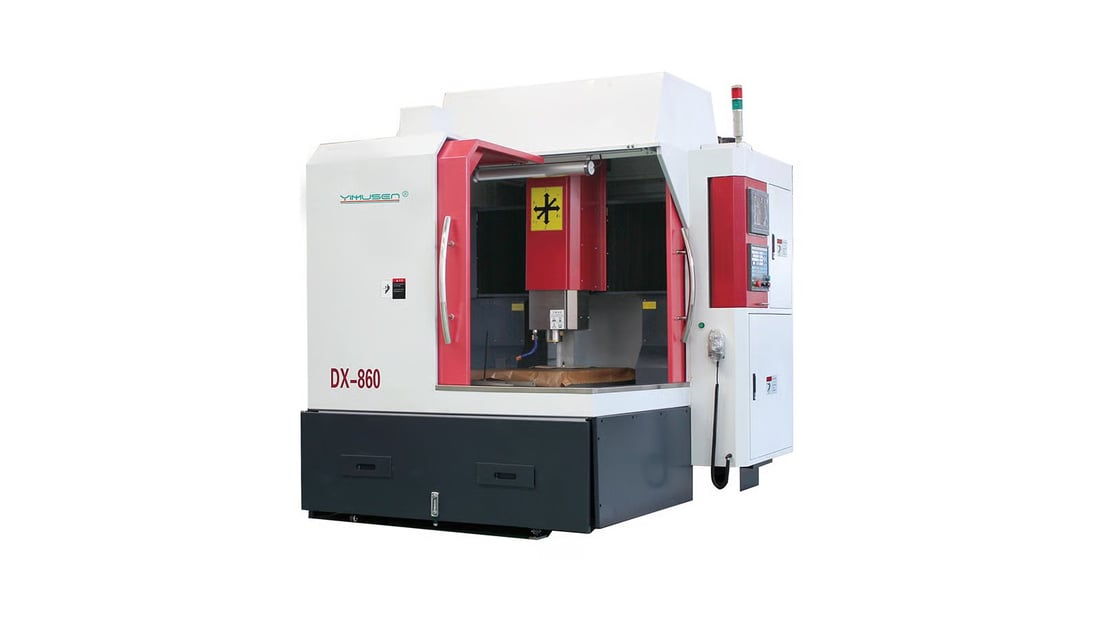

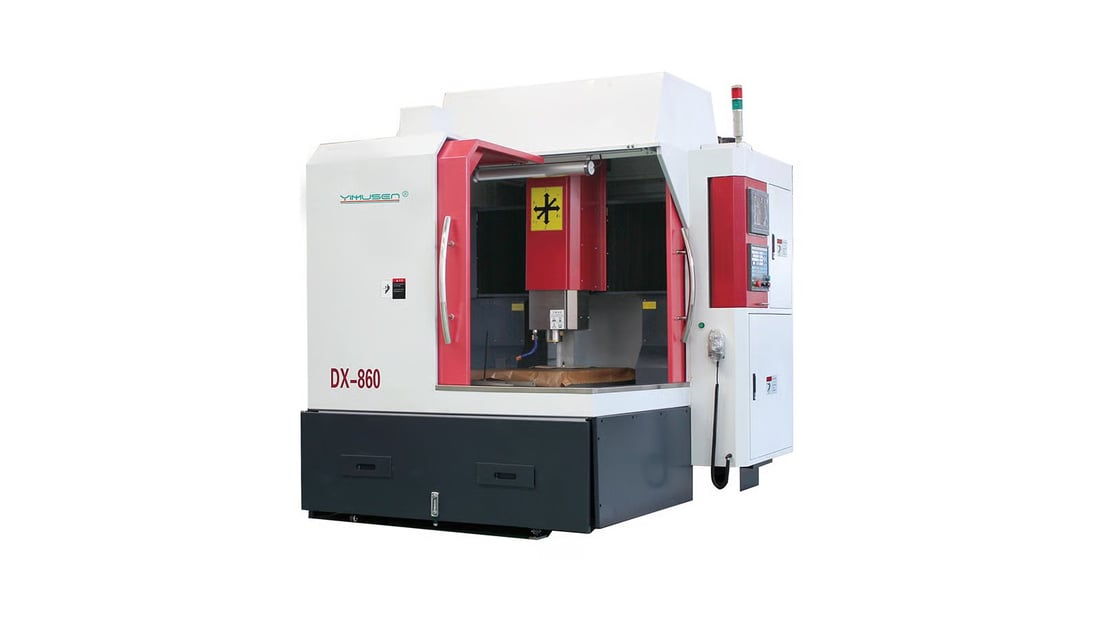

Automatic CNC machining centres offer numerous advantages over traditional machining methods. These cutting-edge systems combine computer numerical control (CNC) technology with automation, allowing for higher precision, increased productivity, and reduced downtime. By automating the machining process, manufacturers can achieve consistency in production, minimize human error, and improve overall quality control.

Enhanced Productivity and Efficiency

One of the key benefits of using an automatic CNC machining centre is the significant increase in productivity and efficiency. These advanced systems are capable of operating continuously, 24 hours a day, 7 days a week, with minimal supervision. By optimizing cutting speeds, tool changes, and other machining parameters, manufacturers can maximize output and reduce lead times, ultimately improving their bottom line.

Precision Machining at its Finest

Automatic CNC machining centres are renowned for their superior precision and accuracy. With the ability to follow complex CAD/CAM designs with pinpoint accuracy, these cutting-edge systems can produce parts and components with tight tolerances and intricate geometries. Whether machining prototypes or mass-producing parts, manufacturers can rely on automatic CNC machining centres to deliver consistent, high-quality results.

Versatility and Flexibility

Another advantage of automatic CNC machining centres is their versatility and flexibility. These advanced systems can accommodate a wide range of materials, including metals, plastics, composites, and more. With the ability to perform multiple operations, such as milling, drilling, tapping, and turning, manufacturers can streamline their production processes and reduce the need for multiple machines, saving time and money.

Cost-Effective Manufacturing Solutions

Investing in an automatic CNC machining centre can lead to significant cost savings in the long run. By automating repetitive tasks and optimizing machining processes, manufacturers can reduce labor costs, minimize material waste, and improve overall efficiency. Additionally, the ability to produce high-precision parts in a single setup can eliminate the need for secondary operations, further lowering production costs.

Improved Safety and Ergonomics

Automatic CNC machining centres prioritize safety and ergonomics in the manufacturing environment. With features such as interlocking safety guards, automatic tool changers, and remote monitoring capabilities, these advanced systems help reduce the risk of accidents and injuries in the workplace. By enhancing operator safety and comfort, manufacturers can create a more productive and sustainable working environment.

Remote Monitoring and Control

One of the key features of automatic CNC machining centres is their remote monitoring and control capabilities. Manufacturers can access real-time data on machine performance, production status, and tooling conditions from anywhere in the world. By leveraging this connectivity, operators can optimize machining processes, troubleshoot issues, and minimize downtime, keeping production running smoothly.

Integration with Industry 4.0 Technologies

Automatic CNC machining centres are at the forefront of Industry 4.0, the fourth industrial revolution that emphasizes automation, connectivity, and data exchange in manufacturing. By integrating with advanced technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing, these cutting-edge systems can enhance efficiency, facilitate predictive maintenance, and enable smart manufacturing practices.

Sustainability and Environmental Responsibility

In an era of increasing environmental awareness, automatic CNC machining centres offer sustainable manufacturing solutions. By optimizing cutting parameters, reducing energy consumption, and minimizing material waste, manufacturers can reduce their carbon footprint and operate more environmentally friendly facilities. With automated processes and advanced recycling capabilities, these systems support a greener, more sustainable future.

The Future of Manufacturing

As technology continues to evolve, automatic CNC machining centres will play a pivotal role in shaping the future of manufacturing. With their unmatched precision, efficiency, and flexibility, these advanced systems enable manufacturers to stay competitive in a rapidly changing market. By embracing automation and innovation, companies can unlock new opportunities for growth and success in the digital age.

Quote Inquiry

contact us