Laser tube cutter precision refers to the ability of a laser cutting machine to produce clean, accurate, and repeatable cuts on tubular materials. Precision in laser tube cutting is critical because it directly influences the quality of the final product, reduces material wastage, and enhances manufacturing efficiency. The combination of laser technology and advanced control systems allows for micron-level tolerances, making it ideal for industries demanding high accuracy.

Technological Advances Enhancing Precision

Modern laser tube cutters incorporate state-of-the-art technology such as CNC controls, servo motors, and real-time feedback systems. These advancements ensure that operators can achieve exceptional repeatability and accuracy across complex shapes and varying tube profiles. The laser beam's fine focal point allows for minimal kerf width, further contributing to the high precision achievable in tube cutting processes.

Importance of Precision in Industrial Applications

Precise laser cutting is paramount in industries like aerospace, automotive, medical devices, and construction where even minor deviations can compromise structural integrity or function. Laser tube cutter precision ensures components fit perfectly during assembly, reducing the need for secondary finishing operations and lowering production costs. This accuracy promotes reliability and safety in end products, which is especially vital in critical applications.

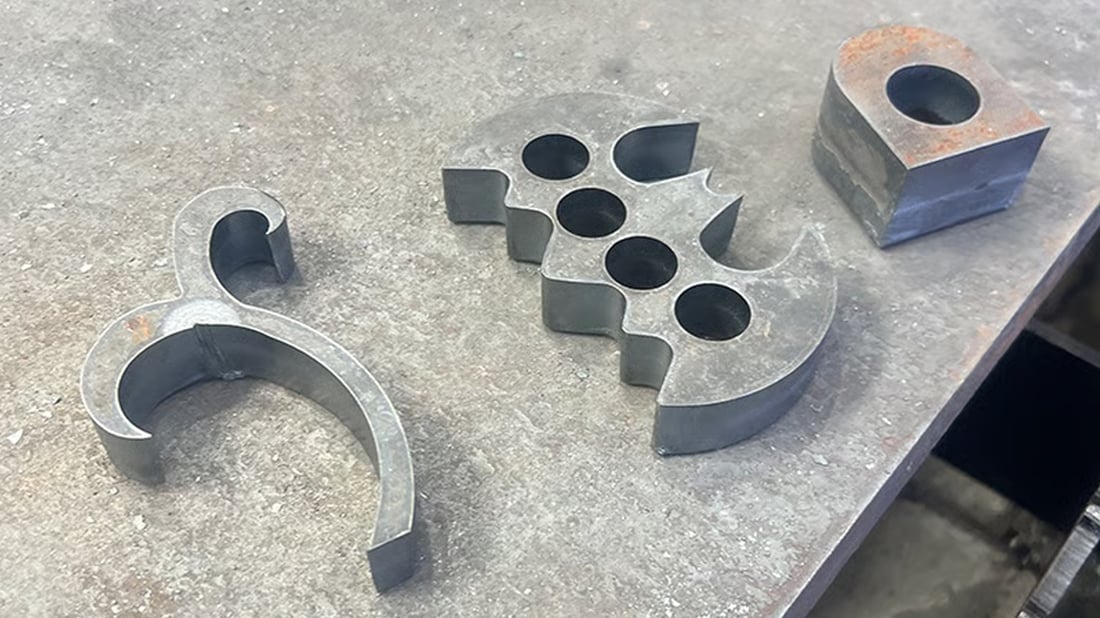

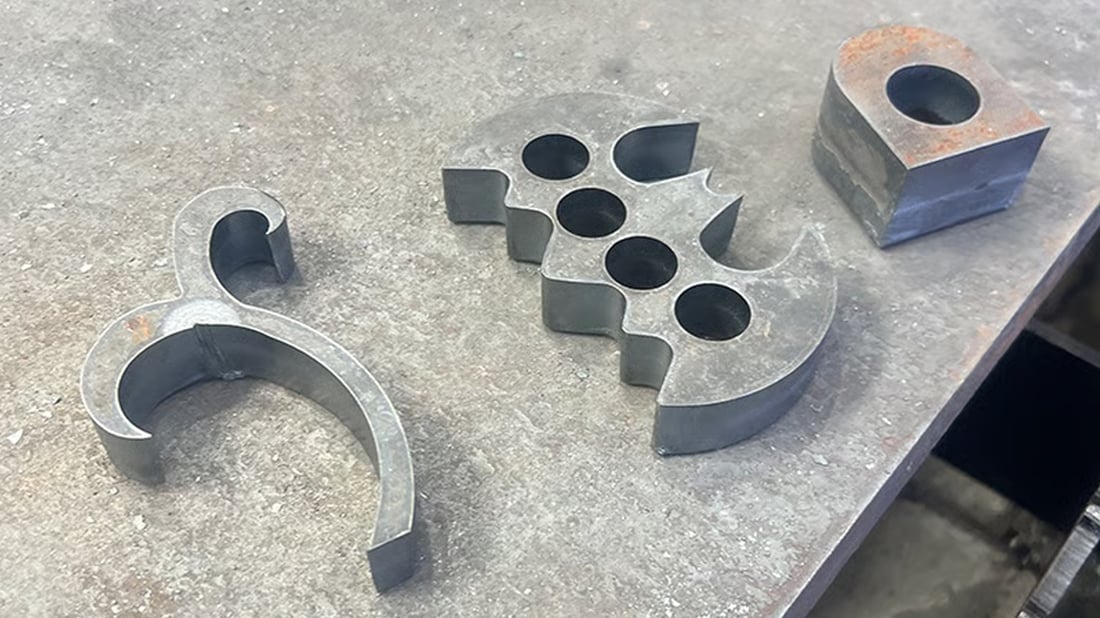

Materials Best Suited for Laser Tube Cutter Precision

Laser tube cutters deliver excellent precision across a range of materials including stainless steel, aluminum, brass, copper, and titanium. The laser’s versatility allows precision cutting of thin-walled and thick tubular materials alike. Selecting the right laser type, power, and cutting parameters tailored to the specific material enhances the precision and reduces the risk of thermal distortion during the cutting process.

Factors Affecting Laser Tube Cutter Precision

Several factors influence the precision of laser tube cutting, including laser power, focal length, cutting speed, and the quality of tube surface preparation. Machine rigidity and proper clamping of the tube also play crucial roles in minimizing vibrations and movement during cutting. Additionally, software algorithms governing path control can optimize precision by adjusting cutting parameters in real-time.

Role of Software in Enhancing Cutting Precision

Advanced software integrated with laser tube cutters facilitates precise programming of cutting paths and machining sequences. CAD/CAM software allows engineers to design complex geometries that the machine follows exactly, ensuring minimal deviation. Simulation capabilities help predict potential errors, allowing adjustments before actual cutting, which improves overall precision and reduces costly errors.

Quality Control and Measurement Techniques

To guarantee laser tube cutter precision, thorough quality control measures are implemented using coordinate measuring machines (CMM), laser scanners, and optical comparators. These tools verify dimensional accuracy, edge quality, and surface finish. Establishing precise inspection protocols ensures each cut meets the stringent tolerances required, providing consistent production quality over large batches.

Benefits of High Precision Laser Tube Cutting

High precision laser tube cutting offers multiple benefits including reduced thermal distortion, enhanced edge quality, and increased manufacturing speed. Precision reduces material scrap rates and the need for post-processing, resulting in cost savings. It also enables more intricate designs and tight assembly fits, opening opportunities for innovative product development and competitive advantage.

Challenges in Achieving Consistent Precision

Despite technological advances, certain challenges persist in maintaining consistent laser tube cutter precision. These include factors like material inconsistencies, mechanical wear, and environmental conditions such as temperature and humidity. Regular machine maintenance, calibration, and operator training are vital to overcoming these challenges and sustaining optimal cutting precision.

Future Trends in Laser Tube Cutter Precision

The future of laser tube cutter precision lies in the integration of AI, machine learning, and IoT for predictive maintenance and adaptive cutting control. Emerging laser sources such as ultrafast lasers promise even finer precision with minimal heat-affected zones. Moreover, advanced automation will enable seamless integration into smart factories, further improving accuracy, throughput, and customization capabilities in tube cutting.

Quote Inquiry

contact us