accuracy, making them ideal for creating complex shapes and prototypes. Additionally, manual CNC milling machines are used to repair damaged or worn parts, improving the efficiency of existing machinery.

Factors to Consider when Choosing a Manual CNC Milling Machine

When selecting a manual CNC milling machine, there are several factors to consider. Some key considerations include the size of the machine, the type of materials it can work with, the number of axes it has, spindle speed, and the level of automation it offers. It's important to choose a machine that meets your specific needs and budget.

Key Maintenance Requirements

Regular maintenance is essential for keeping your manual CNC milling machine operating efficiently. It's important to keep the machine clean and properly lubricated to ensure smooth operation and prevent wear and tear. Additionally, routine inspections and calibration can help identify any potential issues before they become major problems.

Safety Considerations

Like any industrial machinery, manual CNC milling machines can be dangerous if not operated correctly. It's important to follow all safety guidelines and use proper protective gear, such as safety glasses and gloves. Make sure to read the owner's manual carefully and receive proper training before operating the machine.

The Future of Manual CNC Milling Machines

The manual CNC milling machine has already revolutionized the manufacturing industry, and advancements in technology and automation are only making these machines more efficient and accessible. Newer models offer increased precision, speed, and versatility, allowing for even more complex shapes and materials to be worked with. The future of manual CNC milling machines looks promising, and they are likely to continue to be a valuable tool for manufacturers across various industries.

Industry Trends and Future Developments

As the demand for precision parts and prototypes continues to grow, manufacturers are looking for ways to increase efficiency and reduce costs. One of the latest trends in manual CNC milling machines is the integration of artificial intelligence (AI) and machine learning algorithms, allowing for even greater precision and automation of the milling process. Additionally, advancements in the use of 3D printing in combination with manual CNC milling machines, also known as hybrid manufacturing, are opening up new possibilities for producing even more complex parts and prototypes.

Conclusion

Manual CNC milling machines are a versatile and reliable tool used across various industries for precision cutting of complex shapes and materials. They offer increased efficiency, accuracy, and productivity than traditional manual machines, and advancements in technology and automation are only making them more valuable. It's essential to choose the right machine for your specific needs and maintain it properly to ensure its longevity and safety.