The Rising Demand for Affordable CNC Milling Machines

As the manufacturing industry continues to evolve, businesses of all sizes are constantly looking for ways to improve efficiency and reduce costs. One solution that has gained significant popularity is the affordable CNC milling machine. These machines have revolutionized the way parts and components are manufactured, offering precision, speed, and reliability. In this article, we will explore the various aspects of affordable CNC milling machines and how they can benefit businesses in different sectors.

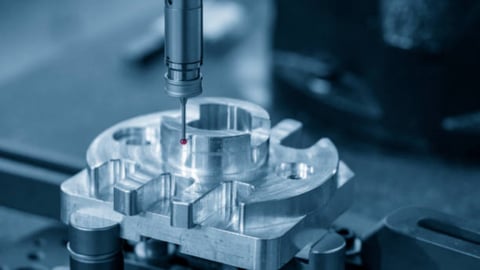

Understanding CNC Milling Machines

CNC milling machines, also known as computer numerical control milling machines, are advanced tools used in the manufacturing industry to shape and cut various materials such as metal, wood, and plastic. These machines operate through a computer program that controls the movement and positioning of the cutting tools. This automation allows for precise and consistent results, making CNC milling machines an integral part of modern manufacturing processes.

Benefits of Affordable CNC Milling Machines

Investing in an affordable CNC milling machine can provide numerous advantages for businesses looking to improve their manufacturing capabilities. Some key benefits include:

1. Enhanced Precision

One of the primary advantages of CNC milling machines is their ability to achieve high levels of precision. These machines can perform complex operations with minimal error, ensuring that the final product meets the strictest quality standards. This precision is particularly crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can have significant consequences.

2. Increased Efficiency

Compared to traditional manual milling methods, CNC milling machines offer significantly higher efficiency. These machines can operate continuously for extended periods, reducing downtime and increasing overall productivity. Additionally, CNC milling machines can perform multiple tasks simultaneously, further improving efficiency and reducing production time.

3. Cost Savings

While the upfront cost of a CNC milling machine may seem substantial, it is important to consider the long-term cost savings. By automating manufacturing processes, businesses can significantly reduce labor costs and minimize the risk of human error. Moreover, CNC milling machines are designed to optimize material usage, resulting in less waste and lower material costs.

4. Versatility

Affordable CNC milling machines are incredibly versatile and can handle a wide range of materials and applications. Whether you need to create intricate metal components or precision-cut wooden parts, these machines can deliver consistent results across various industries. This versatility makes CNC milling machines an attractive option for businesses operating in diverse sectors.

5. Scalability

As your business grows, so does the demand for efficient manufacturing processes. Affordable CNC milling machines offer scalability, allowing you to expand your production capabilities without significant investments in additional equipment or resources. This scalability ensures that your business can meet increasing customer demands while maintaining high-quality standards.

Factors to Consider When Choosing an Affordable CNC Milling Machine

Choosing the right CNC milling machine is crucial to ensure optimal performance and return on investment. Here are some factors to consider when selecting an affordable CNC milling machine:

1. Machine Size and Capacity

Determine the size and capacity of the CNC milling machine based on your specific manufacturing requirements. Consider the maximum workpiece dimensions, spindle speed, and tool capacity to ensure the machine can handle your desired applications.

2. Control System

Look for a CNC milling machine with a user-friendly control system that aligns with your operators' skill levels. An intuitive control system can streamline operations and reduce the learning curve, enabling your team to maximize the machine's capabilities.

3. Tooling Options

Consider the availability and compatibility of tooling options for the CNC milling machine. Having access to a wide range of tools allows for greater flexibility and the ability to perform various machining operations.

4. Maintenance and Support

Ensure that the manufacturer or supplier provides comprehensive maintenance and support services for the CNC milling machine. Regular maintenance and timely support can prolong the machine's lifespan and minimize costly downtime.

5. Price and ROI

While affordability is a key consideration, it is essential to evaluate the overall return on investment (ROI) of the CNC milling machine. Consider the machine's capabilities, durability, and long-term cost savings to make an informed decision that aligns with your budget and business goals.

Conclusion

Affordable CNC milling machines have become indispensable tools for businesses seeking to improve their manufacturing processes. With benefits ranging from enhanced precision and increased efficiency to cost savings and scalability, these machines offer a competitive edge in today's dynamic market. By considering factors like machine size, control system, tooling options, maintenance, and ROI, businesses can choose the right affordable CNC milling machine that meets their specific needs. Embrace the power of CNC milling machines and unlock new possibilities for your manufacturing operations.