Introduction: Understanding CNC Milling Machines

CNC milling machines are a vital aspect of modern manufacturing processes, allowing for precise and efficient production of various components and products. In this comprehensive guide, we will delve into the world of CNC milling machine products, exploring their features, applications, and benefits. Whether you are a business owner, a manufacturer, or simply interested in the field, this article will provide valuable insights into the fascinating world of CNC milling machines.

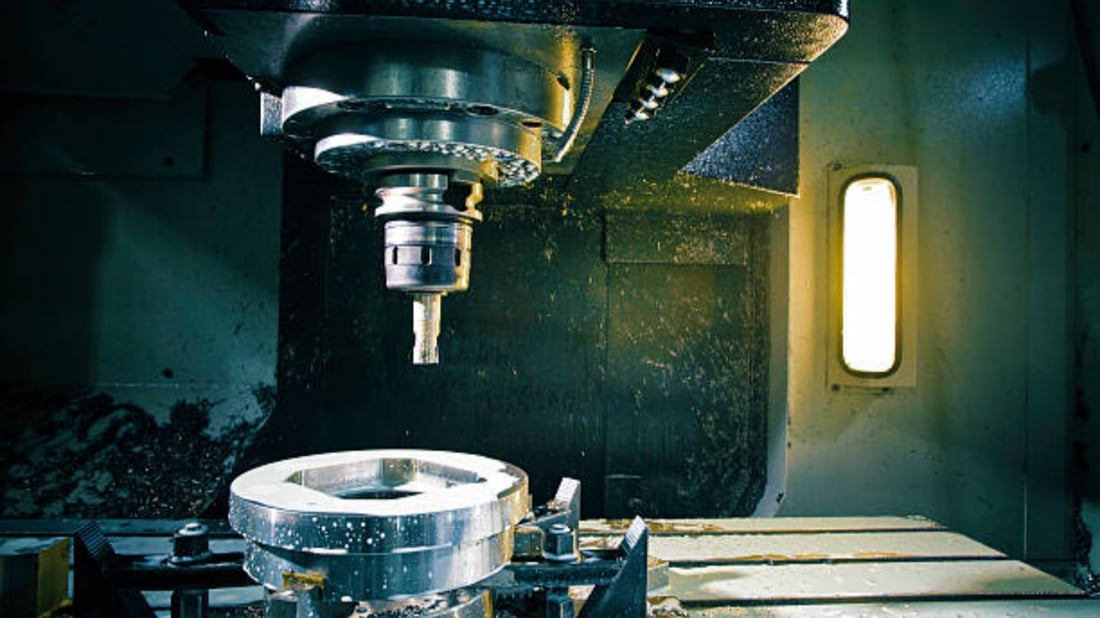

1. What are CNC Milling Machines?

CNC milling machines are automated tools that utilize computer numerical control (CNC) systems to perform precise cutting, drilling, and shaping operations on various materials, such as metal, wood, and plastic. These machines are equipped with rotating cutting tools, which are controlled by a computer program to create complex shapes and designs.

2. Types of CNC Milling Machines

There are several types of CNC milling machines available in the market, each designed for specific applications and requirements. Some popular types include:

Vertical CNC Milling Machines

Vertical CNC milling machines have a spindle that is oriented vertically, allowing for the cutting tool to go straight down into the material. These machines are commonly used for drilling, tapping, and creating deep pockets.

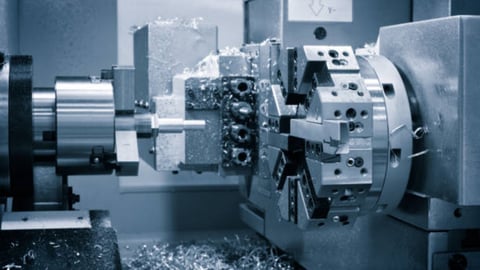

Horizontal CNC Milling Machines

Horizontal CNC milling machines have a spindle that is positioned horizontally, enabling the cutting tool to reach the sides of the workpiece. These machines are ideal for machining large, heavy parts and performing face milling operations.

3-Axis, 4-Axis, and 5-Axis CNC Milling Machines

CNC milling machines can also be categorized based on the number of axes they operate on. 3-axis machines move the cutting tool in three directions: X, Y, and Z. 4-axis machines add rotational movement to the X, Y, and Z axes, while 5-axis machines allow for even more complex movements and angles.

3. Applications of CNC Milling Machine Products

CNC milling machines are widely used in various industries due to their versatility and precision. Some common applications include:

Automotive Industry

In the automotive industry, CNC milling machines are used to manufacture engine components, transmission parts, and intricate body panels. These machines ensure high accuracy and repeatability, resulting in reliable and efficient automotive products.

Aerospace Industry

The aerospace industry relies heavily on CNC milling machines to produce critical parts for aircraft, spacecraft, and satellites. From turbine blades to structural components, CNC milling machines play a crucial role in ensuring the safety and reliability of aerospace products.

Medical Industry

In the medical field, CNC milling machines are utilized to create precise and customized medical implants, prosthetics, and surgical instruments. These machines enable healthcare professionals to provide better patient care by offering tailored solutions.

Electronics Industry

CNC milling machines are also used in the electronics industry to manufacture circuit boards, connectors, and other electronic components. The high precision and speed of these machines contribute to the efficient production of electronic products.

4. Benefits of CNC Milling Machine Products

CNC milling machines offer numerous advantages over traditional manual milling methods. Some key benefits include:

Precision and Accuracy

CNC milling machines can achieve incredibly high levels of precision and accuracy, ensuring consistent quality in the manufactured products. The computer-controlled movements eliminate human error and allow for tight tolerances.

Efficiency and Speed

By automating the milling process, CNC machines significantly reduce production time and increase efficiency. These machines can perform complex operations at a much faster rate compared to manual milling, enhancing productivity.

Versatility

CNC milling machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows manufacturers to produce diverse products and easily switch between different materials and designs.

Cost Savings

Although CNC milling machines may require a significant upfront investment, they offer long-term cost savings. The elimination of manual labor, reduced material waste, and increased production efficiency contribute to overall cost reduction.

Conclusion: Embracing CNC Milling Machine Products

CNC milling machines have revolutionized the manufacturing industry, enabling precise, efficient, and versatile production of various components and products. Whether in the automotive, aerospace, medical, or electronics field, these machines play a crucial role in ensuring the highest quality and reliability of the end products. By embracing CNC milling machine products, businesses can stay at the forefront of technology and meet the ever-evolving demands of the market.