When we think of manufacturing, we often picture large factories filled with workers manufacturing goods manually. However, with the advancement of technology, these traditional manufacturing practices have evolved into something much more efficient and accurate. One of these technological innovations is the industrial cnc laser cutter, which has revolutionized the manufacturing industry. In this article, we will discuss the various aspects of an industrial CNC laser cutter and why it is the future of manufacturing.

What is an Industrial CNC Laser Cutter?

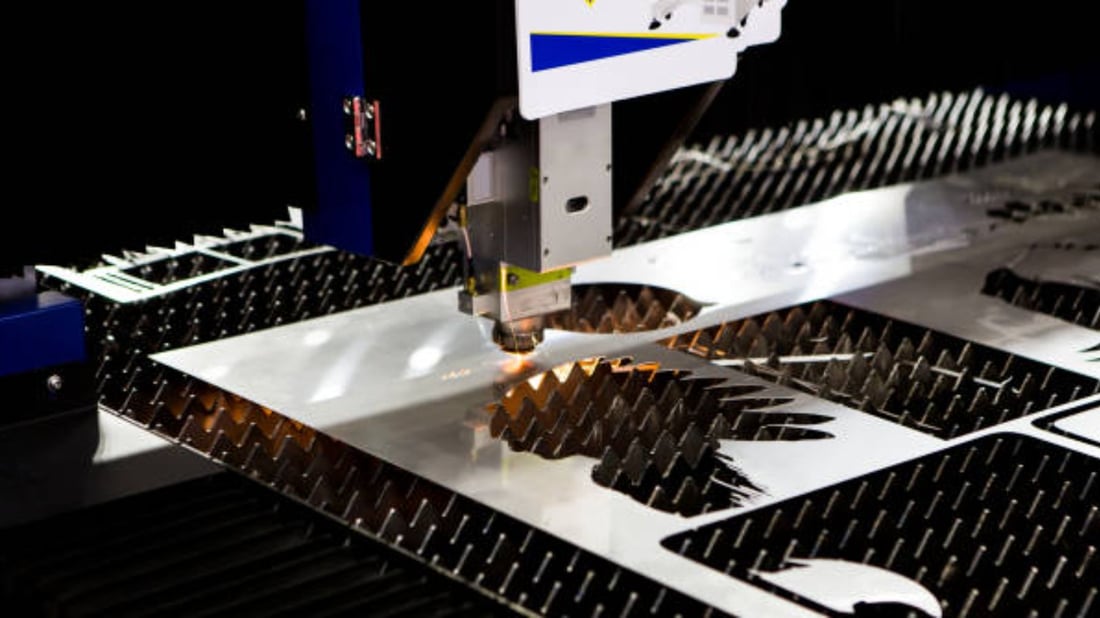

An industrial CNC laser cutter is a precise cutting tool that uses a high-powered laser beam to cut through materials such as metal, wood, and plastic. It is controlled through computer numerical control (CNC) technology and can create complex designs with astonishing precision. These machines can be used for a wide range of applications, including industrial manufacturing, construction, automotive, and aerospace industries.

How Does an Industrial CNC Laser Cutter Work?

The process of an industrial CNC laser cutter is straightforward. The laser beam is directed through a series of mirrors and lenses until it reaches the material, which is positioned on a movable platform. The laser beam then vaporizes or melts the material, creating a precise cut. The CNC technology controls the laser beam's intensity, speed, and position, which ensures accuracy, consistency, and repeatability.

What Materials Can an Industrial CNC Laser Cutter Cut?

An industrial CNC laser cutter can cut through a wide variety of materials, including metal, wood, plastic, and many more. The thickness of the material that the laser cutter can cut depends on the power of the laser beam, with higher power lasers being able to cut through thicker materials. The laser cutter's versatility makes it a valuable tool in many industries, where it can cut through materials that were once thought impossible to cut precisely.

What are the Benefits of an Industrial CNC Laser Cutter?

An industrial CNC laser cutter offers several benefits, making it superior to traditional manufacturing methods. One advantage is precision, as the laser cutter can produce highly accurate cuts with a thickness of up to a few microns. Another benefit is speed, as the laser cutter can perform cuts at a significantly faster rate than traditional methods. Additionally, the laser cutter's versatility and automation capabilities make it a valuable asset in many manufacturing workflows.

What are the Applications of an Industrial CNC Laser Cutter?

An industrial CNC laser cutter has a wide variety of applications in many industries, including cutting and welding metal, wood, and plastic components for various products. It is also used in the automotive industry to cut steel and aluminum components, in the aerospace industry to produce complex components for aircraft, and in the construction industry to cut and engrave materials for architectural designs. The laser cutter's precision and versatility make it invaluable in many manufacturing processes.

What Factors Should You Consider When Choosing an Industrial CNC Laser Cutter?

Several factors should be considered when choosing an industrial CNC laser cutter, including power, size, and precision. The laser cutter's power determines its cutting capabilities, with higher powered lasers being able to cut through thicker materials. The size of the machine and its cutting bed determine the maximum size of the material that can be cut. Finally, one should consider the laser cutter's precision, as this will determine how accurate the cuts will be. All these factors should be balanced against your specific manufacturing needs and budget.

What are the Advancements in Industrial CNC Laser Cutter Technology?

Industrial CNC laser cutter technology is constantly improving, with advancements in automation, precision, and speed. One of the latest innovations is the use of fiber lasers, which offer even higher cutting speeds and more precise cuts. Additionally, advancements in 3D laser cutting technology now allow manufacturers to cut complex three-dimensional shapes with high precision.

Why is an Industrial CNC Laser Cutter the Future of Manufacturing?

Industrial CNC laser cutters offer unparalleled precision, speed, and versatility, making them a valuable asset in many manufacturing workflows. As technology advances and laser cutter technology continues to improve, it will only become more dominant and essential in manufacturing. With the increasing demand for accurate, efficient, and reliable manufacturing processes, an industrial CNC laser cutter is the future of manufacturing.

Conclusion

An industrial CNC laser cutter is a technological leap forward in manufacturing, offering precision, speed, and versatility that traditional manufacturing methods cannot match. With many different applications, an industrial CNC laser cutter is valuable in various industries. As technology advances, we can expect even more innovations in industrial CNC laser cutter technology, further solidifying its position as the future of manufacturing.