An Automated Tube Cutting Line is a highly efficient system designed to streamline the cutting of metal tubes through automated processes. By integrating cutting-edge machinery with computer-controlled precision, this technology revolutionizes manufacturing workflows, significantly reducing manual labor and enhancing productivity in industries such as automotive, aerospace, and construction.

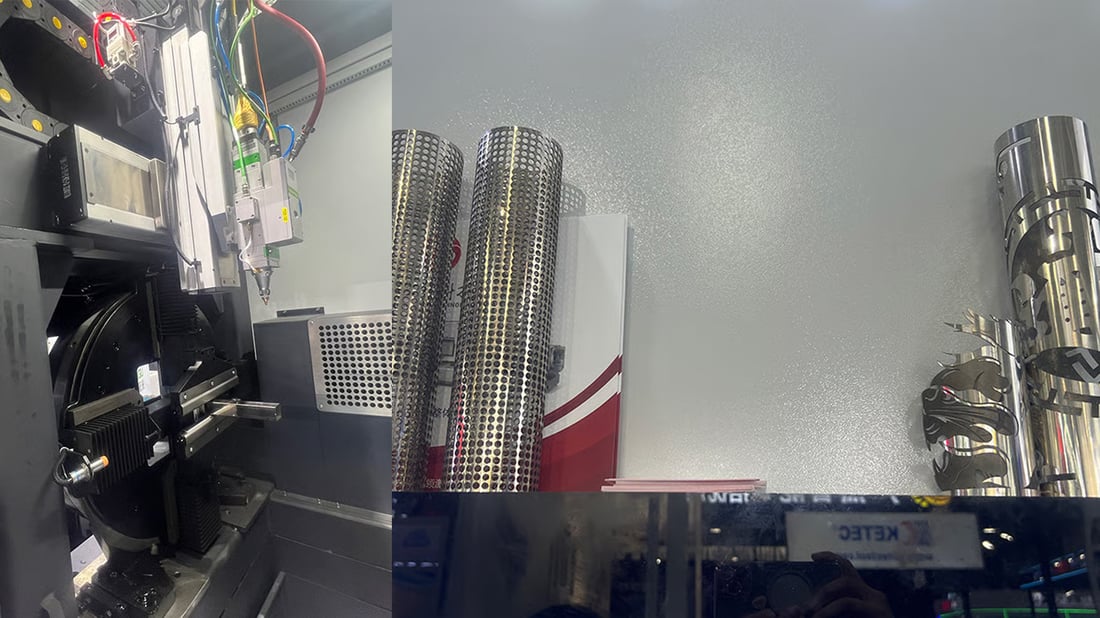

The core of an Automated Tube Cutting Line comprises several critical components including CNC cutting machines, robotic arms, feeder systems, and automated conveyors. These elements work in unison to feed, measure, cut, and sort tubes without human intervention, ensuring consistent quality and rapid throughput.

One of the main benefits of an Automated Tube Cutting Line is its unparalleled precision. Computer Numerical Control (CNC) technologies allow for extremely accurate cuts with minimal tolerances, which is essential for applications that demand exact specifications. Consistency in cut length and angle reduces product defects and improves assembly fit.

Automated Tube Cutting Lines dramatically reduce production time compared to manual cutting methods. Automation minimizes waste and errors, cutting down on material costs and reducing labor expenses. This efficiency helps manufacturers meet tight deadlines and scale production with lower overall expenditure.

These lines are equipped to handle a wide range of tube materials including stainless steel, aluminum, copper, and carbon steel of various diameters and thicknesses. This flexibility makes Automated Tube Cutting Lines suitable for diverse sectors, adapting quickly to different production requirements without major reconfigurations.

Automation in tube cutting significantly reduces workplace hazards by limiting human exposure to sharp tools and heavy machinery. Features such as enclosed cutting chambers, emergency stop systems, and automated error detection create a safer work environment, aligning with stringent safety regulations and minimizing accident risks.

Modern Automated Tube Cutting Lines often incorporate Industry 4.0 technologies such as IoT sensors, real-time monitoring, and data analytics. This integration enables predictive maintenance, remote diagnostics, and process optimization, allowing manufacturers to achieve higher operational efficiency and reduce downtime.

Manufacturers can customize Automated Tube Cutting Lines to meet specific project requirements, including variable tube lengths, complex geometric shapes, and multi-stage processing. Moreover, these systems are scalable, allowing gradual expansion of production capacity to accommodate growing business needs without complete overhauls.

By minimizing waste and optimizing material use, Automated Tube Cutting Lines contribute to environmentally sustainable manufacturing practices. Energy-efficient motors and machinery reduce power consumption, while precise cutting reduces scrap material, helping companies lower their ecological footprint.

The future of Automated Tube Cutting Lines lies in further advancements such as artificial intelligence integration, enhanced robotics, and improved automation software. These developments aim to increase cutting speed, accuracy, and adaptability while reducing human oversight, securing their place as indispensable tools in modern manufacturing.