The Gantry 5 axis cnc machine L2518: Revolutionizing Precision Manufacturing

The Gantry 5 Axis CNC Machine L2518 is a cutting-edge piece of equipment that has taken the manufacturing industry by storm. With its advanced technology and precision capabilities, this machine has revolutionized the way various industries produce their products. In this article, we will delve into the various aspects of the Gantry 5 Axis CNC Machine L2518 and explore how it has become an indispensable tool in modern manufacturing processes.

Unleashing the Power of 5 Axis Machining

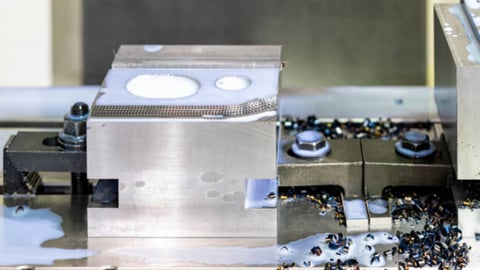

The Gantry 5 Axis CNC Machine L2518 is designed to perform complex machining operations with utmost precision. Unlike traditional 3-axis machines that can only move in three directions (X, Y, and Z), the 5-axis machine adds two additional axes of motion (A and B). This allows the machine to rotate the workpiece and approach it from multiple angles, resulting in greater flexibility and accuracy during the manufacturing process.

Enhanced Productivity of 5 Axis Machining with Gantry Design

The gantry design of the L2518 machine offers several advantages over other CNC machine configurations. The gantry structure consists of a horizontal beam that spans the entire length of the machine, supported by vertical columns on either side. This design provides exceptional stability and rigidity, reducing vibrations and ensuring high-quality machining. Additionally, the gantry design allows for a larger workspace and enables the machine to handle larger workpieces, increasing productivity and versatility.

Precision Engineering for Intricate Parts

Precision is crucial when it comes to manufacturing intricate parts, and the Gantry 5 Axis CNC Machine L2518 excels in this aspect. With its advanced control systems and high-resolution feedback sensors, the machine can achieve micron-level accuracy. This level of precision ensures that even the most complex geometries and tight tolerances can be achieved consistently, making it an ideal choice for industries such as aerospace, automotive, and medical device manufacturing.

The Power of Simultaneous Machining of 5 Axis Machining

One of the key advantages of the Gantry 5 Axis CNC Machine L2518 is its ability to perform simultaneous machining operations. With its multi-axis capabilities, the machine can execute multiple operations on a workpiece simultaneously, reducing cycle times and increasing efficiency. This feature is particularly beneficial in industries where time-to-market is critical, allowing manufacturers to deliver high-quality products to their customers in a shorter timeframe.

Unparalleled Versatility and Flexibility of 5 Axis Machining

The Gantry 5 Axis CNC Machine L2518 offers unparalleled versatility and flexibility in manufacturing processes. Its ability to approach a workpiece from various angles eliminates the need for multiple setups, reducing changeover time and increasing overall productivity. Additionally, the machine can handle a wide range of materials, including metals, plastics, and composites, making it suitable for a diverse range of industries.

Efficiency through Automation and Integration

The integration of automation technology in the Gantry 5 Axis CNC Machine L2518 further enhances its efficiency. With advanced software and control systems, the machine can automate various tasks, such as tool changes, workpiece positioning, and quality inspection. This not only reduces human error but also allows manufacturers to achieve consistent results and optimize production processes for maximum efficiency.

Advanced Tooling Capabilities of 5 Axis Machining

The Gantry 5 Axis CNC Machine L2518 is equipped with advanced tooling capabilities that enable it to tackle a wide range of machining operations. The machine can accommodate various cutting tools, including drills, end mills, and routers, allowing manufacturers to perform intricate milling, drilling, and cutting operations with ease. Additionally, the machine can also perform advanced operations such as 3D contouring, surface machining, and engraving, expanding its capabilities and versatility.

Optimized Workflow with CAD/CAM Integration

CAD/CAM integration plays a vital role in maximizing the potential of the Gantry 5 Axis CNC Machine L2518. By seamlessly integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) software, manufacturers can streamline the workflow, from design to production. The machine can directly import CAD models, allowing for precise replication of complex geometries. CAM software optimizes toolpaths, reducing machining time and minimizing material waste, resulting in a highly efficient manufacturing process.

Investing in the Future of Manufacturing 5 Axis Machining

The Gantry 5 Axis CNC Machine L2518 represents the future of precision manufacturing. With its advanced technology, unmatched accuracy, and versatility, this machine has become an indispensable tool for industries striving for excellence. By investing in this cutting-edge equipment, manufacturers can stay ahead of the competition, deliver high-quality products, and unlock new possibilities in their respective fields.